Introduction

Gravure printing is a widely used technique in the packaging industry, known for its high-quality, detailed images and vibrant colors. At the heart of this printing process lies gravure ink, a specialized coating that ensures flawless results on various substrates. As environmental concerns continue to grow, the demand for sustainable solutions has led to the rise of water-based gravure ink as a game-changing alternative.

What is Gravure Printing Ink?

Gravure ink is specifically formulated for gravure printing, transferring an image onto a substrate using an engraved cylinder. This method allows for precise and consistent ink application, making it ideal for high-volume production with intricate designs. In recent years, there has been a growing demand for eco-friendly printing solutions, leading to the development of water-based gravure inks. These inks offer a more sustainable alternative to traditional solvent-based options, reducing environmental impact without compromising print quality.

The Eco-friendly Solution: Water-Based Gravure Ink

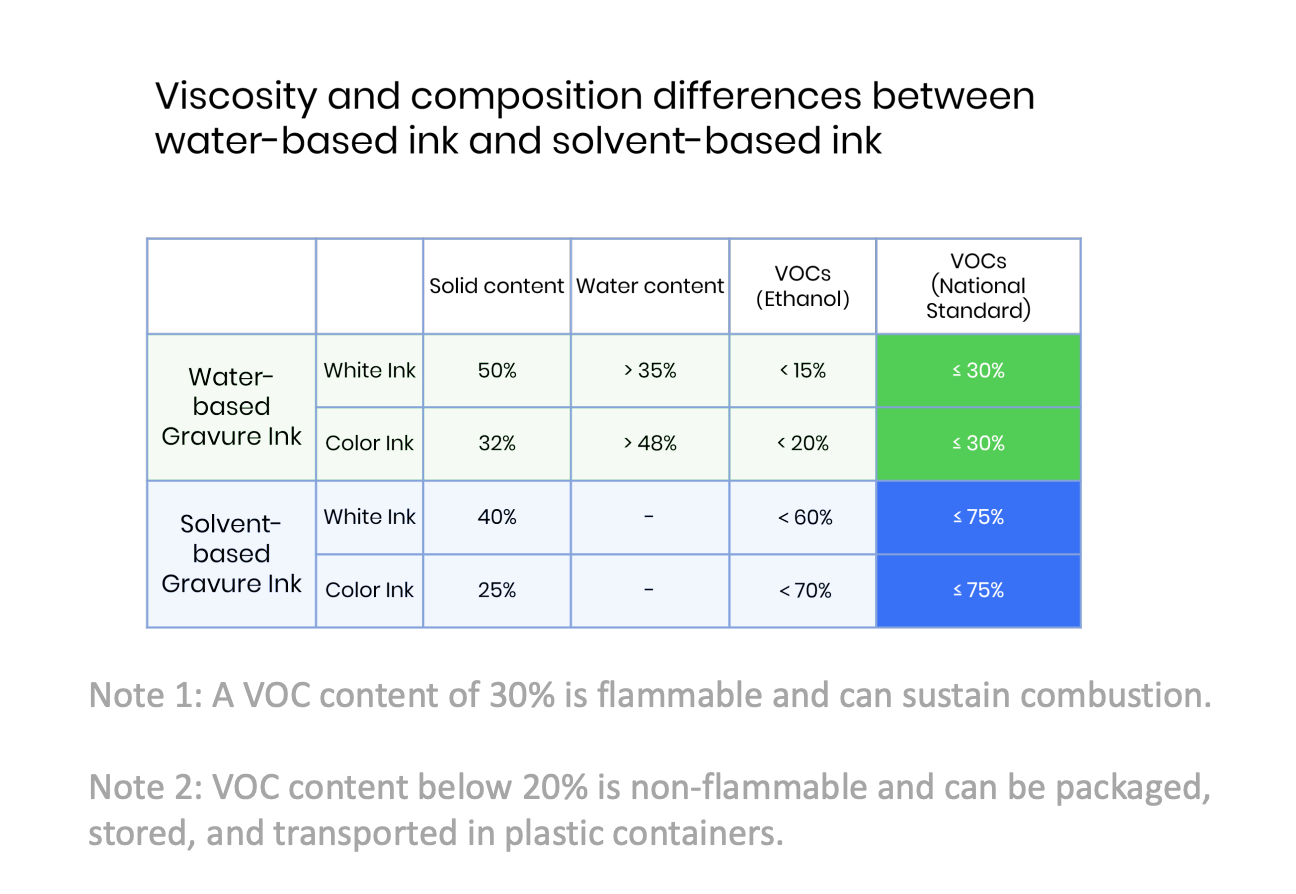

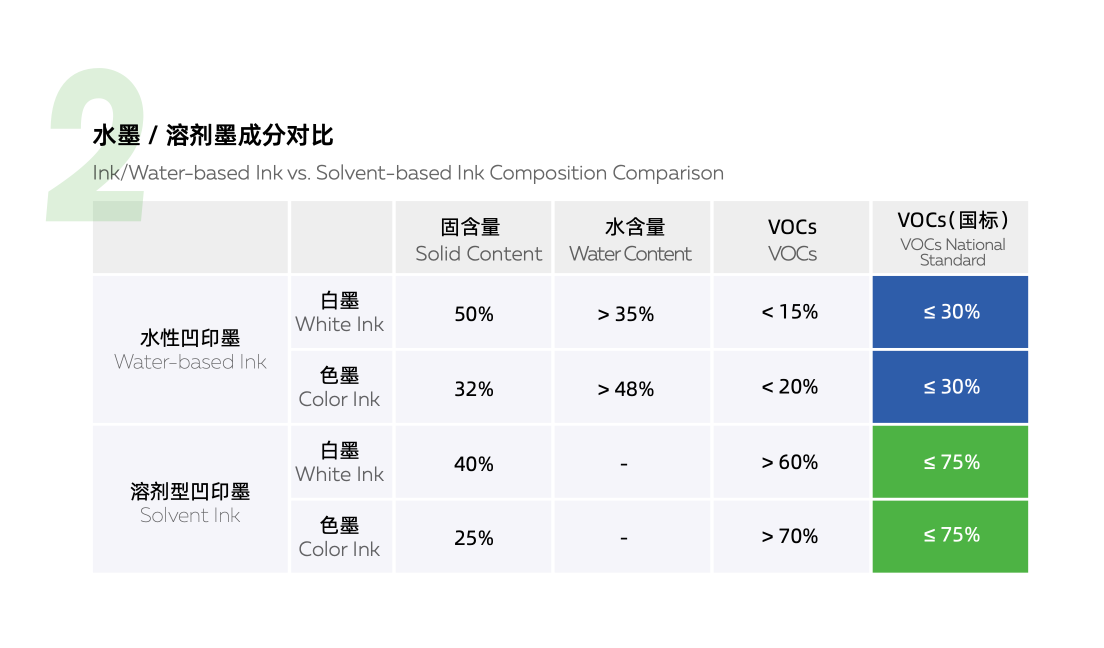

Water-based gravure ink has emerged as an eco-friendly alternative to traditional solvent-based inks. By replacing harmful solvents with water as the main carrier, this innovative solution significantly reduces volatile organic compound (VOC) emissions and minimizes environmental impact without compromising print quality.

Qinghe Chemical: Leading the Green Printing Revolution

Qinghe Chemical has emerged as a leader in sustainable printing, pioneering advanced formulations of water-based gravure ink. Committed to environmental responsibility and innovation, the company is at the forefront of providing eco-friendly solutions for the packaging industry.

Let’s explore the evolution of gravure ink and its role in sustainable printing practices. Water-based gravure ink offers several key advantages:

- Reduced environmental impact: Lower VOC emissions and minimal waste.

- Improved worker safety: Safer working conditions due to reduced solvent exposure.

- Enhanced print quality: Modern formulations deliver exceptional results.

- Cost-effective: Potential savings through reduced waste and energy consumption.

By adopting water-based gravure ink, businesses can contribute to a greener future while maintaining high-quality print output.

The Evolution of Gravure Ink

From Solvent-based to Water-based Solutions

In the past, gravure ink was primarily solvent-based, leading to harmful VOC emissions and posing health risks to workers. However, with the advancement of technology, water-based solutions have emerged as a safer and more environmentally friendly alternative for gravure printing. This shift has significantly reduced the environmental impact of printing processes while improving work safety for employees.

The shift from solvent-based to water-based solutions has also brought about significant improvements in the quality of gravure printing. Water-based inks have been shown to provide better color consistency, improved print resolution, and enhanced overall print quality compared to their solvent-based counterparts. This advancement has made gravure printing safer and more eco-friendly and has also elevated the output standard for businesses and industries utilizing this printing method.

