Introduction

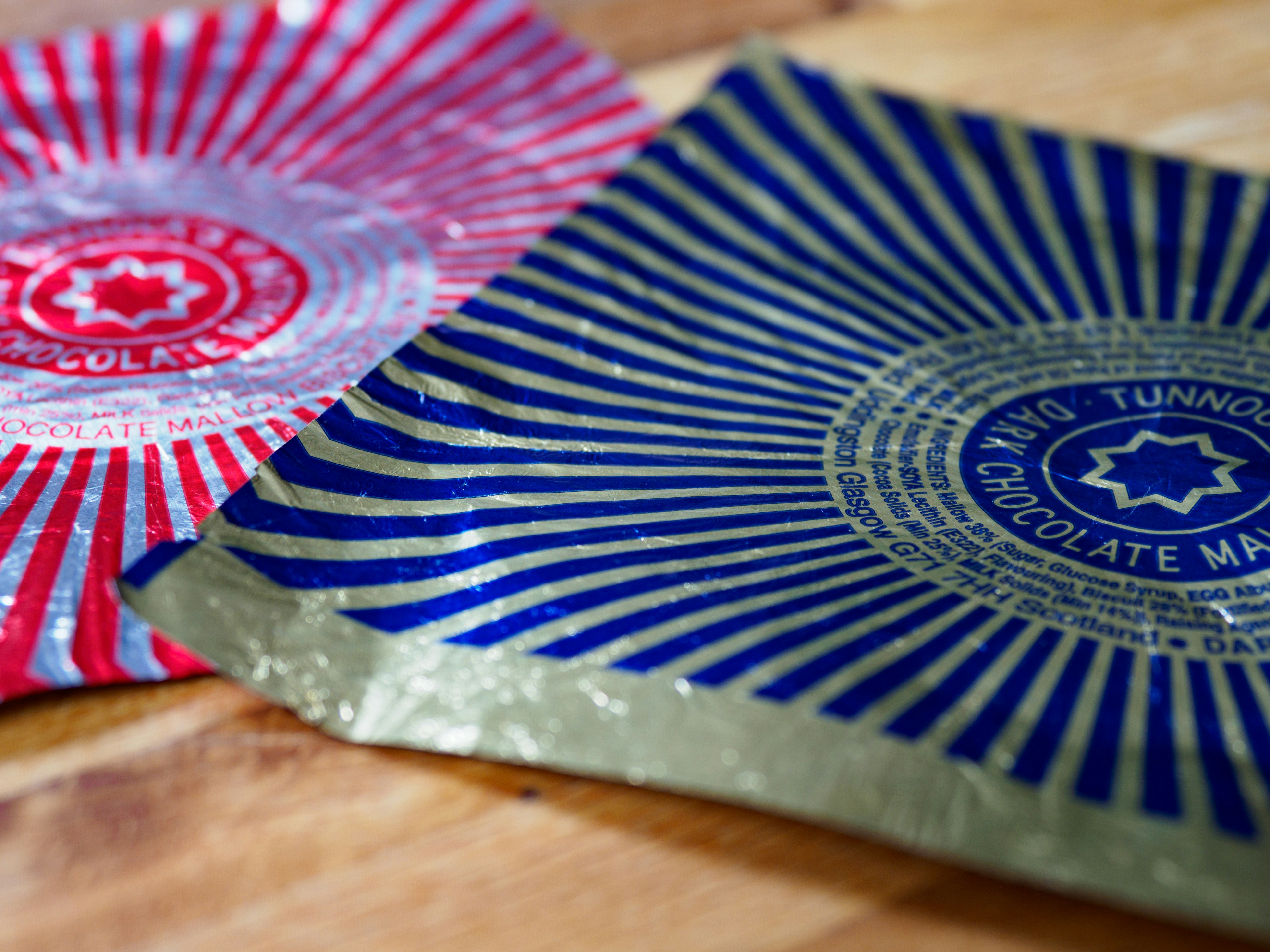

When creating eye-catching packaging, the choice of coating can make all the difference. From acrylic coating to UV coatings, aqueous coatings, specialty coatings, and matte ink, there are plenty of options to explore. Each type of coating offers unique benefits and considerations for enhancing the appeal and durability of printed packaging.

