Introduction

Are you tired of traditional printing inks that harm the environment and compromise color vibrancy? Say hello to water based ink printing, the eco-friendly solution that offers vibrant colors and a soft feel on textiles. As the future of printing, water based ink is revolutionizing the industry with its sustainable practices and innovative technology.

Benefits of Water Based Ink Printing

Water-based ink printing offers a compelling alternative to traditional printing methods, thanks to its numerous advantages:

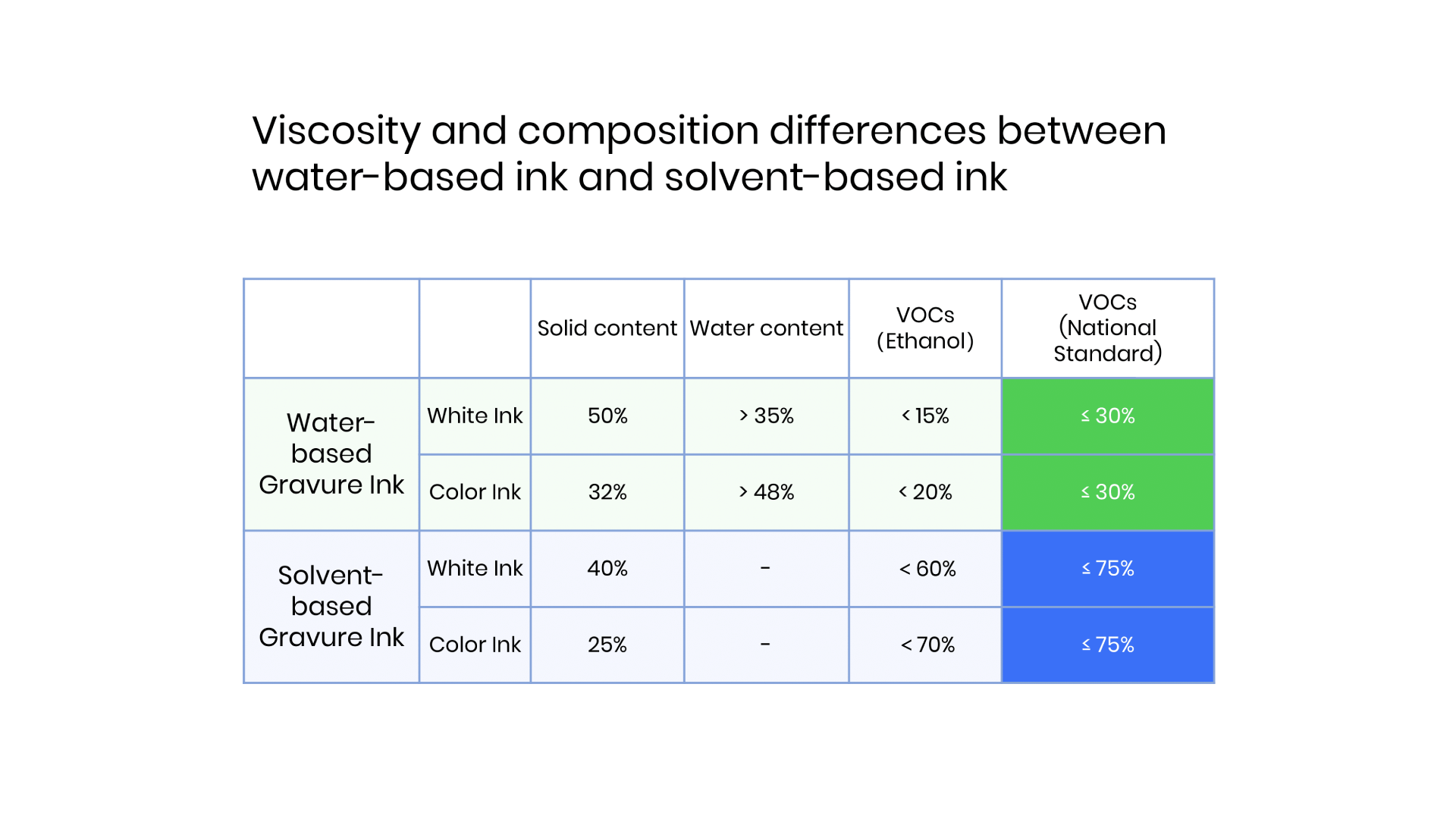

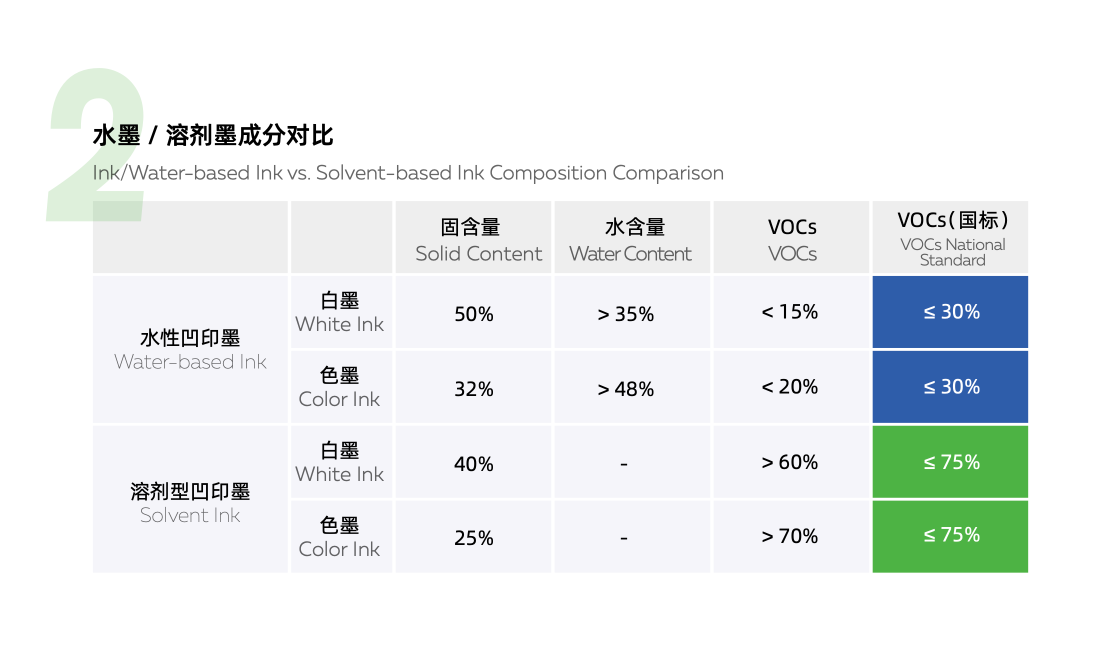

- Environmentally friendly: Water-based inks contain minimal Volatile Organic Compounds (VOCs) and utilize water as the primary solvent. This significantly reduces their environmental impact compared to solvent-based inks, which can release harmful chemicals.

- Vibrant colors: Water-based inks deliver exceptional color reproduction, producing prints with crisp details and a wide color gamut.

- Soft feel on fabrics: Unlike plastisol inks, which can leave a thick, plastic-like texture, water-based inks are dry, thin, and flexible, resulting in a softer and more comfortable feel on textiles like garments and T-shirts.

Water-based ink printing stands out as a sustainable and high-quality solution for textile screen printing. Its eco-friendly properties, vibrant color capabilities, and soft feel on fabrics make it an ideal choice for environmentally conscious businesses and consumers alike.

Qinghe Chemical's Leading Role in Eco-Friendly Inks

