Introduction

In today's environmentally conscious world, the demand for low VOC inks is rising. But what exactly does low VOC mean? Low VOC stands for low volatile organic compounds, harmful chemicals commonly found in paint, insulation, and ink. As consumers become more aware of traditional printing methods' potential health and environmental hazards, the need for greener alternatives like low VOC inks has become increasingly important.

The Benefits of Low VOC Inks

Low VOC inks offer a significant advantage over traditional ones for human health and the environment. Here are some key benefits:

- Improved Indoor Air Quality: Low VOC inks emit minimal volatile organic compounds (VOCs), which can irritate the respiratory system and contribute to headaches and dizziness. By switching to low VOC inks, printers and those working in print environments can breathe easier and experience fewer health risks.

- Reduced Environmental Impact: Traditional inks often release harmful pollutants into the air. Low VOC inks minimize these emissions, creating a cleaner and healthier environment.

In conclusion, choosing low VOC inks is a win-win for human health and the planet. By making this switch, printers can create a safer work environment and contribute to a more sustainable future.

Qinghe Chemical: Leading the Way in Greener Printing Solutions

Qinghe Chemical has emerged as a pioneer in developing innovative low VOC ink solutions for sustainable printing practices. With a commitment to reducing environmental impact without compromising print quality, Qinghe Chemical is at the forefront of providing eco-friendly alternatives for the printing industry.

In addition to their low VOC ink solutions, Qinghe Chemical is also dedicated to developing water-based inks that further minimize the environmental impact of packaging printing. By prioritizing water as a solvent, these innovative inks significantly reduce the emission of harmful chemicals into the atmosphere. This forward-thinking approach benefits the environment and aligns with the growing demand for sustainable packaging solutions in today's market.

The Impact of Packaging Printing on the Environment

Packaging printing plays a significant role in consumer goods, but it also poses environmental challenges due to its reliance on high-VOC inks and materials. As more attention is drawn to sustainable packaging solutions, there is an increasing need for low VOC inks that meet regulatory standards and consumer demands for eco-friendly packaging options.

As the demand for sustainable packaging options continues to grow, manufacturers are exploring alternative materials and printing methods to reduce the environmental impact of packaging printing. This includes using bio-based inks derived from renewable resources such as vegetable oils and soybeans, offering a more eco-friendly alternative to traditional petroleum-based inks. Additionally, advancements in digital printing technology have enabled more precise ink application, reducing waste and minimizing the use of harmful chemicals in the printing process.

The Dangers of VOCs in Printing

Volatile Organic Compounds (VOCs) are chemicals that can vaporize into the air, posing health risks to those exposed. In the printing industry, traditional inks and solvents contain high levels of VOCs, leading to respiratory issues, headaches, and even long-term health problems for printers and processors.

Health Risks of VOC Exposure

Exposure to volatile organic compounds (VOCs) can pose a significant health threat, particularly for those working in regularly utilized industries. Here's a breakdown of the health risks associated with VOC exposure:

- Irritation and Respiratory Issues: High levels of VOCs can irritate the eyes, nose, and throat and worsen respiratory problems like asthma.

- Organ Damage: Chronic exposure may lead to liver and kidney damage.

- Central Nervous System Effects: Prolonged VOC exposure can cause dizziness, headaches, and even memory impairment.

- Increased Cancer Risk: Some VOCs are suspected or known carcinogens.

- Environmental Impact: VOC emissions contribute to ground-level ozone formation, harming air quality.

By prioritizing low-VOC inks and solvents, printers, and processors can significantly reduce these health risks and create a safer work environment while minimizing their environmental impact.

Environmental Impact of VOC Emissions

Aside from the health risks, VOC emissions from printing contribute to air pollution and smog formation. These emissions also react with other atmospheric pollutants, leading to ground-level ozone formation, which can harm vegetation and ecosystems. Low VOC inks help reduce these harmful emissions, making them a more environmentally friendly choice.

