Introduction

Water-based inks have risen as a sustainable and environmentally friendly alternative to traditional solvent-based inks in the ever-evolving world of printing. With growing concerns about environmental impact, health, and safety, more companies are turning to water-based inks for flexographic printing. One company that has been at the forefront of this shift is Qinghe, which is leading the way in developing innovative water-based ink solutions for the printing industry.

The Rise of Water-Based Inks

The rise of water-based inks can be attributed to their reduced environmental impact, improved safety and health benefits, and enhanced print quality. As more businesses prioritize sustainability and seek safer alternatives for their printing needs, the demand for water-based inks continues to grow.

Water-based inks are also known for their versatility. They can be used on a wide range of substrates, including paper, cardboard, and fabric. This flexibility makes them an attractive option for businesses looking to streamline their printing processes and reduce the need for multiple types of ink. Additionally, water-based inks are easier to clean up and maintain, saving businesses time and resources in the long run. With these practical advantages, it's no wonder more companies are switching to water-based inks for their printing needs.

Advantages of Water-Based Inks

Water-based inks are becoming increasingly popular due to their numerous advantages for the environment and those who use them. Here are some of the key benefits of switching to water-based inks:

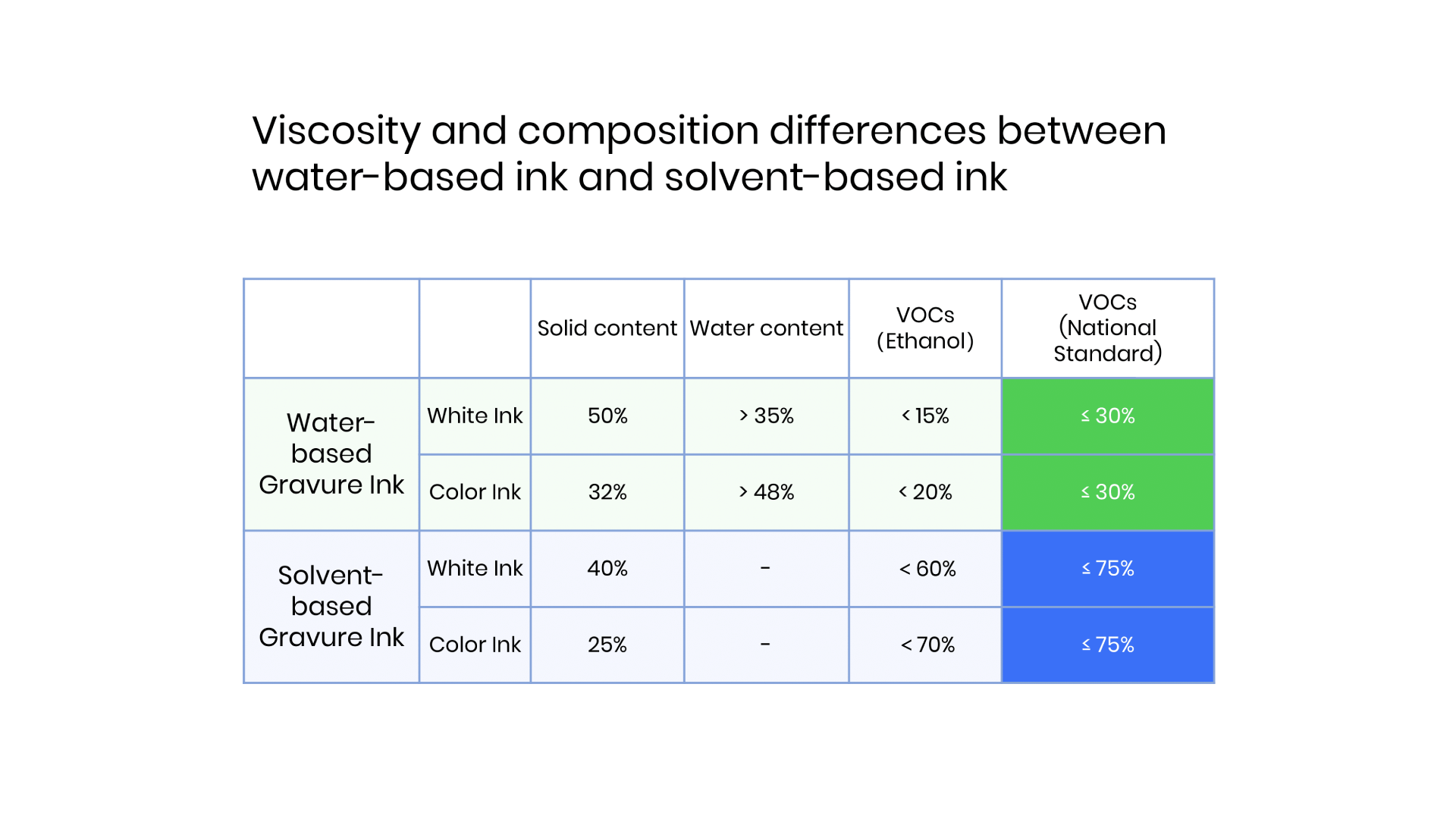

- Safer for People and the Planet: Water-based inks are nontoxic, nonflammable, and emit significantly fewer volatile organic compounds (VOCs) than solvent-based inks. This reduces health risks for printers and improves indoor air quality, making them a more sustainable choice.

