Introduction

In the fast-paced world of packaging, the evolution of flexible packaging inks has been nothing short of remarkable. From traditional solvent-based inks to the revolutionary water-based solutions, the industry has seen a significant shift towards more sustainable and environmentally friendly options. As a result, companies like Qinghe Chemical have been at the forefront of this printing revolution, offering cutting-edge water-based inks for labels and flexible packaging that are not only high-quality but also eco-friendly. With a growing focus on reducing the environmental impact of packaging inks for food and plastic films, it's clear that the future lies in embracing innovative solutions that prioritize sustainability without compromising on performance.

The Evolution of Flexible Packaging Inks

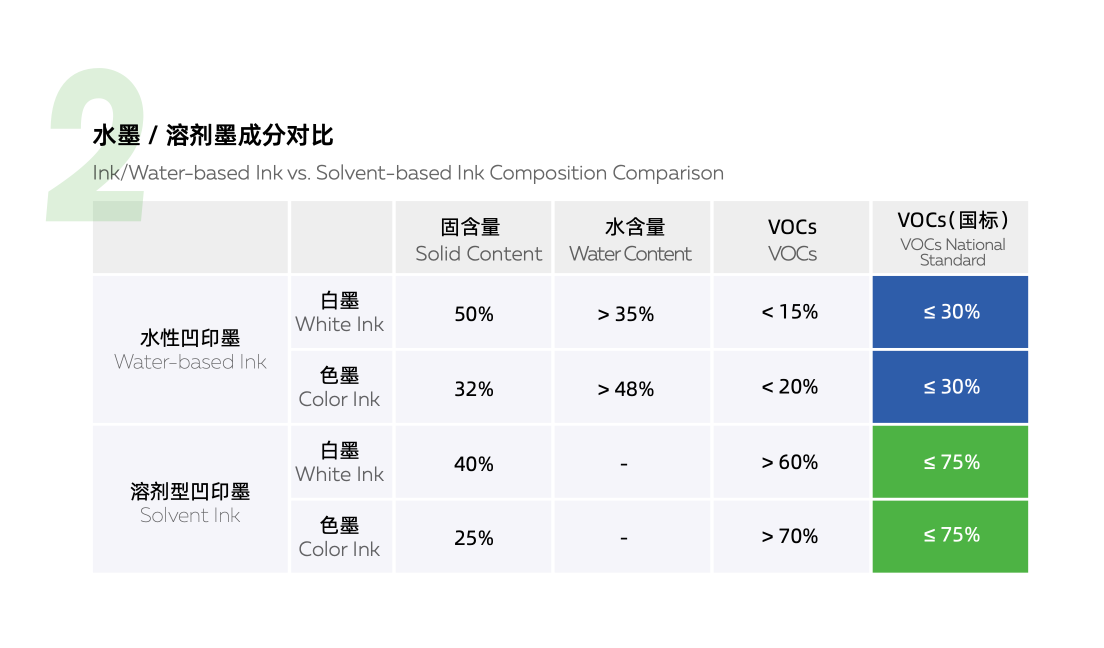

The evolution of flexible packaging inks has been driven by the need for more sustainable and eco-friendly solutions. Traditional solvent-based inks posed significant environmental concerns due to their high VOC emissions and hazardous waste disposal requirements. This led to a shift towards water-based inks that offer lower VOC emissions, reduced environmental impact, and improved safety for workers.

Qinghe Chemical: Revolutionizing Printing with Water-Based Inks

Qinghe Chemical has been at the forefront of this printing revolution, offering a wide range of water-based inks for labels and flexible packaging. Their innovative solutions have not only revolutionized the industry but have also set new standards for quality, performance, and sustainability. By prioritizing water-based ink for flexible packaging applications, Qinghe Chemical is leading the way towards greener printing practices that benefit both businesses and the environment.

The Environmental Impact of Flexible Packaging Printing Inks

The environmental impact of traditional packaging inks for food and plastic films cannot be overlooked. With increasing concerns over pollution and waste generation, there is a growing demand for sustainable alternatives that minimize harm to the environment. Water-based inks offer a promising solution by significantly reducing VOC emissions and hazardous waste disposal requirements, making them an ideal choice for environmentally conscious businesses looking to make a positive impact.

