Introduction

In the ever-evolving world of printing, the rise of Qinghe Chemical in water-based gravure inks has been nothing short of revolutionary. As the demand for eco-friendly solutions continues to grow, water-based inks for gravure printing have emerged as a game-changer, offering a host of benefits that are reshaping the industry. This shift towards sustainable practices is not just a trend, but a necessity in today's printing landscape.

The Rise of Qinghe Chemical in Water-Based Gravure Inks

With an increasing focus on environmental sustainability, Qinghe Chemical has positioned itself as a leader in developing innovative water-based ink solutions for gravure printing. Their commitment to providing high-quality products that minimize environmental impact has set them apart in the industry, earning them a reputation as pioneers in eco-friendly printing technology.

In addition to their environmental focus, Qinghe Chemical has also prioritized the performance and quality of their water-based gravure inks. By investing in research and development, they have been able to create inks that not only reduce environmental impact but also deliver exceptional print results. This combination of eco-friendliness and high performance has made Qinghe Chemical a top choice for printers looking to meet both sustainability goals and quality standards. As a result, they have seen a significant increase in demand for their water-based ink solutions.

Benefits of Water-Based Inks for Gravure Printing

Water-based inks are gaining traction in the gravure printing industry due to their environmental benefits and impressive performance. Here are some key advantages of switching to water-based inks:

- Vibrant Color Reproduction: Water-based inks deliver exceptional color clarity and richness, ensuring high-quality visuals on your printed materials.

- Excellent Adhesion: These inks adhere well to various substrates, providing a durable and long-lasting print on various surfaces.

- Minimal Odor: Unlike solvent-based inks, water-based inks produce minimal odor, creating a more pleasant working environment for printers.

- Fast Drying Times: Water-based inks boast faster drying times, improving printing efficiency and throughput.

- Low VOC Emissions: These inks are formulated with minimal volatile organic compounds (VOCs), significantly reducing air pollution and promoting a healthier workplace.

- Recyclable and Biodegradable: Water-based inks are easily recyclable and biodegradable, minimizing waste and environmental impact.

In conclusion, choosing water-based inks for gravure printing presents a win-win situation. Businesses can achieve exceptional print quality while demonstrating their commitment to sustainability, aligning with the growing eco-conscious movement and attracting environmentally responsible consumers.

Eco-Friendly Solutions in Printing Industry

As the world becomes increasingly aware of the environmental impact of traditional printing methods, there is a growing demand for eco-friendly alternatives. Water-based inks for gravure printing provide a sustainable solution by reducing harmful emissions and waste, aligning with the global push towards greener practices and responsible manufacturing. Water-based inks are non-toxic and do not contain volatile organic compounds (VOCs), making them safer for workers and consumers. This environmentally friendly option also offers vibrant color reproduction and excellent adhesion to various substrates, ensuring high-quality results without compromising on performance.

Understanding Water Based Ink for Gravure Printing

Water-based ink for gravure printing is a modern alternative to traditional solvent-based inks. Gravure printing is a high-quality, high-speed printing process that uses a cylindrical printing plate to transfer the image onto the substrate. This method is widely used for packaging, labels, and magazines because it produces sharp, detailed images with vibrant colors.

What is Gravure Printing?

Gravure printing, or intaglio printing, involves etching the image onto a metal plate, typically made of copper or chrome. The recessed areas hold the ink while the raised surfaces are wiped clean. As the substrate passes between the plate and a rubber-coated impression roller, the ink is transferred onto it. This process allows for consistent and precise reproduction of images on various materials.

Gravure printing is particularly well-suited for high-volume printing jobs due to its ability to reproduce images with fine detail and color accuracy consistently. This makes it a popular choice for packaging, magazines, and catalogs where image quality is paramount. Additionally, using metal plates in gravure printing allows for a longer lifespan than other printing methods, resulting in cost savings over time. The process also offers versatility regarding the materials it can print on, including paper, plastic, and metal, making it a go-to choice for various industries.

Advantages of Water Based Ink

Water-based inks are becoming increasingly popular in printing due to their environmental and health benefits. Here are some of the key advantages of using water-based inks:

- Safer for Workers and the Environment: Water-based inks are non-toxic and emit fewer volatile organic compounds (VOCs) compared to solvent-based inks. This reduces health risks for workers who come into contact with the ink and minimizes the environmental impact of the printing process.

- Fast Drying: Water-based inks dry quickly, which can significantly improve printing efficiency and throughput. This is especially beneficial for high-volume printing operations.

- Vibrant Colors and Excellent Adhesion: Water-based inks produce vibrant colors that adhere well to various substrates, including paper, fabric, and plastic. This ensures high-quality prints that are durable and long-lasting.