- Vibrant Colors and Strong Adhesion: Water-based inks deliver high-quality results despite their eco-friendly nature. They produce vibrant colors that adhere well to various substrates, ensuring long-lasting and visually appealing prints.

- Increased Efficiency and Productivity: Water-based inks also offer practical benefits for printers. They are easier to clean up and require less maintenance, leading to less downtime and increased productivity. Additionally, their faster drying times allow for quicker job completion.

Improved Work Environment: The absence of strong odors associated with solvent-based inks creates a more pleasant working environment for printing professionals. This can contribute to improved morale and overall well-being.

Water-based inks offer a compelling combination of environmental responsibility, safety, and strong print quality. As technology continues to advance, water-based inks are poised to become the standard for a wide range of printing applications.

Qinghe's Leadership in Water-Based Inks

Qinghe has established itself as a leader in developing high-quality water-based inks for flexographic printing. Their commitment to innovation and sustainability has positioned them as a go-to source for eco-friendly ink solutions that meet the highest performance and reliability standards.

In addition to their commitment to innovation and sustainability, Qinghe's water-based inks offer a range of benefits for flexographic printing. These inks provide vibrant and long-lasting color, ensuring that printed materials maintain their visual impact over time. Furthermore, water-based inks are known for their fast-drying properties, allowing for increased productivity and efficiency in the printing process. This combination of quality and performance makes Qinghe's inks a top choice for businesses looking to elevate the impact of their printed materials while minimizing environmental impact.

Benefits of Using Water-Based Inks

1. Reduced Environmental Impact

One of the key benefits of using water-based inks for flexographic printing is their significantly reduced environmental impact. Unlike solvent-based inks, water-based inks contain fewer volatile organic compounds (VOCs), releasing fewer harmful emissions into the atmosphere. This makes them a more sustainable and eco-friendly choice for printing operations, aligning with the industry's growing demand for environmentally responsible practices.

Water-based inks are also safer for workers to handle than solvent-based inks. This is because they do not contain as many toxic chemicals, reducing the risk of exposure and potential health hazards for employees in the printing facility. By prioritizing water-based inks, companies can create a safer working environment and demonstrate their commitment to employee well-being.

2. Improved Safety and Health

Another advantage of water-based inks is their improved safety and health aspects. Lower levels of hazardous chemicals and odors than traditional solvent-based inks provide a safer working environment for print operators and other personnel involved in the printing process. This reduces potential health risks and contributes to a more pleasant and comfortable workplace atmosphere.

3. Enhanced Print Quality

In addition to their environmental and health benefits, water-based inks offer enhanced print quality that meets or exceeds industry standards. They provide vibrant colors, excellent adhesion to substrates, and superior print resolution, making them suitable for various applications, such as packaging, labels, and commercial printing. The advanced technology behind water-based inks ensures high-quality results that satisfy customer expectations.

Water-based inks are known for producing sharp and vivid colors, making them ideal for creating eye-catching packaging and labels that stand out on the shelf. Their vibrant hues add a pop of color to any design, enhancing the product's overall visual appeal. Additionally, the excellent adhesion of water-based inks ensures that the print stays crisp and clear on various substrates, providing a professional and polished finish that meets the high standards of today's competitive market.

Applications of Water-Based Inks

Water-based inks for flexographic printing are incredibly versatile and have many applications, making them an ideal choice for various industries.

1. Flexible Food Packaging

Water-based inks are perfect for printing on flexible food packaging due to their low odor, low migration, and non-toxic properties. This makes them a safe and sustainable option for food manufacturers looking to meet stringent regulatory requirements while maintaining high-quality packaging.

Water-based inks also offer excellent adhesion to various substrates, ensuring the packaging maintains its integrity throughout the supply chain. This means that food products remain secure and protected, reducing the risk of contamination and spoilage. Additionally, water-based inks are highly versatile and can be customized to create vibrant, eye-catching designs that appeal to consumers. This helps enhance brand visibility and attract attention on crowded store shelves.

2. In-Printing and Compounding

In in-printing and compounding, water-based inks offer excellent adhesion and fast drying time and boast eco-friendly properties. With low volatile organic compounds (VOCs) levels, these inks are a sustainable choice for environmentally conscious printing processes. Additionally, their easy clean-up and minimal impact on air quality make them a preferred option for manufacturers and end-users looking to reduce their carbon footprint.