Understanding Flexible Packaging Printing

Flexible packaging inks play a crucial role in the branding and protection of products. These inks are specifically designed to adhere to a variety of substrates, including plastic films and other packaging materials, ensuring that the printed designs remain vibrant and durable throughout the product's lifecycle.

The Role of Inks in Flexible Packaging

Inks for labels and flexible packaging serve multiple purposes, such as providing essential information about the product, enhancing its visual appeal, and ensuring that it stands out on crowded store shelves. Additionally, these inks must be able to withstand various environmental conditions and maintain their integrity during transportation and storage.

Key Considerations for Choosing the Right Printing Ink

When selecting flexible packaging printing ink for plastic films or food packaging, it is essential to consider factors such as adhesion properties, color vibrancy, resistance to abrasion or chemicals, and compliance with food safety regulations. This ensures that the chosen ink will meet the specific requirements of the packaging application.

Innovations in Flexible Packaging Printing Technology

Recent advancements in printing technology have led to the development of high-performance inks that offer improved print quality, faster drying times, and enhanced sustainability features. These innovations enable manufacturers to achieve greater efficiency while meeting evolving consumer demands for eco-friendly packaging solutions.

The Benefits of Using Water-Based Inks

Water-based inks offer a range of benefits for ink for flexible packaging applications. Firstly, they significantly reduce the environmental impact of printing, as they contain fewer harmful chemicals and solvents compared to traditional inks. This makes them an ideal choice for companies looking to minimize their carbon footprint and contribute to sustainable packaging solutions.

Reducing Environmental Impact with Water-Based Inks

By choosing water-based inks for labels and flexible packaging, companies can actively reduce their environmental impact. These inks are formulated with fewer volatile organic compounds (VOCs) and hazardous air pollutants, making them a more eco-friendly option for printing on plastic films and food packaging materials. This not only helps to protect the environment but also ensures compliance with stringent environmental regulations.

Ensuring Safety and Health with Low VOC Emissions

In addition to their environmental benefits, water-based inks prioritize safety and health by emitting low levels of VOCs during the printing process. This is particularly important when it comes to packaging inks for food, as it minimizes the risk of chemical contamination that could compromise the safety of consumable products. Choosing water-based solutions is therefore a proactive step towards ensuring the well-being of consumers.

Cost-Effectiveness of Water-Based Solutions

Contrary to popular belief, water-based inks also offer cost-effectiveness without sacrificing quality or performance. While they may have a slightly higher initial cost compared to solvent-based inks, they require less maintenance and cleanup due to their non-toxic nature. This ultimately leads to reduced downtime and increased efficiency on the production line, making them a smart investment for businesses looking to streamline their operations.

Qinghe Chemical's Range of Water-Based Inks

Qinghe Chemical is a leading provider of high-quality ink for flexible packaging applications. Their water-based inks are specially formulated to meet the rigorous demands of printing on plastic films and other flexible packaging materials. With a focus on vibrant colors and excellent adhesion, Qinghe Chemical's inks ensure that labels and packaging stand out on the shelf.

High-Quality Ink for Flexible Packaging Applications

The ink for flexible packaging from Qinghe Chemical is designed to deliver exceptional performance, even in challenging printing environments. Whether it's for food packaging or industrial applications, their inks offer superior durability and resistance to abrasion, ensuring that the printed designs remain intact throughout the product's lifecycle. This makes them an ideal choice for brands looking to create eye-catching and long-lasting packaging solutions.

Customizable Solutions for Various Printing Needs

In addition to their standard range of inks for labels and flexible packaging, Qinghe Chemical also offers customizable solutions to meet specific printing requirements. From specialized color matching to tailored viscosity levels, their team works closely with clients to develop inks that align perfectly with their unique branding and design needs. This level of customization ensures that every print job is executed with precision and consistency.

Sustainable Packaging Solutions with Qinghe Chemical Inks

As the industry continues to prioritize sustainable practices, Qinghe Chemical remains committed to providing eco-friendly options for flexible packaging printing ink for plastic films. Their water-based inks are formulated with low VOC emissions, reducing environmental impact without compromising on print quality. By choosing Qinghe Chemical's inks, brands can contribute to a greener future while still achieving stunning results on their packaging materials.