Regulatory Standards for VOC Emissions in Printing

In response to the dangers posed by high levels of VOCs in printing processes, regulatory standards have been implemented to limit emissions. Many countries have set maximum allowable limits for VOC content in printing products, pushing the industry towards adopting low or zero VOC alternatives like low voc insulation or low voc ink.

Remember that embracing sustainable solutions like low VOC insulation or using low-voc ink isn't just about compliance; it's about protecting your health and our environment while meeting consumer demand for eco-friendly packaging options.

Advantages of Low VOC Inks

Low VOC inks are a game-changer in the printing industry, offering a safer and more sustainable alternative to traditional inks. Low VOC refers to inks with low volatile organic compound content, which means they release fewer harmful chemicals into the air during printing. This is especially important for indoor air quality and overall environmental impact.

Reduced Health Risks for Printers and Processors

Low VOC inks significantly reduce health risks for printers and processors by minimizing exposure to toxic fumes. Traditional inks containing high levels of VOCs can lead to respiratory issues, headaches, dizziness, and other health concerns among those working with them. Switching to low VOC inks creates a healthier work environment and improves overall well-being.

Environmental Benefits of Lower VOC Emissions

Lower VOC emissions offer a range of environmental benefits. Here's how:

- Improved Air Quality: Low VOC products release fewer harmful chemicals into the air, reducing air pollution and creating a healthier environment for everyone.

- Combating Climate Change: VOCs contribute to greenhouse gases. By lowering VOC emissions, we can help mitigate climate change and its effects.

- Sustainable Practices: Choosing low VOC products is a step towards a more sustainable future. It reduces environmental impact and promotes eco-friendly practices.

By making these simple switches, we can significantly improve air quality, combat climate change, and promote a more sustainable future. Let's all do our part to create a cleaner and healthier planet.

Cost Savings from Reduced Safety Measures

In addition to the health and environmental benefits, using low VOC inks can also lead to cost savings for printing operations. With reduced emissions of harmful chemicals, there is less need for expensive safety measures such as ventilation systems and personal protective equipment. This translates into direct cost savings for businesses while promoting a safer workplace.

Qinghe Chemical's Contribution to Greener Printing

Qinghe Chemical has been at the forefront of developing environmentally friendly printing solutions, particularly in low VOC inks. Their commitment to sustainability is evident in their innovative development of water-based gravure inks, significantly reducing VOC emissions and offering a safer alternative for printers and processors.

