Introduction

The choice of industrial ink is crucial for achieving high-quality, durable prints in industrial inkjet printing. Understanding how industrial inks are manufactured and their key features is essential for making informed decisions for your business. Factors such as compatibility with printing equipment, specific application requirements, and impact on production efficiency should all be carefully considered when selecting the right industrial ink.

Benefits of Using Industrial Inks

Industrial inks are a game-changer for demanding printing applications. Here's how they excel:

- Superior Adhesion: They bond strongly to various materials, ensuring crisp and durable prints on everything from plastic and metal to glass and textiles.

- Environmental Resilience: Industrial inks are formulated to resist fading, scratching, and chemicals, making them ideal for applications exposed to harsh conditions.

- Vivid Colors: deliver exceptional color reproduction, creating high-impact visuals that grab attention and enhance product appeal.

Industrial inks provide the durability, versatility, and color vibrancy for professional and long-lasting printed materials.

Importance of Choosing the Right Industrial Ink

The importance of choosing the right industrial ink cannot be overstated. Using inappropriate ink can lead to poor print quality, equipment malfunctions, and increased production costs. Selecting the right ink for your specific application is essential for achieving optimal results and maintaining the efficiency of your printing operations.

Factors to Consider When Selecting Industrial Ink

Selecting the right industrial ink is crucial for achieving optimal printing results. Here are several key factors to consider:

- Compatibility: The ink must be compatible with your existing printing equipment to ensure smooth operation and avoid potential damage.

- Application Requirements: Consider specific application needs, such as outdoor durability for weather-resistant prints or chemical resistance for industrial settings.

- Production Efficiency and Cost-Effectiveness: Evaluate factors like drying time, ink consumption, and overall impact on production speed and costs.

These factors will ensure you select the ideal industrial ink for your specific needs, optimizing print quality and production efficiency.

Understanding Industrial Inks

Industrial inks are specifically formulated for inkjet printing, offering unique properties that cater to the demands of industrial applications. Unlike traditional inks, industrial inks are designed to withstand harsh environmental conditions and adhere to a wide range of substrates, making them ideal for use in manufacturing and packaging industries.

What Makes Industrial Inks Different

What sets industrial inks apart is their ability to withstand extreme temperatures, exposure to chemicals, and abrasion resistance. These specialized properties make industrial inks suitable for marking and coding on various materials such as plastics, metals, glass, and even food products. Additionally, industrial inks are engineered to dry quickly and maintain integrity throughout production.

Industrial inks also offer various color options, allowing for customization and branding opportunities. This versatility is essential for industries that require specific color codes or logos to be printed on their products. Whether a vibrant red or a subtle metallic shade, industrial inks can deliver the desired aesthetic while maintaining durability and longevity.

Key Features of Industrial Inks

Key features of industrial inks include high adhesion, fast drying time, excellent lightfastness, and resistance to fading or smudging. These features ensure that the printed codes or marks remain legible and durable even under challenging conditions. Furthermore, industrial inks are available in various colors and formulations to meet specific industry requirements.

In addition to their durability and resistance to fading or smudging, industrial inks are designed to withstand extreme temperatures and harsh environmental conditions. This makes them ideal for use in automotive, aerospace, and manufacturing industries, where printed codes and marks must remain legible even in challenging environments. Whether exposed to high heat, moisture, or chemicals, industrial inks maintain their integrity and ensure the longevity of the printed information.