In conclusion, water-based inks offer a compelling alternative to traditional solvent-based inks. They provide a safer work environment, reduce environmental impact, and deliver excellent print quality, making them a win-win for printers and the environment.

Is Water Based Ink Waterproof?

Yes, water-based inks can be waterproof depending on their formulation and application method. By adding specific additives or coatings during or after printing, water-based ink can achieve varying degrees of water resistance suitable for different end-uses, such as food packaging or outdoor signage.

Stay tuned for more insights into water based inks for screen printing and their applications!

Types of Inks Used in Gravure Printing

Solvent-Based vs Water-Based Inks

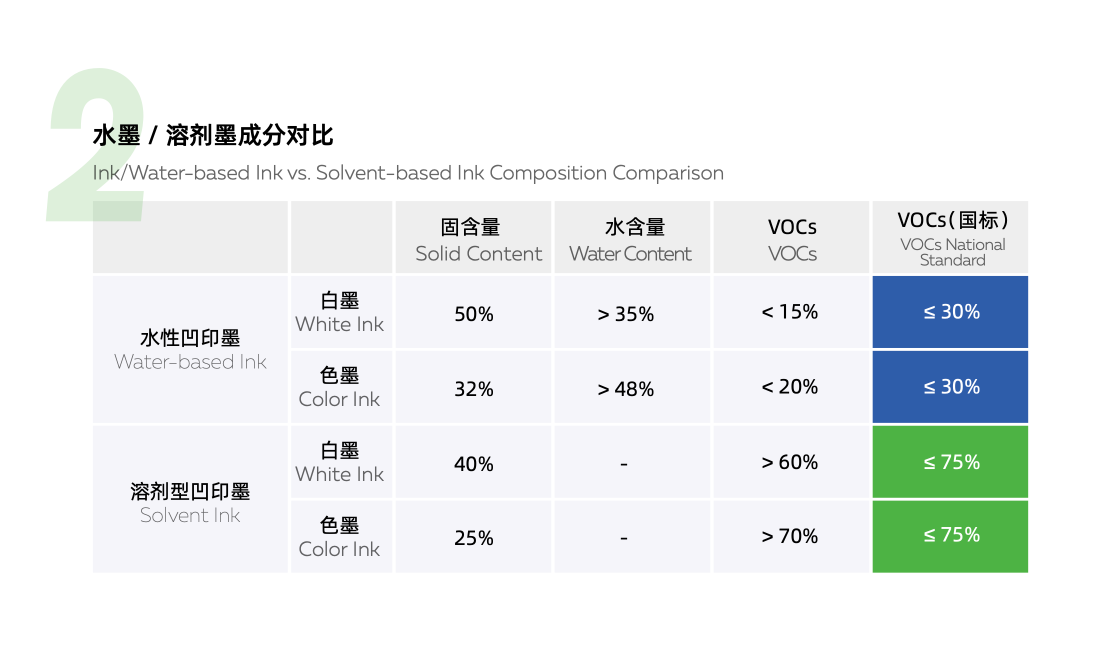

The choice of ink is crucial when it comes to gravure printing. Solvent-based inks contain volatile organic compounds (VOCs), which can harm the environment and human health. On the other hand, water-based inks are eco-friendly and offer a safer alternative for printing. They are also known for their fast drying time and vibrant color reproduction.

Furthermore, water-based inks are easier to clean than solvent-based inks, making them a more convenient option for printers. This saves time and effort and reduces the use of harsh chemicals for cleaning. Additionally, water-based inks have a lower odor than solvent-based inks, creating a more pleasant working environment for printing professionals.

Water Based Inks for Screen Printing

Water-based inks are not only suitable for gravure printing but also for screen printing. They provide excellent adhesion to various substrates, making them ideal for various applications such as posters, banners, and packaging materials. Their ability to produce high-quality prints with minimal impact on the environment makes them a popular choice among printers.

Water Based Screen Printing Ink for Fabric

In addition to paper-based materials, water-based inks are also used for fabric screen printing. These inks offer excellent wash fastness and color retention on textiles, making them perfect for creating durable and vibrant designs on clothing, accessories, and home textiles.

Furthermore, water-based inks are known for their ease of use and versatility, allowing for a wide range of effects and techniques on fabric. Whether it's creating intricate patterns or bold, solid colors, these inks provide the flexibility needed to bring any design to life. This makes them a favorite among designers and artists looking to push the boundaries of traditional fabric printing.

The Environmental Impact

Water-based inks for gravure printing have gained traction due to their significant reduction of VOC emissions, making them a more environmentally friendly option than solvent-based inks. With water-based inks, releasing volatile organic compounds (VOCs) into the atmosphere is greatly minimized, contributing to cleaner air and a healthier work environment for printing professionals.