Qinghe Chemical has emerged as a leader in developing eco-friendly inks, particularly water based screen printing ink. Their commitment to sustainability and innovation has positioned them at the forefront of the industry, driving positive change through their products.

Water Based Ink: The Future of Printing

With an increasing focus on sustainability and environmental impact, water based silkscreen ink is paving the way for a more eco-friendly future in printing. As consumer demand for sustainable products continues to rise, water based ink is poised to become the standard for textile screen printing.

Water based ink offers a range of advantages that make it the ideal choice for environmentally conscious printing. Not only does it produce vibrant, long-lasting colors, but it also has a softer feel on textiles compared to traditional plastisol ink. Additionally, water based ink is easier to clean up and doesn't require harsh chemicals, making it safer for the environment and those working with it.

Advantages of Water Based Ink

Water-based ink printing offers a multitude of advantages that make it the perfect choice for eco-friendly, high-quality printing. Unlike traditional solvent-based inks, water-based inks are environmentally friendly, as they contain fewer volatile organic compounds (VOCs) and are less harmful to both the environment and human health.

1. Environmentally Friendly

Water based ink for printing is an eco-conscious choice, as it significantly reduces air pollution and minimizes the risk of hazardous waste. With its lower VOC content, water based screen printing ink contributes to a healthier work environment for printers while also aligning with sustainability goals.

