Introduction

In the world of heat shrink packaging, innovation is key to staying ahead in the game. One such groundbreaking innovation is water-based ink, revolutionizing how we approach shrink wrap solutions. With its eco-friendly nature and impressive print quality, water-based ink has become a game-changer in the industry, impacting packaging and equipment.

The Advantages of Water-Based Ink in Heat Shrink Packaging

Heat shrink packaging offers a convenient and secure way to wrap products. But did you know the type of ink used for printing on this packaging can make a big difference? Water-based inks are becoming increasingly popular for heat shrink applications, and for good reason. Here are some of the key advantages they offer:

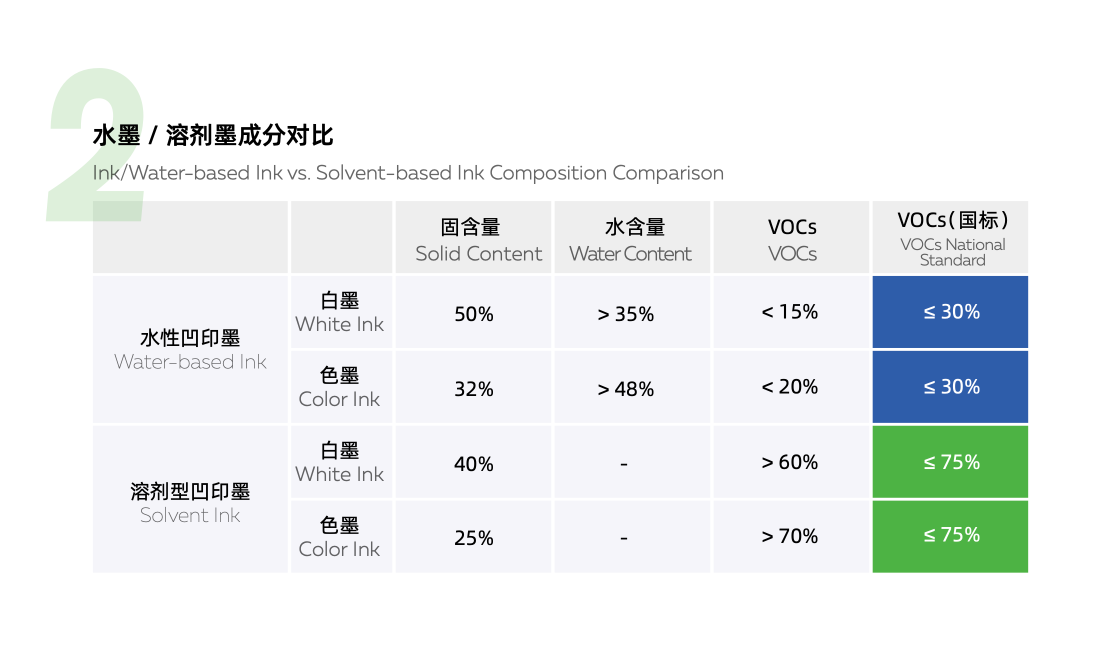

- Reduced Environmental Impact: Water-based inks contain less volatile organic compounds (VOCs) than solvent-based ones. This significantly reduces emissions during printing, contributing to a cleaner environment and healthier workplace.

- Enhanced Print Quality: Water-based inks dry faster and create a sharper image with more vibrant colors. This translates to eye-catching packaging that grabs consumers' attention and strengthens brand identity.

- Strong Adhesion: Unlike solvent-based inks that can crack or peel during the shrinking process, water-based inks form a strong bond with the plastic film. This ensures the design remains clear and intact even after heat shrinkage.

By choosing water-based inks for your heat shrink packaging, you're not just making a sustainable choice, you're also getting superior print quality and durability. Make the switch today and see the difference for yourself.

Understanding the Impact of Water-Based Ink on Shrink Wrap Equipment

Introducing water-based ink has transformed heat-shrink packaging and significantly impacted shrink-wrap equipment. With reduced maintenance costs, downtime, and an extended lifespan for heat shrinkers and packaging machines, businesses are experiencing enhanced efficiency and productivity like never before.

The shift to water-based ink has also positively impacted the environment, reducing harmful emissions and waste associated with traditional solvent-based inks. This eco-friendly approach benefits the planet and aligns with the growing consumer demand for sustainable packaging solutions. As businesses strive to meet these expectations, adopting water-based ink becomes a strategic advantage in reducing their environmental footprint and appealing to environmentally conscious consumers.

Qinghe Chemical: Pioneering Eco-Friendly Solutions

At the forefront of this eco-friendly revolution is Qinghe Chemical, a trailblazer in developing sustainable solutions for heat shrink packaging. Their commitment to innovation has propelled them to take charge of providing safe and compliant water-based ink for various applications within the industry.