Reduction of VOC Emissions

The use of water-based inks for gravure printing significantly reduces VOC emissions, harmful pollutants known to contribute to air pollution and health issues. By opting for water-based inks, printers can mitigate their environmental impact and comply with stricter emissions regulations, demonstrating a commitment to sustainability and responsible business practices.

By reducing VOC emissions through water-based inks, printers can also improve the indoor air quality of their facilities, creating a healthier work environment for their employees. This can lead to increased productivity, employee satisfaction, and lower healthcare costs associated with poor air quality. Additionally, by embracing sustainable practices such as water-based inks, printers can enhance their brand image and appeal to environmentally-conscious consumers who prioritize eco-friendly products.

Sustainable Packaging Solutions

As the demand for eco-friendly packaging continues to grow, water-based inks offer sustainable solutions for gravure printing on various packaging materials. From paperboard cartons to flexible packaging films, water-based inks provide vibrant colors and excellent adhesion while meeting the requirements for recyclability and compostability, aligning with the shift towards sustainable packaging options.

Contribution to Green Initiatives

Water-based inks for gravure printing play a crucial role in supporting green initiatives across industries by promoting sustainable production processes and reducing the environmental footprint of printed materials. As companies strive to enhance their sustainability efforts, adopting water-based inks contributes to a more eco-conscious approach that resonates with environmentally conscious consumers.

Remember that using water based ink for gravure printing not only reduces VOC emissions but also offers sustainable solutions for packaging materials while contributing to green initiatives across industries.

The Role of Qinghe Chemical

Innovations in Water-Based Inks

Qinghe Chemical has been developing innovative water-based inks for gravure printing, revolutionizing the industry with their cutting-edge formulations. These inks offer superior print quality, vibrant colors, and excellent adhesion to various substrates, making them the top choice for environmentally conscious printers.

Commitment to Sustainability

With a strong commitment to sustainability, Qinghe Chemical has focused on creating water-based inks that minimize environmental impact without compromising performance. By replacing traditional solvent-based inks with eco-friendly alternatives, they have set a new standard for responsible printing practices. They are leading the way towards a greener future for the industry.

Environmental Benefits of Using Qinghe's Products

Using Qinghe's water-based inks for gravure printing reduces VOC emissions and contributes to sustainable packaging solutions by eliminating harmful chemicals from the production process. This aligns with the growing demand for eco-friendly printing solutions and positions Qinghe Chemical as an industry leader in providing environmentally responsible products.

Now that we have discussed the role of Qinghe Chemical in driving innovation and sustainability within the printing industry through their water-based inks, let's explore how these advancements are shaping future trends and applications.

Future Trends and Applications

Demand for Eco-Friendly Printing Solutions

The increasing awareness of environmental issues has led to a growing demand for eco-friendly printing solutions. Water-based inks for gravure printing offer a sustainable alternative to traditional solvent-based inks, making them highly sought after by environmentally conscious businesses and consumers alike.

Market Shift Towards Water-Based Inks

As more industries prioritize sustainability, there is a noticeable shift towards water-based inks for various printing applications. This trend is driven by the need to reduce harmful emissions and minimize the environmental impact of printing processes. With technological advancements, water-based inks are becoming increasingly popular across different sectors.

Potential for Expansion into New Industries

The versatility of water-based inks opens up opportunities for expansion into new industries beyond traditional printing applications. From packaging to textiles, the demand for environmentally friendly ink solutions continues to grow. This presents an exciting prospect for the widespread adoption of water-based inks across diverse sectors.

Qinghe Chemical: Leading the Way in Eco-Friendly Solutions

Water-based inks for gravure printing have revolutionized the industry, offering sustainable and eco-friendly solutions for various applications. With their low VOC emissions and impressive print quality, water-based inks are becoming the go-to choice for environmentally conscious businesses.

Sustainable Printing Practices with Water-Based Inks

The shift towards water-based inks for gravure printing signifies a commitment to sustainable practices in the printing industry. By reducing harmful emissions and promoting eco-friendly alternatives, businesses can contribute to a cleaner and greener future while still delivering high-quality printed materials.

Qinghe Chemical has been at the forefront of developing innovative water-based inks for gravure printing. Their dedication to sustainability and environmental responsibility has set them apart as leaders in providing eco-friendly solutions that meet the needs of modern businesses.

Embracing the Future of Gravure Printing with Water-Based Inks

Water-based inks are poised to become even more prevalent in the industry as demand grows for eco-friendly printing solutions. Embracing this future means adopting sustainable practices that benefit businesses and the environment, making it a win-win situation for all involved.