2. Vibrant Color and Soft Feel

One of the key benefits of water based silkscreen ink is its ability to produce vibrant colors with a soft feel on textiles. This makes it ideal for creating high-quality prints on fabric, ensuring that designs stand out with their rich hues and smooth texture.

Water based silkscreen ink also offers excellent color retention, ensuring prints maintain their vibrancy even after multiple washes. This durability is a key advantage for textile screen printing, as the colors will remain vivid and eye-catching for a long time. Additionally, the soft feel of the ink on the fabric makes it comfortable to wear, adding to the overall appeal of the printed designs.

3. Ideal for Textile Screen Printing

Fabric ink screen printing has never been easier than with water-based ink. Its ability to adhere to fabric fibers makes it the perfect choice for textile screen printing, providing excellent coverage while maintaining the fabric's natural drape and breathability.

Qinghe Chemical's Innovation in Water Based Ink

Qinghe Chemical is at the forefront of innovation in water based ink for printing, demonstrating a strong commitment to eco-friendly practices. Their dedication to sustainable solutions has led to the development of water based screen printing ink that not only delivers exceptional results but also minimizes environmental impact.

Commitment to Eco-Friendly Practices

Qinghe Chemical's dedication to eco-friendly practices is evident in its development and production of water-based silkscreen ink. By prioritizing the use of environmentally friendly materials and manufacturing processes, it has set a new standard for sustainable ink production in the industry. Its commitment extends beyond simply creating water-based ink; it encompasses a holistic approach to minimizing its ecological footprint.

Rigorous Testing for Food Packaging Safety

In addition to its focus on environmental sustainability, Qinghe Chemical ensures the safety of its water-based ink for printing through rigorous testing, particularly for use in food packaging applications. This commitment to safety and quality control sets it apart as a reliable and responsible provider of fabric ink screen printing solutions that meet stringent regulatory standards.

Transformation of the Printing Industry

Qinghe Chemical is driving a transformation in the printing industry through its dedication to innovation and sustainability. Their development of high-quality water based textile screen printing ink has not only elevated the standard for eco-friendly inks but has also influenced other manufacturers to prioritize sustainable practices. As a result, the industry is moving towards more environmentally conscious solutions.

Furthermore, Qinghe Chemical's commitment to sustainability has also led to advancements in water-based ink technology development. By investing in research and development, they have improved their eco-friendly inks' performance and color vibrancy, making them a competitive alternative to traditional solvent-based inks. This has expanded the options available to printers and demonstrated that sustainable solutions can be just as effective, if not more so, than their conventional counterparts.

Key Features of Water Based Screen Printing Ink

When it comes to water based ink for printing, durability on fabric is a top priority. Unlike traditional solvent-based inks, water based silkscreen ink penetrates the fabric fibers, creating a lasting bond that won't crack or fade over time. This makes it the perfect choice for high-quality textile screen printing that needs to withstand repeated washing and wear.

1. Durability on Fabric

Water based ink's ability to adhere to fabric is unmatched, ensuring your designs stay vibrant and intact after washing. Whether you're printing t-shirts, tote bags, or other textiles, you can trust that your artwork will maintain its integrity over time. Your printed items will look fresh and eye-catching, even after multiple uses and washes. The durability of water based ink on fabric also means that you can confidently offer your products for sale without worrying about the quality diminishing over time.

2. Easy Clean-Up

One of the most appealing aspects of using water-based ink for textile screen printing is the easy clean-up process. Unlike solvent-based inks, which require harsh chemicals for cleanup, water-based inks can be easily washed away with soap and water. This simplifies the printing process and reduces exposure to harmful chemicals for both printers and consumers.

Additionally, water based inks are more environmentally friendly than their solvent-based counterparts. Using water as a base means fewer volatile organic compounds (VOCs) are released into the atmosphere during the printing process. This reduces air pollution and contributes to a healthier work environment for printers. By choosing water based inks, businesses can demonstrate their commitment to sustainability and responsible manufacturing practices.

3. Health and Safety Benefits

The health and safety benefits of water-based ink cannot be overstated. With no volatile organic compounds (VOCs) or hazardous air pollutants (HAPs), this eco-friendly option provides a safer working environment for printers and produces less harm to the planet. Additionally, as more consumers become aware of environmental issues, using water-based ink can be a selling point for businesses looking to appeal to eco-conscious customers.