Qinghe Chemical's water-based ink offers many benefits for heat shrink packaging. Firstly, it provides a safer and more environmentally friendly alternative to traditional solvent-based inks, reducing the release of harmful chemicals into the atmosphere. Additionally, this innovative solution ensures compliance with stringent regulations, giving businesses peace of mind when meeting industry standards. Furthermore, using water-based ink in heat shrink packaging results in vibrant and high-quality printing, enhancing the overall visual appeal of products without compromising sustainability.

Benefits of Using Water-Based Ink in Heat Shrink Packaging

Water-based ink offers many benefits when it comes to heat shrink packaging. Firstly, it significantly enhances sustainability and eco-friendliness by reducing harmful chemicals and solvents. This aligns with the growing demand for environmentally conscious packaging solutions, making water-based ink a top choice for businesses looking to reduce their carbon footprint.

1. Enhanced Sustainability and Eco-Friendliness

Water-based ink in heat shrink packaging minimizes the release of volatile organic compounds (VOCs) into the environment, making it a more eco-friendly option than traditional solvent-based inks. This reduces harm to the environment and creates a safer working environment for employees involved in the packaging process.

Furthermore, water-based ink in heat shrink packaging offers improved visual appeal and print quality compared to solvent-based inks. The colors appear more vibrant, and the images more crisp, enhancing the overall aesthetic of the packaging. This can help products stand out on store shelves and attract more consumer attention, increasing sales.

2. Improved Visual Appeal and Print Quality

Water-based ink is known for producing vibrant and high-quality prints on heat shrink materials, enhancing the visual appeal of packaged products. The colors are more vivid and consistent, resulting in eye-catching packaging that stands out on retail shelves, ultimately attracting more consumers.

Water-based ink is also compatible with various heat shrink packaging materials, including PVC, PETG, and OPS. This versatility allows water-based ink in multiple industries, from food and beverage to cosmetics and household products. Whether it's a smooth or textured surface, water-based ink adheres well to different substrates, ensuring consistent print quality across different packaging materials.

3. Compatibility with Various Heat Shrink Packaging Materials

Another advantage of water-based ink is its compatibility with various heat shrink packaging materials such as PVC, PETG, and polyolefin films. This versatility allows businesses to utilize water-based ink across different product lines without investing in separate printing equipment for each material type.

Furthermore, the compatibility of water-based ink with various heat shrink packaging materials also translates to cost savings for businesses. Companies can streamline their printing processes by using a single type of ink for different packaging materials and reduce the need for excess inventory and equipment. This simplifies operations and minimizes the risk of errors and inconsistencies in printing, leading to higher overall efficiency.

Impact on Shrink Wrap Equipment and Machinery

Water-based ink in heat shrink packaging significantly impacts shrink wrap equipment and machinery, leading to reduced maintenance costs and downtime. Water-based ink eliminates the need for harsh solvents, reducing wear and tear on heat shrinkers and shrink wrap equipment. This results in fewer breakdowns and maintenance requirements, ultimately saving time and money for businesses.

1. Reduced Maintenance Costs and Downtime

The transition to water-based ink in heat shrink packaging reduces maintenance costs and downtime for shrink wrap equipment. Frequent cleaning and maintenance are necessary for traditional solvent-based inks due to residue buildup, leading to costly downtimes. Water-based ink minimizes these issues, allowing for smoother operations with minimal interruptions.

Additionally, water-based ink reduces wear and tear on heat shrinker and packaging machines. The absence of harsh solvents means less corrosion and damage to equipment components, leading to a longer lifespan for the machinery. This saves on maintenance costs and ensures that the equipment operates at peak efficiency for an extended period.

2. Extended Lifespan of Heat Shrinker and Packaging Machine

By using water-based ink in heat shrink packaging, businesses can expect an extended lifespan for their heat shrinkers and packaging machines. The absence of harsh chemicals in water-based ink prevents corrosion and damage to equipment components, ensuring longevity and reliability. This ultimately leads to cost savings by avoiding premature replacements or repairs.

Furthermore, water-based ink also contributes to enhanced efficiency and productivity in heat shrink packaging operations. With reduced equipment downtime due to corrosion or damage, businesses can maximize their production output and meet customer demands more effectively. This improved efficiency saves time and allows businesses to take on more orders and grow their customer base, ultimately leading to increased revenue and profitability.

3. Enhanced Efficiency and Productivity

Water-based ink offers enhanced efficiency and productivity for heat shrink packaging operations. With reduced downtime for maintenance, businesses can maximize their production output without disruptions. Additionally, the compatibility of water-based ink with various heat shrink packaging materials contributes to smoother printing processes, further boosting overall efficiency.