Types of Industrial Printing Inks

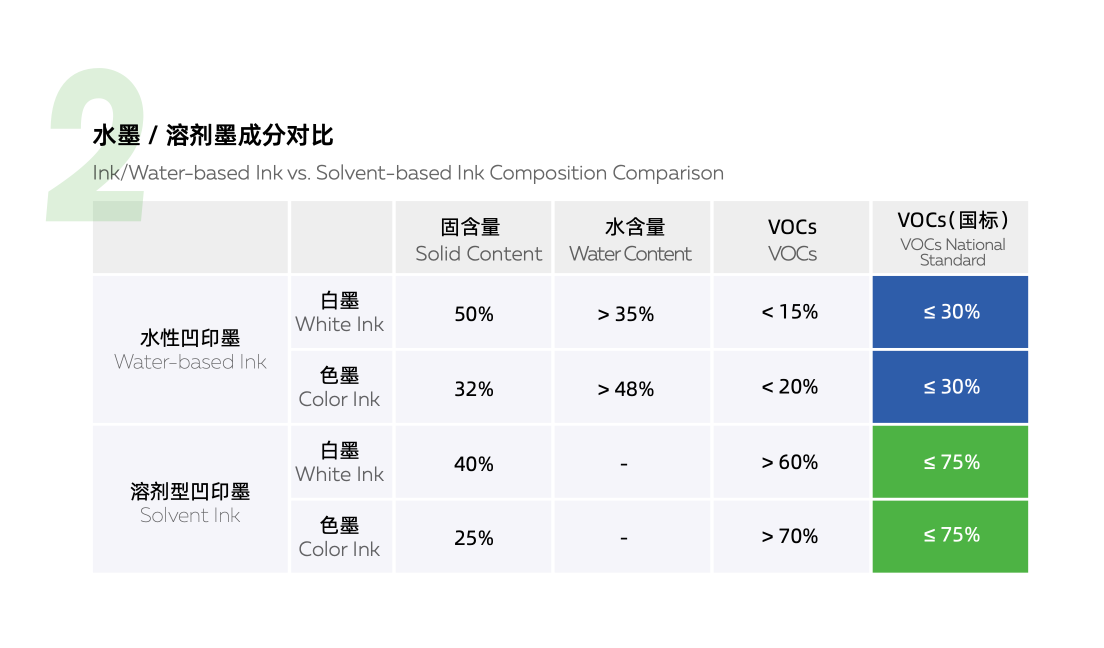

Several types of industrial printing inks are tailored for different applications, such as solvent-based inks, UV-curable inks, water-based inks, and pigment-based inks. Solvent-based inks are known for their durability on non-porous surfaces, while UV-curable inks offer fast curing times and resistance to fading. Water-based inks are favored for their eco-friendly attributes, while pigment-based inks provide vibrant colors with high opacity.

Solvent-based inks are popular because they adhere to non-porous surfaces, making them ideal for applications such as packaging and labeling. Their durability and resistance to abrasion and chemicals make them a top choice for industrial printing needs where longevity is essential. However, it's important to consider the environmental impact of solvent-based inks, as they contain volatile organic compounds (VOCs) that can contribute to air pollution. Despite their effectiveness, businesses may want to explore alternative options that are more eco-friendly.

Now that we have a better understanding of what makes industrial inks unique, their key features, and the different types available, let's move on to exploring the considerations when choosing the right ink for your specific needs.

Choosing the Right Industrial Ink

Compatibility with your printing equipment is crucial when choosing the right industrial ink. Using an industrial ink that is incompatible with your specific printer can result in clogging, poor print quality, and unnecessary downtime. It's important to consult with your equipment manufacturer or supplier to ensure the ink you choose suits your machinery.

A key consideration when selecting industrial ink is its suitability for specific applications. Different industries and products may require different industrial inks, such as those designed for packaging, textiles, or automotive parts. Understanding the specific requirements of your application will help you choose an ink that meets your needs and delivers the desired results.

The impact of industrial ink on production efficiency cannot be overstated. Using high-quality industrial inks formulated for optimal performance can help minimize downtime, reduce maintenance costs, and improve overall productivity. Businesses can maximize their output and profitability by choosing an ink that enhances production efficiency.

Evaluating Ink Quality

Evaluating ink quality is crucial for ensuring optimal performance in industrial inks. Factors affecting ink performance include viscosity, adhesion, and drying time. Viscosity determines how easily the ink flows through the printing equipment, while adhesion refers to how well the ink bonds with the substrate. Drying time is also important, impacting production efficiency and final product quality.

Factors Affecting Ink Performance

Ink performance can be affected by various factors such as temperature, humidity, and substrate material. Temperature and humidity levels in the printing environment can impact ink viscosity and drying time. Different substrate materials may also require specific ink formulations to ensure proper adhesion and color vibrancy.

In addition to temperature, humidity, and substrate material, the type of printing press used can also impact ink performance. Different presses may require different ink formulations to achieve optimal results, so it's important to consider the specific requirements of the printing equipment when selecting an ink. Press speed and pressure can affect how the ink is transferred onto the substrate, ultimately influencing color consistency and overall print quality. Therefore, understanding the capabilities and limitations of the printing press is crucial for achieving the desired results.

Importance of Color Consistency

Color consistency is essential in industrial printing to maintain brand identity and product quality. Inconsistent color matching can lead to rejections and production delays. Industrial ink manufacturers must adhere to strict color standards and quality control measures to ensure that each batch of ink delivers consistent color accuracy.

Shelf Life and Storage Considerations

The shelf life of industrial inks varies depending on their formulation and storage conditions. Proper storage is crucial for maintaining ink quality over time. Light, heat, or air exposure can degrade the ink's performance. Businesses need to consider shelf life and storage requirements when selecting industrial inks for their operations.

Now that we've covered evaluating ink quality let's discuss sustainability and environmental impact in the next section.

Sustainability and Environmental Impact

Qinghe Chemical's Commitment to Sustainability

At Qinghe Chemical, sustainability is at the core of our industrial ink manufacturing process. We are dedicated to reducing our environmental footprint by implementing eco-friendly practices and using renewable resources in our production. Our commitment to sustainability ensures that our industrial inks meet the highest standards for environmental responsibility.

In addition to our efforts to reduce our environmental footprint, we also prioritize the health and safety of our employees and customers. Using water-based industrial inks minimizes the risk of harmful chemical exposure, creating a safer working environment for everyone involved in producing and applying our products. This commitment to safety benefits those directly involved with our inks and contributes to the overall well-being of the communities where our products are used.

Benefits of Using Water-Based Industrial Inks

Water-based industrial inks offer several advantages over traditional solvent-based inks, making them a popular choice for eco-conscious manufacturers. Here's why you should consider switching:

- Environmentally Friendly: Water-based inks are formulated with minimal solvents and chemicals, reducing environmental impact.