Exploring Fabric Ink for Printing

When it comes to textile printing, water based ink offers unparalleled versatility. Whether you're working with cotton, polyester, or a blend of fabrics, water based screen printing ink provides excellent adhesion and vibrant colors that truly pop on any textile surface. This makes it ideal for creating custom apparel, home decor items, and more.

Versatility in Textile Printing

Fabric ink screen printing has never been more versatile than with the use of water-based ink. This type of ink can be used on a wide range of textiles, including T-shirts, tote bags, and even upholstery fabrics. Its ability to adhere to different fabric types makes it an essential choice for any textile printer looking to expand its offerings and cater to various client needs.

Enhanced Color Options

Water-based silkscreen ink allows for an extensive range of vibrant and long-lasting color options. The inks can be easily mixed to create custom shades and hues, allowing textile printers to bring their clients' visions to life with precision and creativity.

Sustainable Printing Solutions

In today's eco-conscious world, sustainable printing solutions are in high demand. Water based ink for printing is an environmentally friendly option that aligns with this trend. With its low environmental impact and minimal use of harmful chemicals, fabric ink screen printing is the go-to choice for those seeking sustainable yet high-quality results.

As the demand for sustainable printing solutions continues to grow, water based ink printing is poised to become even more popular. With advancements in technology, water based inks are now able to produce vibrant and long-lasting prints, making them a viable alternative to traditional solvent-based inks. Additionally, as more businesses and consumers prioritize eco-friendly practices, the use of water based ink for printing will likely become a standard industry practice.

The Future of Water Based Ink Printing

As the demand for sustainable printing solutions continues to rise, the use of water-based ink for textile screen printing is becoming a growing trend in the industry. With its eco-friendly composition and vibrant color options, water-based ink is revolutionizing fabric ink screen printing.

Growing Trend in Textile Screen Printing

Textile screen printing with water-based silkscreen ink has gained popularity due to its environmentally friendly nature and high-quality results. More and more businesses are embracing this method to reduce their environmental impact while still achieving vibrant and durable prints on fabric.

Qinghe's Impact on the Industry

Qinghe Chemical's innovative approach to water based ink for printing has had a significant impact on the industry, leading the way in eco-friendly practices and pushing for sustainable solutions. Their commitment to rigorous testing for food packaging safety has set a new standard for water based screen printing ink.

Embracing Eco-Friendly Practices

With an increasing focus on sustainability, many businesses are now prioritizing eco-friendly practices in their operations. Embracing water-based ink not only aligns with this trend but also provides numerous advantages, such as enhanced color options and sustainable fabric ink screen printing solutions.

Conclusion

Embracing Water Based Ink for Sustainable Printing

Water based ink printing is the way of the future, offering eco-friendly and vibrant solutions for textile screen printing. With its environmentally friendly properties and high-quality results, it's time to embrace water based ink for all your printing needs.

Qinghe Chemical's Ongoing Commitment to Eco-Friendly Solutions

Qinghe Chemical has been a trailblazer in developing water-based screen printing ink, leading the industry with its dedication to eco-friendly practices. Its rigorous testing for food packaging safety and commitment to sustainable solutions make it a top choice for all your ink needs.

Advantages of Water Based Ink for Textile Printing

Water-based inks are gaining traction in the textile printing industry due to several key advantages:

- Superior Feel and Detail: Water-based inks penetrate the fabric, resulting in a softer hand (feel) and sharper printed details compared to thicker inks like plastisol.

- Excellent Durability: When properly cured, water-based inks can last as long as the garment, resisting cracking and peeling.

- Environmentally Friendly: Water-based inks contain fewer harmful chemicals and use less energy in production than traditional inks. Additionally, cleanup requires only water, minimizing hazardous waste.

- Vibrant Colors: Water-based inks offer a wide range of colors that can be as vivid as those achieved with solvent-based inks.

Water-based inks provide a sustainable, user-friendly, and high-quality alternative for textile printing. Their superior feel, durability, and environmental benefits make them a compelling choice for businesses and environmentally conscious consumers.

The eco-friendly nature of water based ink also sets it apart from traditional solvent-based inks, making it the environmentally responsible choice for textile screen printing. With increasing consumer demand for sustainable products, using water based ink demonstrates a commitment to reducing environmental impact and meeting the expectations of conscientious consumers. By choosing water based ink, businesses can align themselves with the growing trend towards eco-consciousness and position themselves as leaders in sustainable practices within the industry.