What is

Acrylic Coating?

Acrylic coating is a type of water-based paint made from acrylic polymer emulsion. It is a versatile and popular choice for a variety of applications, including:

- Painting: Acrylic paints are widely used for both indoor and outdoor painting. They are known for their durability, color vibrancy, and ease of use.

- Roofing: Acrylic coatings can be used to extend the life of roofs by protecting them from the elements. They are also reflective, which can help to reduce energy costs.

- Flooring: Acrylic coatings can seal and protect concrete floors. They are also slip-resistant, making them a good choice for high-traffic areas.

- Wood: Acrylic coatings can protect wood from moisture, UV damage, and mildew. They can also be used to create a variety of decorative finishes.

- Metal: Acrylic coatings can protect metal from rust and corrosion and create a variety of decorative finishes.

- Fabrics: Acrylic coatings can waterproof and make fabrics more durable. They can also create a variety of decorative finishes.

Exploring Other Coating Options

Beyond acrylic coating, various other functional coatings such as UV coatings, aqueous coatings, specialty coatings, and matte ink offer distinct advantages for printed packaging. Each type of coating serves different purposes in terms of visual enhancement and protection.

In addition to providing visual enhancement and protection, UV coatings are more environmentally friendly than traditional solvent-based coatings. These coatings are cured instantly with UV light, reducing the need for harmful chemicals and decreasing overall energy consumption. This makes UV coatings a sustainable option for printed packaging, aligning with the industry's growing demand for eco-friendly solutions.

Importance of Printed Packaging

Printed packaging plays a crucial role in brand recognition and consumer perception. The choice of coating can significantly impact the overall look and feel of the packaging, making it essential to consider which option best aligns with your brand image carefully.

Printed packaging not only serves as a functional way to protect and contain products but also acts as a powerful marketing tool. The choice of coating, such as acrylic coating, can enhance the visual appeal of the packaging, making it more attractive to consumers. This can ultimately influence purchasing decisions and contribute to brand loyalty.

Acrylic Coating: The Versatile Choice

Acrylic coating is a popular choice for printed packaging due to its versatility and durability. It provides a glossy finish that enhances the packaging's visual appeal, making it stand out on the shelves. Additionally, the acrylic coating offers excellent protection against moisture and abrasion, ensuring that the printed packaging maintains its quality throughout its shelf life.

Benefits of Acrylic Coating

The numerous benefits of acrylic coating make it a top choice for printed packaging. Not only does it provide a high-gloss finish that enhances the overall look of the packaging, but it also offers excellent protection against wear and tear. Furthermore, an acrylic coating can be easily customized to achieve different levels of glossiness, allowing brands to create unique and eye-catching designs for their products.

Packshine's Experience with Acrylic Coating

At Packshine, we have extensive experience working with acrylic coatings for printed packaging. Our team understands the unique properties of acrylic coatings and how they can be leveraged to enhance printed materials' visual appeal and durability. Our expertise has helped numerous brands elevate their packaging through acrylic coatings, delivering outstanding results that exceed expectations.

Our team at Packshine has honed our skills in understanding the unique properties of acrylic coatings and how they can be effectively used to enhance printed materials' visual appeal and durability. By leveraging our expertise, we have successfully collaborated with numerous brands to elevate their packaging through the strategic application of acrylic coatings. Our outstanding results have consistently exceeded our client's expectations, solidifying our reputation as industry leaders in utilizing acrylic coatings for printed packaging.

Impact of Acrylic Coating on Printed Packaging

The impact of acrylic coating on printed packaging is undeniable. Not only does it enhance the overall aesthetic appeal of the packaging, but it also provides essential protection against external elements such as moisture and friction. This ensures that the printed materials remain pristine throughout their lifecycle, effectively conveying a premium image for the brand.

UV Coatings: Enhancing Visual Appeal

The Role of UV Coatings in Packaging

UV coatings play a pivotal role in enhancing the visual appeal of printed packaging. These coatings are applied to packaging materials and then cured using ultraviolet light, resulting in a glossy and eye-catching finish that captivates consumers at first glance.