Advantages of Polyurethane Resin for Gravure Ink

Polyurethane resin has become a game-changer in gravure ink due to its exceptional adhesion properties and durability. This innovative material allows for vibrant and long-lasting prints while offering excellent resistance to abrasion and chemicals. As a result, polyurethane resin has become an essential component in formulating high-quality water-based gravure inks.

Polyurethane resin's versatility makes it an ideal choice for gravure ink formulation, as it can be easily customized to meet specific printing requirements. This adaptability allows for creating inks with varying flexibility, viscosity, and drying time, catering to a wide range of substrates and printing conditions. Using polyurethane resin, ink manufacturers can develop tailored solutions that deliver superior performance on different materials, ensuring consistent and high-quality results across various applications.

Water-Based Ink for Gravure Printing: A Game Changer

Introducing water-based ink for gravure printing has revolutionized the industry by providing a sustainable and eco-friendly solution without compromising print quality. Unlike traditional solvent-based inks, water-based options offer faster drying times, improved color consistency, and enhanced print clarity. This shift towards water-based ink has not only reduced environmental impact but also elevated the overall printing standards.

The transition to water-based ink for gravure printing has also reduced volatile organic compound (VOC) emissions, further contributing to a healthier and cleaner environment. By eliminating harmful chemicals present in solvent-based inks, water-based options have significantly minimized air pollution and potential health risks for workers in the printing industry. This shift has not only improved the working conditions for employees but has also positioned companies as responsible stewards of the environment.

Stay tuned as we delve into the environmental benefits of water-based gravure ink in our next section!

Environmental Benefits of Water-Based Gravure Ink

Water-based gravure ink offers significant environmental benefits, making it a sustainable choice for the printing industry.

Reduced VOC Emissions

Water-based gravure inks offer a sustainable alternative to traditional solvent-based inks. Businesses can significantly reduce their environmental impact and improve workplace safety by switching to water-based inks.

Water-based gravure inks provide numerous benefits:

- Reduced VOC emissions: Help to improve air quality and reduce health risks associated with solvent exposure.

- Cost savings: Eliminate the need for expensive ventilation systems and safety equipment.

- Improved workplace health: Create a healthier work environment for employees by reducing exposure to harmful fumes.

Transitioning to water-based gravure inks is environmentally responsible and financially beneficial. Businesses can contribute to a cleaner planet by making this switch while improving their bottom line.

Elimination of Costly Safety Measures

With solvent-based inks, costly safety measures such as ventilation systems and protective gear are required to mitigate the health risks associated with VOC exposure. Water-based gravure ink eliminates the need for these safety measures, saving businesses time and money.

Sustainable Packaging Solutions

Water-based gravure ink enables the production of sustainable packaging solutions by reducing environmental impact. This eco-friendly ink option aligns with consumer demand for environmentally responsible packaging materials, offering a competitive edge in today's market.

Water-based gravure ink reduces environmental impact and offers cost efficiency for packaging manufacturers. This eco-friendly ink option allows companies to save on production costs and minimize waste, ultimately contributing to a more sustainable and profitable operation. Additionally, water-based gravure ink promotes work safety by eliminating exposure to harmful chemicals commonly found in traditional solvent-based inks.

Cost Efficiency and Work Safety

Lower Production Costs

Water-based gravure ink offers significant cost savings in the printing process. Reduced solvent usage and lower energy consumption minimize production costs, leading to more affordable printing solutions for businesses. Water-based gravure ink also eliminates the need for expensive ventilation systems, contributing to cost efficiency.

In addition to cost savings, water-based gravure ink also offers workers improved health and safety benefits. Reduced solvent usage exposes employees to fewer harmful chemicals, leading to a healthier work environment. This can decrease absenteeism and improve worker productivity, contributing to overall business cost efficiency. Furthermore, eliminating expensive ventilation systems saves money and reduces potential hazards related to air quality in the workplace.

Health and Safety Benefits for Workers

The shift to water-based gravure ink promotes a safer work environment for printing professionals. By eliminating harmful volatile organic compounds (VOCs) in solvent-based inks, workers are less exposed to hazardous chemicals that pose serious health risks. This not only ensures the well-being of employees but also reduces potential liability for companies.

Streamlined Transportation and Storage

Water-based gravure ink simplifies logistics and storage requirements due to its non-flammable nature. It reduces transportation costs and safety hazards associated with flammable solvents used in traditional gravure inks. Its stable composition allows for easier handling and storage, providing a more efficient workflow for printing facilities.

