Introduction

When it comes to printing and packaging, understanding the key differences between plastisol ink and water-based ink is crucial. With the rise of water-based inks in recent years, the environmental impact of printing has become a hot topic. As consumers demand more sustainable packaging solutions, the choice between plastisol and water-based ink has never been more important.

Understanding the Key Differences

The debate between plastisol ink and water-based ink boils down to their composition. Plastisol ink is a PVC-based ink that requires heat to cure, while water-based ink utilizes water as a solvent and air-dries or is cured with UV light. These differences have significant implications for performance and environmental impact.

The Rise of Water-Based Inks

With growing concerns about sustainability and eco-friendliness, the printing industry has seen a surge in the use of water-based inks. This shift is driven by a desire to reduce harmful chemicals and emissions associated with traditional plastisol inks, making it an attractive choice for environmentally conscious businesses.

The Environmental Impact

Water-based inks are a much greener alternative to traditional plastisol inks. Here's why:

- Reduced Toxicity: Plastisol inks contain harmful chemicals like phthalates and heavy metals, which can pose health risks to workers and contribute to pollution. Water-based inks are free from these toxic components.

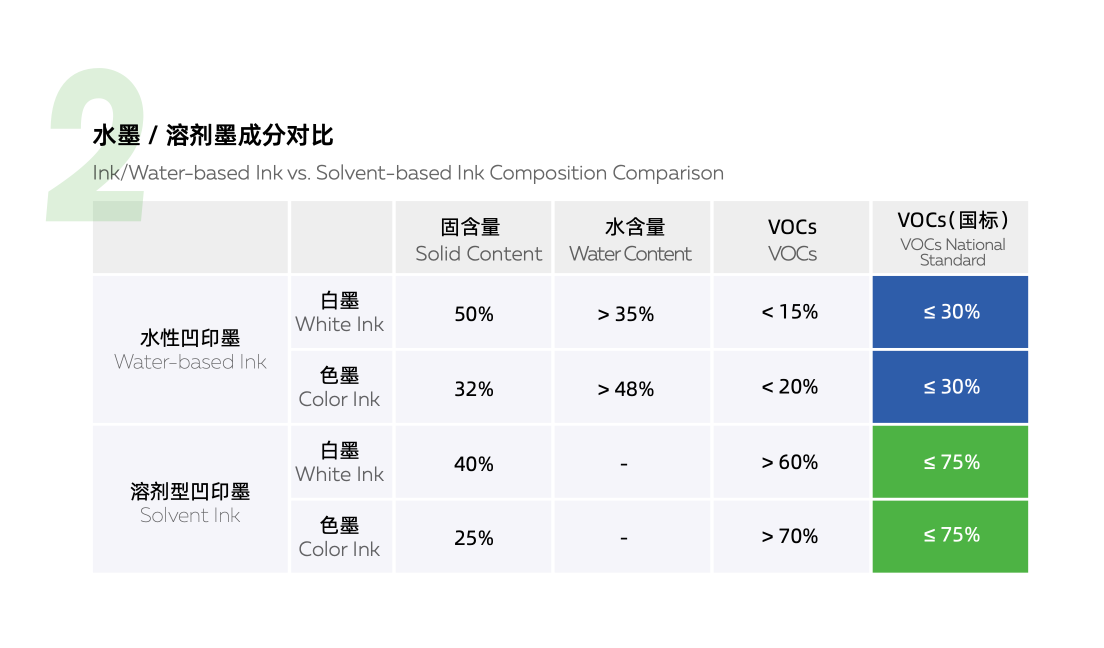

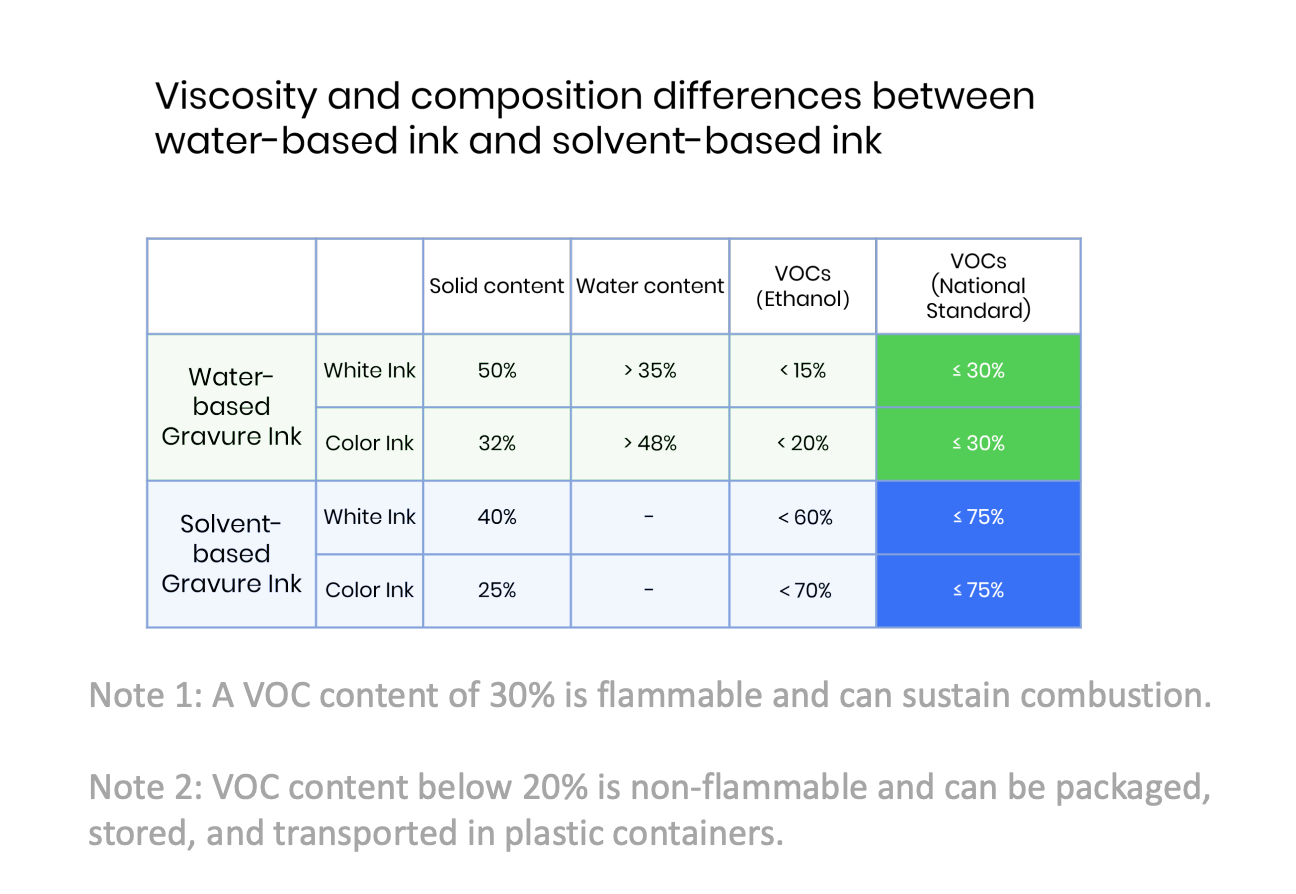

- Improved Air Quality: Water-based inks emit fewer volatile organic compounds (VOCs) during curing, improving indoor and outdoor air quality.

- Energy Efficiency: Water-based inks require lower curing temperatures than plastisol, saving energy.

- Sustainability: Water-based inks are often derived from renewable resources, making them a more sustainable choice.

Businesses can reduce their environmental impact by choosing water-based inks and creating healthier working environments.