In addition to improving efficiency and productivity, water-based ink offers environmental benefits by reducing the emission of volatile organic compounds (VOCs) during printing. This creates a healthier work environment for employees and aligns with sustainability goals for many businesses. By choosing water-based ink for heat shrink packaging operations, companies can demonstrate their commitment to eco-friendly practices and appeal to environmentally conscious consumers.

Now that we've explored the impact of water-based ink on shrink wrap equipment and machinery, let's delve into the pioneering role of Qinghe Chemical in innovating eco-friendly solutions for the heat shrink packaging industry!

The Role of Qinghe Chemical in Innovating Water-Based Ink

Revolutionizing Heat Shrink Packaging Industry

Qinghe Chemical has been at the forefront of revolutionizing the heat shrink packaging industry with its innovative water-based ink solutions. Developing eco-friendly alternatives to traditional solvent-based inks has set a new standard for sustainability and efficiency in shrink wrap equipment.

Qinghe Chemical's water-based ink solutions not only offer a more sustainable and environmentally friendly option for heat shrink packaging, but they also ensure the safety and compliance of food packaging. With strict regulations for food packaging materials, Qinghe Chemical's innovative inks provide a reliable solution that meets all necessary standards. This commitment to safety and compliance sets them apart in the industry, giving customers peace of mind when using their products for packaging food items.

Ensuring Safety and Compliance for Food Packaging

With a strong focus on safety and compliance, Qinghe Chemical's water-based ink formulations are specifically designed to meet the stringent requirements for food packaging. Their commitment to using non-toxic and odorless ingredients ensures that heat shrink packaging remains safe for consumers while complying with industry regulations.

As a result of Qinghe Chemical's dedication to safety and compliance, their water-based ink formulations have been widely recognized for their effectiveness in meeting the stringent requirements for food packaging. Using non-toxic and odorless ingredients, they have set a new standard for ensuring that heat shrink packaging remains safe for consumers while complying with industry regulations. This commitment to excellence has earned Qinghe Chemical a reputation as a trusted partner in the food packaging industry, providing both manufacturers and consumers peace of mind.

Case Studies and Success Stories

Through numerous case studies and success stories, Qinghe Chemical has demonstrated the effectiveness of its water-based ink in various heat-shrink packaging applications. From enhancing visual appeal to improving print quality, their solutions have consistently delivered exceptional results across different shrink wrap materials and equipment.

Furthermore, Qinghe Chemical's water-based ink has also proven to be a cost-effective solution for heat shrink packaging. By reducing the need for frequent ink changes and maintenance, their innovative product has helped companies save time and money in their packaging operations. This added benefit has made Qinghe Chemical a preferred choice for businesses to streamline production processes without compromising print quality.

Sustainable Solutions for the Future of Shrink Packaging

Using water-based ink in heat shrink packaging has revolutionized the industry, offering sustainable solutions for the future. By embracing Qinghe Chemical's eco-friendly innovations, companies can elevate their shrink packaging game while ensuring compliance and safety for food packaging.

Elevating Heat Shrink Packaging with Water-Based Ink Innovations

With the adoption of water-based ink, heat shrink packaging has been elevated to new heights of sustainability and visual appeal. This innovative solution enhances the overall print quality and contributes to a more eco-friendly approach to packaging.

Furthermore, water-based ink innovations in heat shrink packaging have paved the way for a more sustainable future in the industry. This eco-friendly approach aligns with the growing demand for environmentally conscious packaging solutions by reducing harmful chemicals and solvents. Not only does this benefit the planet, but it also resonates with consumers who are increasingly seeking products produced with minimal environmental impact.

As we look ahead, it's clear that water-based ink is paving the way for sustainable solutions in shrink packaging. Companies can now embrace a greener approach without compromising quality or efficiency, ensuring a brighter future for businesses and the environment. In addition to using water-based ink, manufacturers can explore innovative materials such as biodegradable shrink film made from plant-based polymers. This reduces the environmental impact of traditional shrink packaging and provides a unique selling point for brands looking to appeal to eco-conscious consumers.

Embracing Qinghe Chemical for Eco-Friendly Heat Shrink Packaging Success

Qinghe Chemical's commitment to pioneering eco-friendly solutions has made them a leader in providing water-based ink for heat shrink packaging. Their success stories and case studies demonstrate how this innovation has transformed shrink wrap equipment and machinery, setting new standards for sustainability in the industry.

Furthermore, Qinghe Chemical's dedication to sustainability extends beyond its water-based ink for heat shrink packaging. They have also developed innovative recycling programs and initiatives to minimize waste and reduce the environmental impact of their products. By embracing Qinghe Chemical, companies can benefit from eco-friendly packaging solutions and contribute to a more sustainable future for the industry as a whole.