In addition to simplifying logistics and reducing transportation costs, water-based gravure ink also offers environmental benefits. Eliminating the need for flammable solvents reduces the risk of air and water pollution, making it a more sustainable option for printing facilities. This eco-friendly aspect aligns with corporate social responsibility initiatives and appeals to environmentally conscious consumers, providing a competitive edge in the market.

Applications of Water-Based Gravure Ink

Water-based gravure ink has revolutionized the printing industry with its versatility and eco-friendly nature. One of its primary applications is in flexible food packaging, where the ink provides vibrant colors and excellent adhesion to various substrates. This makes it ideal for ensuring food safety and quality while reducing environmental impact.

Flexible Food Packaging

Water-based gravure ink is perfect for flexible food packaging due to its low migration properties, making direct contact with food products safe. Its fast drying time and high printability ensure efficient production processes, while its low VOC content supports sustainable packaging solutions that meet strict regulatory requirements.

Furthermore, water-based gravure ink offers excellent adhesion to various flexible packaging materials, including plastic films and foils. This versatility allows for creating eye-catching designs and vibrant colors that enhance product visibility on store shelves, helping to attract consumers and drive sales. Additionally, the ink's resistance to abrasion and scuffing ensures that packaging maintains its visual appeal throughout the supply chain, from production to point of sale.

In-printing and Compounding

Water-based gravure ink is a versatile material with many applications beyond food packaging.

- In-printing and compounding: This ink is commonly used to create intricate designs on various substrates.

- Adhesion: Its ability to adhere to paper, film, and foil makes it ideal for eye-catching labels and stickers.

- Versatility: Compatible with multiple printing processes, it delivers high-precision, vibrant prints.

- Industry applications: This ink's ability to enhance product presentation benefits the cosmetics, pharmaceuticals, and consumer goods sectors greatly.

Combining these factors makes water-based gravure ink an essential tool for achieving visually striking and high-quality printed materials.

Wide Range of Printing Applications

Furthermore, water-based gravure ink offers a wide range of printing applications beyond packaging materials. Due to its exceptional print quality and environmental benefits, it is commonly used in decorative laminates, wallpapers, gift wraps, and even automotive interior components.

In addition to its use in decorative laminates, wallpapers, gift wraps, and automotive interior components, water-based gravure ink has also found its way into producing high-quality magazines and catalogs. Its ability to produce sharp images and vibrant colors makes it a popular choice for publishers looking to make a strong visual impact on their readers. The environmental benefits of water-based gravure ink also align with the sustainability goals of many printing companies, further contributing to its widespread adoption in the industry.

Qinghe Chemical: Pioneering Eco-friendly Gravure Inks

Water-based gravure ink is the future of eco-friendly printing, offering a sustainable solution for the gravure printing industry. With reduced VOC emissions and lower production costs, it provides a cost-effective and environmentally conscious alternative to traditional solvent-based inks. As the demand for green printing solutions grows, water-based gravure ink will play a key role in environmental conservation efforts.

Sustainable Future with Water-Based Gravure Ink

Water-based gravure ink is a sustainable and efficient solution for the printing industry.

By switching to water-based gravure ink, companies can enjoy several key benefits:

- Reduced environmental impact: Lower emissions and a smaller carbon footprint.

- Improved workplace safety: Water-based inks are generally less hazardous than solvent-based alternatives.

- Cost savings: Potential reductions in energy consumption and waste management.

- Enhanced brand reputation: Demonstrate a commitment to sustainability and corporate social responsibility.

Embracing water-based gravure ink is a strategic move that aligns with growing consumer demand for eco-friendly products and services.

Green Printing Solutions for Environmental Conservation

Adopting water-based gravure ink represents a significant step towards environmental conservation in the printing industry. With its reduced environmental impact and cost efficiency, this green solution aligns with global efforts to reduce carbon footprints and promote sustainable practices.

Qinghe Chemical is at the forefront of the green printing revolution, developing eco-friendly gravure inks. Its commitment to sustainability and innovation has positioned it as a trailblazer in providing water-based solutions that meet the highest quality standards and environmental responsibility.

Qinghe Chemical's eco-friendly gravure inks are environmentally responsible and deliver exceptional performance on a wide range of substrates. Their dedication to research and development has resulted in inks that offer vibrant colors, excellent adhesion, and fast drying times, making them the top choice for printers looking to reduce their environmental impact without sacrificing quality. By choosing Qinghe Chemical's gravure inks, printers can demonstrate their commitment to sustainability while achieving outstanding results.