Plastisol Ink vs Water Based Ink

Regarding performance on different materials, plastisol ink has long been the go-to choice for printing textiles due to its ability to sit on top of the fabric. However, water-based ink has made significant strides in recent years, offering improved adhesion and flexibility on various materials such as cotton, polyester, and nylon.

Performance on Different Materials

Water-based ink has proven to be a game changer in the industry by providing excellent adhesion and flexibility on a wide range of materials. Unlike plastisol ink, which tends to sit on top of the fabric, water-based ink penetrates the fibers, resulting in softer prints with better breathability.

Water-based ink's ability to adhere and flex on a wide range of materials makes it a top choice for manufacturers looking for versatility and quality. This ink doesn't just sit on the surface of the fabric like plastisol ink does; it actually penetrates the fibers, resulting in prints that are softer and more breathable. This means that clothing made with water-based ink is not only comfortable to wear but also durable and long-lasting.

Environmental Friendliness

Environmental friendliness is a major factor in the battle of plastisol vs. water-based ink. While plastisol ink contains PVC and phthalates, which are harmful to the environment, water-based ink is free from these toxic chemicals and is considered more eco-friendly.

In addition to being free from harmful chemicals, water-based ink is also easier to clean up and dispose of, making it a more sustainable choice for printing. Unlike plastisol ink, which requires harsh chemicals for cleanup and can contribute to air and water pollution, water-based ink can be easily cleaned with water and does not pose a threat to the environment. This makes it a more responsible option for businesses looking to reduce their environmental impact.