Advancements in Flexible Packaging Printing

Flexible packaging printing has seen significant advancements in recent years, with the future of printing technology looking brighter than ever. As consumer demands for sustainable and visually appealing packaging continue to rise, the industry is embracing innovative solutions to meet these needs.

The Future of Printing Technology for Flexible Packaging

Cutting-edge digital printing technology is revolutionizing the way ink for flexible packaging is applied to plastic films and labels. This new era of printing allows for greater customization, vibrant colors, and intricate designs, all while maintaining high-quality and cost-effectiveness.

Meeting Regulatory Standards with Innovative Printing Solutions

As regulations around food safety and environmental impact become more stringent, ink suppliers are developing innovative solutions to ensure compliance. These advancements in ink formulation and application techniques are crucial for meeting regulatory standards without compromising on print quality or safety.

Adapting to Market Demands with Cutting-Edge Printing Technology

With the rise of e-commerce and direct-to-consumer brands, the demand for flexible packaging printing ink for plastic films has never been higher. Printers are adapting by investing in state-of-the-art machinery that can handle various substrates while delivering consistent and high-quality prints to meet market demands.

Ensuring Quality and Safety in Flexible Packaging

Quality Assurance and Testing of Printing Inks

When it comes to ink for flexible packaging, quality assurance is paramount. Ink manufacturers like Qinghe Chemical invest in rigorous testing to ensure their inks meet industry standards for adhesion, color consistency, and durability on various substrates. This commitment to quality guarantees that the inks perform reliably in real-world packaging applications.

Safety Standards for Flexible Packaging Printing

Inks for labels and flexible packaging must comply with stringent safety regulations to ensure they are safe for use with food products. Qinghe Chemical's water-based inks are formulated with low VOC emissions and non-toxic components, meeting the highest safety standards for food packaging. This emphasis on safety gives brands and consumers peace of mind when using flexible packaging solutions.

The Importance of Choosing Reliable Ink Suppliers

Selecting a trustworthy ink supplier is crucial for ensuring the quality and safety of flexible packaging printing inks. Qinghe Chemical's reputation as a leading provider of sustainable packaging inks speaks volumes about their commitment to excellence. By choosing a reliable supplier, brands can confidently deliver high-quality, safe, and environmentally friendly packaging solutions to their customers.

Conclusion

In conclusion, making informed decisions for sustainable packaging solutions is crucial in today's environmentally conscious world. By choosing water-based inks for labels and flexible packaging, businesses can significantly reduce their environmental impact while ensuring the safety and health of consumers and workers. Qinghe Chemical's commitment to leading the way to greener printing with their range of high-quality and customizable inks for flexible packaging is a testament to their dedication to sustainability. Embracing innovation for a sustainable future in flexible packaging is not just a trend, but a necessity for the preservation of our planet.

Making Informed Decisions for Sustainable Packaging Solutions

When it comes to ink for flexible packaging, making informed decisions that prioritize sustainability is key. By understanding the environmental impact of different printing inks for labels and flexible packaging, businesses can choose solutions that minimize harm to the planet while meeting their printing needs effectively. With advancements in technology and the availability of water-based inks for food packaging, it's easier than ever to make sustainable choices without compromising on quality or performance.

Qinghe Chemical: Leading the Way to Greener Printing

Qinghe Chemical has established itself as a leader in providing innovative ink solutions for flexible packaging printing ink for plastic films that prioritize environmental responsibility. Their range of water-based inks for labels and flexible packaging not only offers high-quality results but also reduces VOC emissions and promotes safer working environments. By partnering with Qinghe Chemical, businesses can demonstrate their commitment to sustainability while benefiting from cutting-edge printing technology.

Embracing Innovation for a Sustainable Future in Flexible Packaging

Embracing innovation means staying ahead of regulatory standards and market demands when it comes to ink for flexible packaging. With continuous advancements in flexible packaging printing technology, businesses have the opportunity to adapt to changing consumer preferences while reducing their environmental footprint. By investing in sustainable packaging inks for food and other products, companies can contribute to a greener future while meeting the growing demand for eco-friendly solutions.