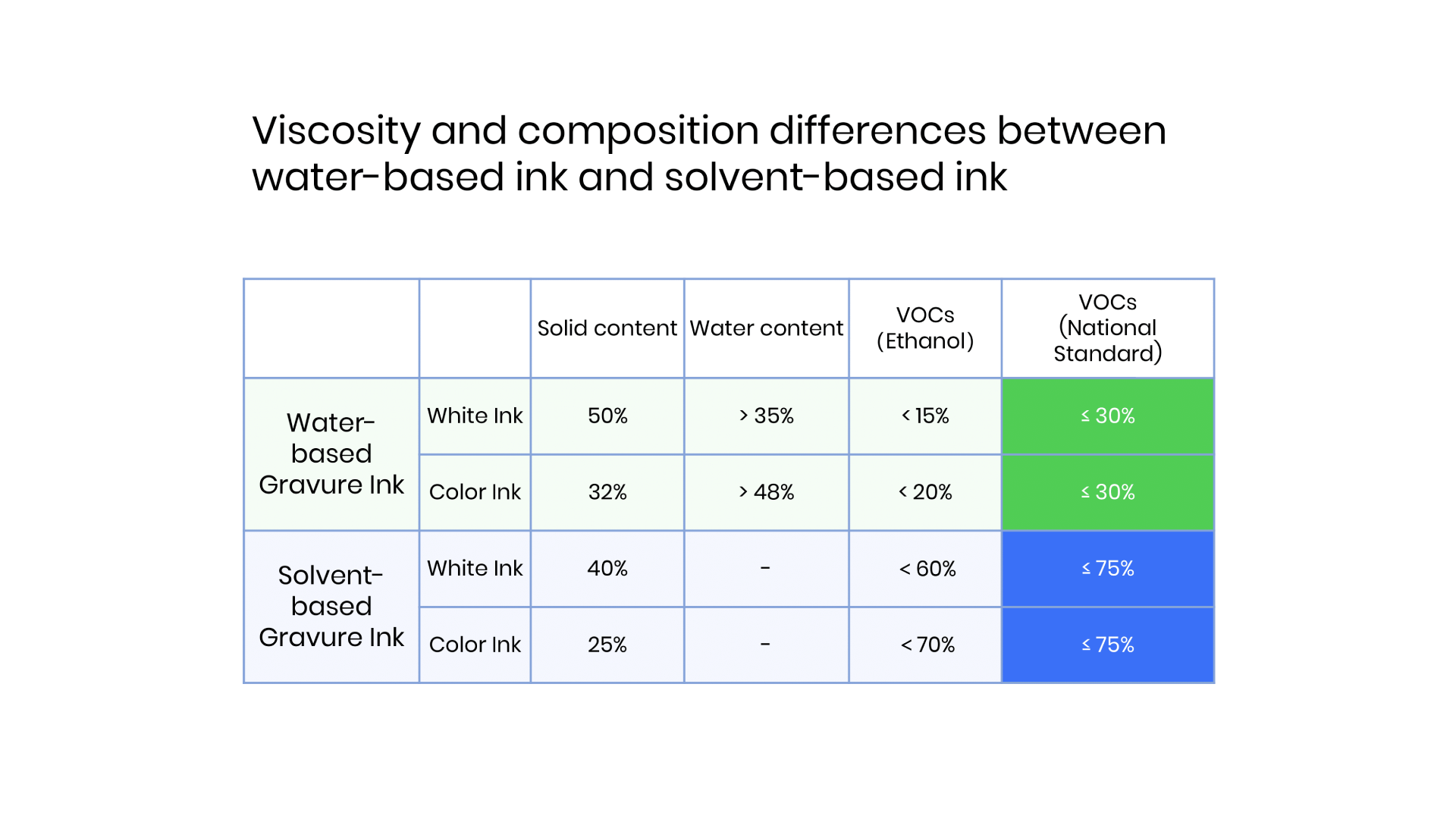

Development of Water-Based Gravure Inks

Qinghe Chemical's water-based gravure inks have revolutionized the industry by providing a low VOC solution that meets high-quality printing standards. These inks are formulated with minimal volatile organic compounds, ensuring a healthier work environment for printing professionals and reducing the environmental impact. The company's dedication to research and development has resulted in cutting-edge formulations that deliver exceptional print results without compromising on eco-friendliness.

Diverse Range of Low VOC Products

In addition to their water-based gravure inks, Qinghe Chemical offers a diverse range of low VOC products tailored to meet various printing needs. From solvent-free options to UV-curable formulations, their product line is committed to providing sustainable alternatives without sacrificing performance or quality. Printers can now choose from various low VOC options that align with their specific production requirements while minimizing environmental impact.

Applications in Flexible Food Packaging

One notable application of Qinghe Chemical's low VOC inks is in flexible food packaging, where safety and sustainability are paramount. By utilizing these eco-friendly solutions, packaging manufacturers can ensure that their products meet stringent regulatory standards while meeting consumer demand for greener packaging options. The use of low VOC inks not only reduces health risks associated with food contact materials but also contributes to a more sustainable supply chain.

Choosing Low VOC Inks for Sustainable Packaging

In today's environmentally conscious world, consumer demand for eco-friendly packaging is at an all-time high. Low VOC inks play a crucial role in meeting this demand by reducing the environmental impact of packaging printing. With their minimal volatile organic compound emissions, low VOC inks are the perfect choice for brands aligning with sustainable packaging trends.