Cost Comparison

When choosing between plastisol and water-based inks for printing projects, it is important to consider the costs associated with each option. While plastisol inks may have lower initial costs, water-based inks can be more cost-effective in the long run due to several factors.

- Initial Costs: Plastisol inks generally have lower initial costs than water-based ones. This is because water-based inks require specialized equipment and longer drying times.

- Long-Term Savings: Water-based inks can be more cost-effective in the long run due to their lower energy consumption and reduced waste.

- Lower Energy Consumption: Water-based inks cure at a lower temperature than plastisol inks, which results in lower energy consumption.

- Reduced Waste: Water-based inks have a lower waste stream than plastisol inks, as they do not require chemicals like phthalates.

- Environmental Friendliness: Water-based inks are more environmentally friendly than plastisol inks, as they do not contain volatile organic compounds (VOCs).

In conclusion, while the initial investment in water-based inks may be higher, the long-term savings are significant. With lower energy consumption, reduced waste, and a smaller environmental footprint, water-based inks are a sustainable and cost-effective choice for businesses looking to reduce their printing costs.

Qinghe Chemical's Role

Innovations in Water-Based Gravure Inks

Qinghe Chemical has been at the forefront of developing innovative water-based gravure inks that offer superior performance and environmental benefits compared to traditional plastisol inks. These inks are formulated to provide excellent adhesion, color vibrancy, and printability on various substrates, making them a versatile choice for packaging and labeling applications.

In addition to their exceptional performance, Qinghe Chemical's water-based gravure inks also offer significant environmental benefits. By eliminating the need for harmful solvents and reducing volatile organic compound (VOC) emissions, these inks contribute to a healthier and safer working environment for printing facilities. Furthermore, their water-based formulation makes them easier to clean up and dispose of, reducing the overall environmental impact of the printing process. This aligns with the growing demand for sustainable packaging solutions in today's market.

Advantages of Flexible Food Packaging

With the increasing demand for sustainable packaging solutions, Qinghe Chemical's water-based gravure inks offer a significant advantage for flexible food packaging. These inks are free from harmful chemicals and heavy metals, ensuring that they meet stringent food safety regulations while reducing the environmental impact of packaging production.

Impact on Work Safety and Environmental Health

By choosing water-based gravure inks from Qinghe Chemical, printers can significantly improve work safety and environmental health within their facilities. Compared to plastisol inks, these inks emit lower levels of volatile organic compounds (VOCs), creating a safer working environment for employees while minimizing air pollution and contributing to a greener planet.

Polyurethane Water Based Ink

Polyurethane water-based ink offers numerous benefits when printing on bottles. Its flexibility and adhesion properties make it perfect for curved surfaces, ensuring the printed design stays intact without cracking or peeling. This ink also provides excellent color vibrancy, enhancing the visual appeal of the packaging.

Benefits of Printing on Bottles

Polyurethane water-based ink is a versatile and durable solution for bottle printing. It offers excellent adhesion to various plastic surfaces and exceptional resistance to fading and smudging.

- Superior Adhesion: It is formulated to adhere firmly to different plastic materials, ensuring sharp and vibrant prints on various bottle types.

- Excellent Durability: Resists fading, smudging, and repeated use, making it a cost-effective and long-lasting choice.

- Versatility: It is suitable for a wide range of plastic bottles, enabling consistent and high-quality printing across different product lines.

Polyurethane water-based ink provides a reliable and effective solution for bottle printing. It combines superior adhesion, durability, and versatility to deliver professional-looking results that enhance product branding and consumer appeal.

Compatibility with Different Surfaces

One key advantage of polyurethane water-based ink is its compatibility with a wide range of surfaces, including plastic, glass, and metal. This makes it a versatile option for businesses looking to print on various packaging materials without compromising print quality. The ink's ability to adhere to different surfaces ensures that the printed designs are durable and long-lasting.

In addition to its compatibility with various surfaces, polyurethane water-based ink also offers exceptional adhesion properties. This means the ink forms a strong bond with the surface it is applied to, preventing smudging or fading over time. This ensures that the printed designs maintain their crispness and clarity, even after prolonged use or exposure to environmental factors. Whether it's on plastic, glass, or metal, businesses can rely on the durability and longevity of printed materials.

Durability and Longevity

Polyurethane water-based ink offers exceptional durability and longevity when used for bottle printing. Its resistance to abrasion and chemicals ensures that the printed designs remain intact even under harsh conditions, such as exposure to moisture or handling during transportation. This durability makes it a reliable choice for businesses looking for long-lasting packaging solutions.