- Vibrant Colors & Sharp Images: These inks produce high-quality prints with vivid colors and crisp details.

- Fast Drying Times: Water-based inks dry quickly, boosting productivity and efficiency. This allows for faster turnaround times and reduced labor costs.

- Smudge-Proof Results: The quick-drying nature of these inks minimizes smudging and smearing, ensuring professional-looking printed materials.

Water-based industrial inks offer a sustainable solution for high-quality industrial printing.

Minimizing VOC Emissions

Volatile Organic Compounds (VOCs) are a significant concern in industrial printing ink manufacturing due to their negative impact on air quality and human health. Qinghe Chemical's industrial inks are designed to minimize VOC emissions, ensuring a safer working environment for employees and reducing pollution levels in the surrounding community.

Qinghe Chemical sets a new standard for responsible industrial ink production by prioritizing sustainability and minimizing environmental impact. With water-based options and reduced VOC emissions, businesses can make environmentally conscious choices without compromising quality or performance.

Ensuring Product Safety

Industrial ink manufacturers must prioritize compliance with regulatory standards to ensure the safety of their products. This involves adhering to strict guidelines set by governing bodies to guarantee that industrial inks are safe for use in various applications, such as food packaging and medical devices.

Compliance with Regulatory Standards

Compliance with regulatory standards is crucial for industrial ink manufacturers to gain the necessary certifications and approvals for their products. This entails rigorous testing and documentation to ensure that industrial inks meet the required safety and quality standards, providing peace of mind for businesses and consumers alike.

Impact on Worker Health and Safety

The use of industrial inks can directly impact worker health and safety, particularly when it comes to exposure through inhalation or skin contact. To minimize potential risks in the workplace, manufacturers must prioritize the development of low-toxicity formulations and provide comprehensive training on safe handling practices.

In addition to prioritizing the development of low-toxicity formulations and providing comprehensive training on safe handling practices, manufacturers must also invest in proper ventilation systems and personal protective equipment for workers. Adequate ventilation can help reduce the concentration of harmful fumes in the air, while protective gear such as gloves and masks can minimize skin contact and inhalation risks. By implementing these additional measures, companies can further safeguard the health and safety of their employees in the ink manufacturing environment.

Quality Control in Ink Manufacturing

Quality control measures are essential throughout ink manufacturing to uphold product safety standards. From raw material sourcing to final product testing, stringent quality control protocols help identify potential issues early on, ensuring that only high-quality, safe industrial inks reach the market.

Now you understand how industrial ink manufacturers ensure product safety through regulatory compliance, worker health considerations, and stringent quality control measures. By prioritizing these aspects, businesses can confidently select industrial inks that meet their safety requirements while delivering exceptional performance.

Qinghe Chemical: A Leader in Sustainable Industrial Inks

In conclusion, industrial inks play a crucial role in the success of any industrial inkjet printing operation. The right industrial ink is essential for achieving optimal print quality, production efficiency, and environmental sustainability. With Qinghe Chemical's commitment to sustainable manufacturing and high-quality industrial inks, businesses can make informed decisions that benefit their operations and the environment.

Qinghe Chemical is a leader in sustainable industrial inks, prioritizing eco-friendly formulations without compromising performance. Their water-based industrial inks offer vibrant colors, excellent adhesion, and low VOC emissions, making them an ideal choice for businesses that reduce their environmental impact while maintaining high print quality.

In addition to its commitment to eco-friendly formulations, Qinghe Chemical prioritizes using sustainable packaging for its industrial inks. By utilizing recyclable materials and minimizing waste, they demonstrate a holistic approach to reducing their environmental impact throughout the product lifecycle. This aligns with the growing consumer demand for businesses to offer sustainable products and ensure that their packaging and distribution methods are environmentally responsible.

Making Informed Decisions for Your Business

When selecting the right industrial ink for your business, it's crucial to consider factors such as compatibility with printing equipment, specific application requirements, and overall production efficiency. By staying informed about the different types of industrial printing inks available and evaluating their quality based on color consistency and shelf life, businesses can make confident decisions that positively impact their bottom line. Additionally, considering the environmental impact of different ink options is becoming increasingly important. Choosing eco-friendly inks can reduce your business's carbon footprint and appeal to environmentally conscious consumers, giving your brand a competitive edge in the market.

Finding the Right Industrial Ink for Your Needs

Finding the right industrial ink involves carefully considering various factors such as print equipment compatibility, application-specific requirements, production efficiency impact, and ink quality evaluation based on performance factors like color consistency and shelf life considerations. It's essential to prioritize sustainability and product safety by choosing environmentally friendly options that comply with regulatory standards while promoting worker health and safety.

When considering industrial ink options, it's essential to factor in the potential impact on production efficiency. Choosing an ink that dries quickly and requires minimal maintenance can significantly improve overall productivity. Additionally, selecting an ink with high color consistency can reduce the need for reprints and adjustments, saving both time and resources. Businesses can streamline their operations and boost their bottom line by prioritizing efficiency in the selection process.