Comparing UV Coatings with Acrylic Coating

While acrylic coatings provide versatility, UV coatings offer a more visually striking finish that is especially effective for premium packaging. Unlike acrylic coatings, UV coatings are cured instantly, making them ideal for high-speed printing and ensuring efficient production without compromising quality.

UV coatings also offer superior durability, making them an excellent choice for packaging that needs to withstand handling and shipping. This added protection helps maintain the integrity of the packaging, ensuring that the product remains pristine. Additionally, UV coatings provide a high level of resistance to abrasion, moisture, and chemicals, further enhancing the overall quality and longevity of the packaging.

Advantages of UV Coatings for Printed Packaging

The advantages of UV coatings for printed packaging are numerous. They provide superior protection against wear and tear and enhance the vibrancy of colors and graphics, making the packaging stand out on crowded retail shelves. Additionally, the durability of UV coatings ensures that the visual appeal lasts throughout the product's lifecycle.

UV coatings not only provide protection and enhance visual appeal, but they also offer environmental benefits. Unlike traditional solvent-based coatings, UV coatings are cured using ultraviolet light, which means they contain little to no volatile organic compounds (VOCs). This makes them a more sustainable option for printed packaging, aligning with the growing demand for eco-friendly solutions in the packaging industry. By choosing UV coatings, brands can demonstrate their commitment to sustainability while still achieving high-quality, eye-catching packaging.

With its ability to enhance visual appeal through a glossy finish and vibrant colors, UV coating is essential in creating stunning printed packaging that grabs consumers' attention on retail shelves.

Aqueous Coatings: Eco-Friendly Solution

Sustainability Focus of Aqueous Coatings

Aqueous coatings are gaining popularity due to their eco-friendly nature. They are water-based and emit lower volatile organic compounds (VOCs), making them a sustainable choice for brands looking to reduce their environmental impact while achieving high-quality printed packaging.

How Aqueous Coatings Differ from Acrylic Coating

Unlike acrylic coatings, which are solvent-based, aqueous coatings use water as the main carrier, making them more environmentally friendly. Additionally, aqueous coatings offer a wider range of finishes and can be applied in a thinner layer than acrylic coatings, resulting in a smoother and more uniform appearance.

Aqueous coatings also have the advantage of being more resistant to yellowing over time than acrylic coatings, which can maintain the original appearance of printed packaging for a longer period. This makes them a great choice for products that require a longer shelf life or will be displayed for extended periods. In addition, aqueous coatings are known for their excellent adhesion properties, ensuring that the coating remains firmly attached to the substrate, providing durability and protection to the printed packaging.

Implications of Aqueous Coatings for Printed Packaging

Using aqueous coatings in printed packaging can enhance the aesthetic appeal while protecting against moisture and scuffing. With their ability to create various textures and finishes, including gloss, satin, or matte, aqueous coatings offer versatility for brands looking to elevate the visual impact of their packaging.

When choosing the right coating for your brand's printed packaging, considering the sustainability benefits and visual impact of aqueous coatings can be a game-changer. Opting for eco-friendly solutions that don't compromise quality or aesthetics can reinforce your brand's commitment to innovation and environmental responsibility.

Specialty Coatings: Tailored Solutions

Specialty coatings offer a wide range of customization options for printed packaging, allowing brands to stand out on the shelf. From high-gloss finishes to textured effects, specialty coatings can elevate the visual appeal of packaging and create a unique look and feel.

Customization Options with Specialty Coatings

With specialty coatings, brands can customize their packaging with unique finishes and textures that reflect their brand identity. Whether it's a soft-touch coating for a luxurious feel or a raised UV coating for added dimension, the possibilities for creating eye-catching packaging are endless.

Specialty coatings allow brands to stand out on the shelf with unique finishes and textures that capture their brand's essence. From metallic finishes to matte coatings, brands can use specialty coatings to create packaging that looks great and feels great in consumers' hands. By utilizing specialty coatings, brands can elevate their packaging design to create a memorable unboxing experience for their customers, setting themselves apart from the competition.