Meeting Consumer Demand for Eco-Friendly Packaging

As consumers become more aware of the environmental impact of packaging materials, they actively seek products that are packaged using eco-friendly methods. Low VOC inks solve this growing demand by providing a greener alternative to traditional high VOC printing inks. Brands can capitalize on this trend by incorporating low VOC inks into their packaging, appealing to environmentally conscious consumers.

Regulatory Compliance with Low VOC Printing

Regulatory standards regarding VOC emissions are becoming increasingly stringent, especially in industries such as packaging printing. By choosing low VOC inks, companies can ensure compliance with these regulations while contributing to a healthier environment. This proactive approach safeguards against potential penalties and demonstrates a commitment to sustainability and responsible business practices.

The Role of Low VOC Inks in Sustainable Supply Chains

Incorporating low VOC inks into packaging printing processes contributes to the overall sustainability of supply chains. By reducing emissions and minimizing environmental impact, companies can create a more sustainable end-to-end process for their products. This approach aligns with the growing emphasis on sustainable supply chains and positions businesses as responsible stewards of the environment.

Remember that choosing low VOC ink is beneficial for your business, positively impacts the environment, and meets consumer demands for sustainable options.

The Future of Packaging Printing with Low VOC Inks

Innovations in Low VOC Ink Technology

As printing technology advances, so does the development of low VOC inks. Manufacturers are constantly improving the formulation of low VOC inks to ensure they meet the highest environmental and safety standards while maintaining excellent print quality and durability. These innovations include using renewable raw materials and advanced manufacturing processes to reduce emissions further, making low VOC inks an even more sustainable choice for packaging printing.

Collaboration for Sustainable Packaging Solutions

The future of packaging printing with low VOC inks also involves collaboration between ink manufacturers, printers, and packaging companies to create truly sustainable solutions. By working together, these stakeholders can develop packaging materials that not only use low VOC inks but also incorporate other eco-friendly elements such as recycled materials and biodegradable options. This collaborative approach ensures the entire packaging supply chain is aligned toward a greener future.

Embracing a Greener Future with Low VOC Inks

With the increasing awareness of environmental issues and the demand for sustainable products, the future of packaging printing undoubtedly lies in embracing low VOC inks. As consumers become more conscious of their purchasing decisions, they are actively seeking out products that are produced using environmentally friendly methods, including low voc inks. By shifting towards greener printing solutions, businesses can meet consumer demand and contribute to a healthier planet for future generations.

Qinghe Chemical: Your Partner for Sustainable Printing Solutions

Switching to low VOC inks is crucial for sustainable printing practices. By reducing harmful emissions and promoting a healthier work environment, low VOC inks offer many benefits for both businesses and the planet. With Qinghe Chemical leading the way in providing greener printing solutions, embracing sustainability in packaging printing is easier than ever.

Making the Switch to Low VOC Inks

When considering low VOC inks, it's important to understand their meaning and significance. Low VOC stands for volatile organic compounds, harmful chemicals commonly found in traditional printing inks. Switching to low VOC inks means opting for products with significantly reduced emissions of these toxic compounds, promoting a safer and more eco-friendly printing process.

Qinghe Chemical has been at the forefront of developing innovative low VOC ink solutions for sustainable packaging printing. With a diverse range of low VOC products, including water-based gravure inks, they have proven themselves a reliable partner for businesses looking to reduce their environmental impact without compromising print quality.

Embracing Sustainability in Packaging Printing

Embracing sustainability in packaging printing goes hand in hand with choosing low VOC inks. This decision aligns with consumer demand for eco-friendly packaging and ensures regulatory compliance with low VOC printing standards. By prioritizing sustainable supply chains and embracing greener printing solutions, businesses can positively impact the environment while meeting market demands.