In conclusion, polyurethane water-based ink offers significant advantages when printing on bottles and other packaging materials. Its compatibility with different surfaces, durability, and longevity make it a sustainable choice for businesses looking to enhance their packaging with high-quality prints.

Print on Plastic with Water Based Ink

When it comes to printing on plastic, water-based ink offers exceptional quality and clarity. Unlike plastisol ink, water-based ink provides a more vibrant and sharp print on plastic surfaces, ensuring that the final product looks professional and eye-catching. The ink penetrates the surface of the plastic, resulting in a smooth and seamless finish that enhances the overall appearance of the printed material.

Quality and Clarity

Water-based ink delivers unparalleled quality and clarity when printing on plastic materials. The colors are more vivid and true to life, providing a visually appealing result that will capture attention. This makes it an ideal choice for businesses looking to create high-quality packaging or promotional materials that stand out.

Water-based ink also offers exceptional durability when printing on plastic materials, ensuring that the colors remain vibrant and true to life even after prolonged use or exposure to various environmental conditions. This means that businesses can rely on the longevity of their packaging or promotional materials without having to worry about fading or dullness over time. Additionally, the ink's resistance to abrasion and chemicals further enhances its suitability for various applications, providing a cost-effective and reliable solution for businesses seeking high-quality printing results.

Resistance to Abrasion and Chemicals

In addition to its superior visual appeal, water-based ink offers excellent resistance to abrasion and chemicals when printed on plastic. This ensures that the printed design remains intact and vibrant even after exposure to harsh environmental conditions or contact with various substances. As a result, products printed with water-based ink maintain their high-quality appearance for longer periods of time.

Sustainable Printing Solutions

Furthermore, water-based ink provides sustainable printing solutions for businesses looking to reduce their environmental impact. Unlike plastisol ink, which contains harmful chemicals and requires more energy-intensive curing processes, water-based ink is eco-friendly and emits fewer volatile organic compounds (VOCs) during printing. This makes it an environmentally responsible choice for companies committed to sustainable practices.

Additionally, water-based ink is easier to clean up compared to plastisol ink, reducing the amount of hazardous waste produced during the printing process. This not only benefits the environment but also contributes to a safer and healthier work environment for employees. By choosing water-based ink, businesses can demonstrate their commitment to sustainability while also promoting a more responsible and ethical workplace.

With its exceptional quality, durability, and sustainability benefits, water-based ink is clearly the superior choice for printing on plastic materials compared to plastisol ink.

The Future of Printing and Packaging

As the demand for environmentally friendly products grows, the printing and packaging industry is shifting towards using water-based inks over traditional plastisol inks. This shift is driven by the need to reduce environmental impact and provide sustainable packaging solutions for consumers.

Shift Towards Environmentally Friendly Inks

The shift towards water-based inks responds to the growing concern for environmental sustainability. Water-based inks are non-toxic, have lower VOC emissions, and are biodegradable, making them more eco-friendly than plastisol inks. As more companies prioritize sustainability, the demand for environmentally friendly inks will continue to rise.

Meeting Consumer Demands for Sustainable Packaging

Consumers are increasingly conscious of the environmental impact of their purchasing decisions, leading to a higher demand for sustainable packaging solutions. Water-based inks offer a more sustainable option for printing on various packaging materials such as paper, cardboard, and plastics, meeting consumer demands for eco-friendly packaging.

The Role of Printing Ink Companies

Printing ink companies are crucial in driving the transition towards environmentally friendly inks and sustainable packaging solutions. By investing in research and development of water-based ink technologies, these companies can provide innovative and eco-conscious printing solutions that meet both industry standards and consumer expectations.

Sustainable Printing for a Greener Future

When it comes to making informed printing choices, the debate of plastisol ink vs. water-based ink requires careful consideration. With the rise of eco-conscious consumers, the printing and packaging industry is shifting towards sustainable solutions, making Qinghe Chemical a leader.

Making Informed Printing Choices

As printers and manufacturers weigh the pros and cons of plastisol vs. water-based ink, it's crucial to prioritize not just performance but also environmental impact. By choosing water-based inks, businesses can align with consumer demands for sustainable packaging while still achieving high-quality results.

Qinghe Chemical Leading the Way

Qinghe Chemical's innovations in polyurethane water-based ink have revolutionized printing on bottles and other surfaces. Their commitment to environmentally friendly solutions has positioned them as a frontrunner in the industry, offering printers a way to meet consumer demands while maintaining top-notch quality.

As the world moves towards a greener future, printing ink companies like Qinghe Chemical become increasingly important. By providing sustainable options for printing on plastic and other materials, they are paving the way for an eco-friendly approach to printing and packaging.