Unique Features of Specialty Coatings

Specialty coatings come with unique features such as scuff resistance, tactile enhancements, and even scented coatings that appeal to multiple senses. These coatings can add a layer of protection to printed packaging while providing an interactive and memorable experience for consumers.

Specialty coatings also offer the benefit of customization, allowing brands to create unique and eye-catching designs that stand out on the shelves. Whether it's a high-gloss finish, a matte texture, or a metallic sheen, these coatings can elevate the visual appeal of printed packaging and make a lasting impression on consumers. By incorporating specialty coatings into their packaging design, brands can differentiate themselves from competitors and create a strong brand identity that resonates with their target audience.

Considerations for Specialty Coatings in Printed Packaging

It's important to factor in the overall design and branding goals when considering specialty coatings for printed packaging. The choice of coating should complement the artwork and messaging on the packaging while also aligning with the functional requirements such as durability and sustainability.

By leveraging specialty coatings, brands can create visually stunning printed packaging that captures consumer attention and reinforces brand identity through tactile experiences. These tailored solutions offer endless possibilities for brands looking to make a lasting impression on consumers while ensuring their products are well-protected on store shelves.

Matte Ink: A Durable Finish

Matte ink is a popular choice for printed packaging due to its durability benefits. Unlike other coatings, matte ink provides a scratch-resistant finish that ensures the design stays intact during handling and transportation. This makes it an ideal option for products that require extra protection and longevity.

Durability Benefits of Matte Ink

Matte ink offers exceptional durability, making it resistant to scuffs, scratches, and abrasions. This ensures that the packaging maintains its pristine appearance throughout the product's lifecycle, enhancing brand image and customer satisfaction. With matte ink, brands can confidently deliver their products without worrying about damage to the packaging.

Matte Ink vs. Acrylic Coating for Packaging

When comparing matte ink with acrylic coating for packaging, matte ink stands out as a superior choice in terms of durability and long-lasting protection. While acrylic coating provides a glossy finish, it lacks the same level of resilience as matte ink when preserving the integrity of printed packaging.

Practical Applications of Matte Ink in Printed Packaging

Matte ink is widely used in various industries, such as cosmetics, electronics, and luxury goods, where premium packaging is essential. Its ability to withstand wear and tear makes it ideal for high-end products that require aesthetic appeal and functional protection.

Furthermore, matte ink is an excellent choice for packaging in industries such as food and beverage, where the need for product information and branding is crucial. Its ability to provide a non-reflective surface makes it easier for consumers to read labels and instructions, enhancing the overall user experience. Additionally, matte ink can be combined with other printing techniques to create unique, eye-catching designs that stand out on store shelves.

Conclusion

When it comes to printed packaging, the right coating can make all the difference. Each option has unique benefits and applications, whether you choose acrylic coating, UV coatings, aqueous coatings, specialty coatings, or matte ink. By making informed choices for your printed packaging, you can find the right coating that protects your products and elevates your brand image with premium finishes.

Making Informed Choices for Printed Packaging

Understanding the functional coatings available for printed packaging is crucial in making informed decisions. Each type of coating offers distinct advantages and considerations that can impact the overall look and durability of your packaging. You can ensure that your printed packaging meets your specific needs and requirements by weighing the pros and cons of acrylic coating, UV coatings, aqueous coatings, specialty coatings, and matte ink.

Finding the Right Coating for Your Brand

Finding the perfect coating for your brand involves considering visual appeal, sustainability, customization options, and durability. Whether you prioritize a glossy finish with UV coatings or an eco-friendly solution with aqueous coatings, finding a coating that aligns with your brand's values and aesthetic will enhance the overall presentation of your products. The right coating can elevate your brand's image and leave a lasting impression on consumers.

Elevating Brand Image with Premium Coatings

Premium coatings such as acrylic coating offer sophistication and protection that can set your brand apart from competitors. Investing in high-quality coatings for your printed packaging demonstrates a commitment to excellence and attention to detail. The result is packaging that showcases your products in the best light and reinforces your brand's value and quality.