3. Wide Range of Printing Applications

From labels and tags to corrugated boxes and newspapers, water-based inks can be used in a wide range of printing applications. Their ability to deliver sharp images with minimal dot gain makes them an attractive option for printers seeking superior print quality.

Water-based inks are also known for their fast drying time, which can lead to increased productivity and shorter turnaround times for printing projects. This is especially beneficial for high-volume printing jobs where efficiency is key. In addition, their low odor makes them a more pleasant option for both printers and end-users, creating a more comfortable working environment and enhancing the overall experience of printed materials.

With the rise of water-based inks for flexographic printing, this sustainable solution is revolutionizing the industry with its versatility and eco-friendly benefits.

Future Trends in Water-Based Inks Technology

As the demand for sustainable printing solutions continues to grow, the future of water-based ink technology is poised for significant innovation. Manufacturers are exploring new ink ingredients that offer improved performance and environmental benefits. These advancements are driving the development of water-based inks for flexographic printing, which provide a more eco-friendly alternative to traditional solvent-based inks.

Innovation in Ink Ingredients

Manufacturers invest in research and development to create innovative ink ingredients in response to the increasing demand for water-based inks. These new formulations enhance print quality, color vibrancy, and adhesion while minimizing environmental impact. By incorporating cutting-edge materials and additives, water-based ink for flexo printing is evolving to meet the diverse needs of the packaging and labeling industry.

Development of Troubleshooting Solutions

One key challenge in using water-based flexographic ink is troubleshooting issues related to print quality and performance. To address this, manufacturers focus on developing comprehensive troubleshooting solutions that guide optimizing print settings, resolving color inconsistencies, and ensuring smooth production processes. These solutions aim to streamline the transition to water-based inks by offering tailored support and expertise.

Collaboration with Flexographic Ink Manufacturers

The future of water-based flexo ink manufacturers lies in collaboration with industry partners to drive innovation and adoption of sustainable printing practices. By working closely with flexographic printers and converters, ink suppliers can gain valuable insights into specific application requirements and operational challenges. This collaborative approach fosters the development of customized solutions that cater to a wide range of printing applications while promoting environmental stewardship.

Challenges and Solutions in Water-Based Inks

Overcoming Perceived Limitations

One of the main challenges in using water-based inks for flexographic printing is the misconception that they are not as effective as solvent-based inks. However, with advancements in technology and formulation, water-based inks have proven to be just as efficient and reliable. Educating printers and converters about water-based inks' benefits and capabilities can overcome these perceived limitations and encourage their widespread adoption.

Addressing Print Quality Concerns

Print quality has always been a concern with water-based inks for flexo printing. However, with the right ink ingredients and proper troubleshooting solutions, exceptional print quality can be achieved with water-based inks. By working closely with water-based flexo ink manufacturers, we can ensure that print quality concerns are addressed effectively, making water-based inks a viable option for high-quality printing applications.

Ensuring Compatibility with Various Substrates

Another challenge is ensuring that water-based inks are compatible with various substrates commonly used in flexographic printing. With ongoing research and development, ink manufacturers are continuously improving their compatibility with substrates such as paper, film, and foil. Collaboration between ink suppliers and substrate manufacturers is crucial to ensuring that water-based inks can meet the diverse needs of the packaging industry.

Now that we have discussed some of the challenges associated with using water-based inks for flexographic printing, it's clear that there are viable solutions to address these concerns. By overcoming perceived limitations through education, addressing print quality concerns with innovative ink ingredients and troubleshooting solutions, and ensuring compatibility with various substrates through collaboration, we can pave the way for a future where sustainable and high-quality printing solutions go hand-in-hand.

Qinghe's Commitment to Sustainable Printing Solutions

Water-based inks for flexographic printing have revolutionized the industry, and businesses should embrace this shift towards more sustainable and environmentally friendly solutions. With Qinghe's commitment to sustainable printing solutions, the future of flexographic printing looks bright as we develop innovative water-based ink ingredients and troubleshoot any challenges. Using water-based inks is not just a trend; it's the future of flexographic printing.

Embracing the Shift to Water-Based Inks

It's time for businesses to embrace the shift towards water-based inks for flexographic printing, not only for their environmental benefits but also for their superior print quality and safety advantages. By switching to water-based inks, companies can demonstrate their commitment to sustainability while reaping this innovative technology's benefits.

Qinghe is leading the way in providing sustainable printing solutions by developing and producing high-quality water-based inks for flexographic printing. Focusing on reducing environmental impact and improving safety and health, Qinghe is dedicated to ensuring that businesses have access to cutting-edge, eco-friendly ink options.

The Future of Flexographic Printing with Water-Based Inks

Looking ahead, the future of flexographic printing with water-based inks is full of promise. With ongoing innovation in ink ingredients, troubleshooting solutions, and collaboration with water-based flexo ink manufacturers, we can expect even greater print quality and application versatility. The possibilities are endless as we continue to push the boundaries of what water-based inks can achieve.