Introduction

When it comes to printing, the choice between plastisol and water-based inks can significantly impact the environment and the quality of your prints. As a leading printing ink company, we understand the importance of making informed choices for sustainable printing practices. This article will explore the differences between plastisol and water-based ink, the environmental impact of printing inks, and the benefits of polyurethane water-based ink for a more eco-friendly approach to printing and packaging.

Understanding Plastisol and Water-Based Inks

Plastisol ink is a PVC-based ink that requires heat to cure, while water-based ink uses water as a solvent and air-dries or cures with UV light. Understanding these differences is crucial when choosing the right ink for your printing needs, especially when considering print on bottles or plastic materials.

The Environmental Impact of Printing Inks

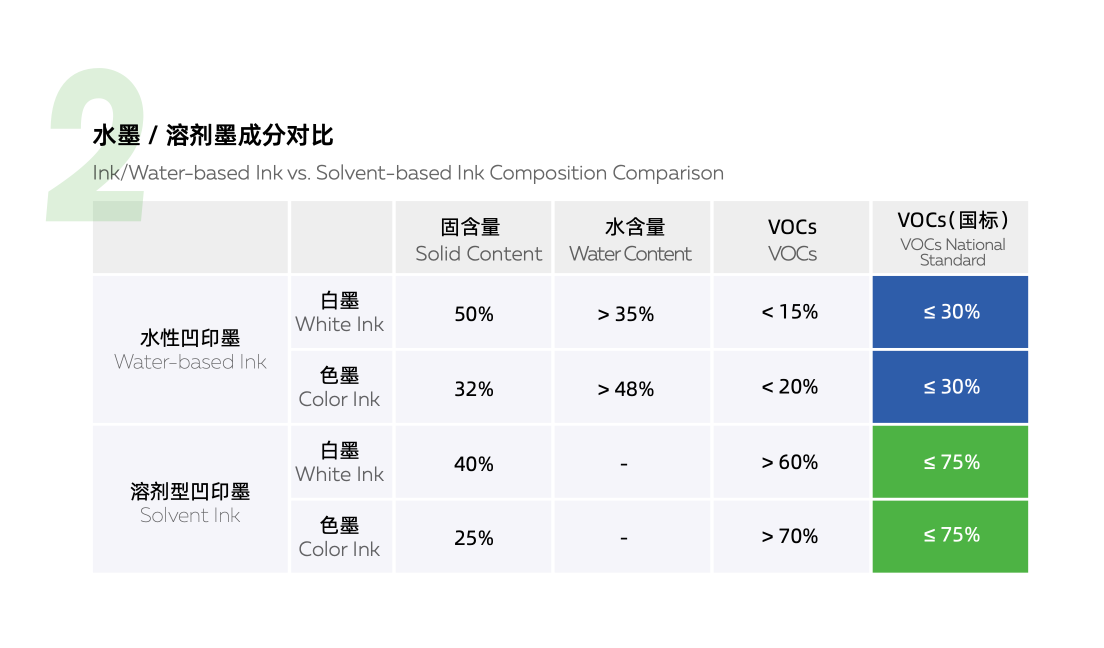

The environmental impact of printing inks cannot be overlooked. Traditional plastisol inks contain harmful chemicals and require more energy to cure, contributing to air pollution and waste. Polyurethane water-based inks offer a more sustainable alternative with lower VOC emissions and reduced energy consumption during curing.

The Benefits of Polyurethane Water-Based Ink

Polyurethane water-based ink is a versatile and sustainable option for various printing applications. It offers several advantages over traditional solvent-based inks, making it a preferred choice for many industries.

Here are some of the key benefits of polyurethane water-based ink:

- Enhanced Breathability: Fabric prints made with polyurethane water-based ink allow better air circulation, ensuring comfort and breathability.

- Softer Hand Feel: This type of ink provides a softer and more pleasant feel on printed surfaces, particularly textiles.

- Excellent Adhesion: Polyurethane water-based ink exhibits excellent adhesion to various substrates, including plastic, ensuring long-lasting and vibrant prints.

As a leading printing ink manufacturer, we are dedicated to developing and providing eco-friendly solutions that meet the evolving needs of the printing industry. Polyurethane water-based ink is a testament to our commitment to sustainable, high-performance printing technologies.

Plastisol vs Water-Based Ink: What's the Difference?

Regarding printing, the choice between plastisol and water-based ink can make a big difference. Plastisol ink is known for its durability and vibrant colors, making it a popular choice for t-shirt printing. On the other hand, water-based ink offers a softer feel and is more environmentally friendly. Understanding the key differences between these two types of inks can help you make the right decision for your printing needs.

Key Characteristics of Plastisol Ink

Plastisol ink is a popular choice for screen printing due to its versatility and ability to produce vibrant colors. However, the environmental impact of using this type of ink must be considered.

- PVC-based: Plastisol ink is made from polyvinyl chloride (PVC), a synthetic plastic that can release harmful chemicals during production and disposal.

- Heat-curing: Plastisol ink requires high temperatures to cure, which can contribute to air pollution.

- Surface-level application: The ink sits on top of the fabric rather than soaking in, making it more susceptible to cracking and peeling over time.

- Chemical solvents: The production and cleaning of plastisol ink often involve using harmful solvents that can contaminate water sources and harm wildlife.

While plastisol ink offers certain advantages, its environmental drawbacks make it less desirable for eco-conscious consumers. As the demand for sustainable products grows, there is an increasing focus on developing alternative inks that minimize environmental harm.

Benefits of Water-Based Ink for Printing on Bottles

Water-based ink offers several advantages over plastisol ink when it comes to printing on bottles. Water-based inks are more flexible and breathable, allowing them to adhere better to curved surfaces like bottles without cracking or peeling. Additionally, they are free from harmful chemicals and solvents, making them a safer and more sustainable option for bottle printing.

Water-based ink also offers better color vibrancy and opacity, resulting in more eye-catching and attractive bottle designs. This is especially important for brands looking to make a strong visual impact with their packaging. Additionally, water-based inks are easier to clean up and are less likely to cause clogging or build-up in printing equipment, saving time and maintenance costs for bottle manufacturers. With their superior adhesion and vibrant colors, water-based inks provide a high-quality and cost-effective solution for bottle printing.

Print On Plastic: Advantages of Water-Based Ink

Water-based ink offers a sustainable and high-quality printing solution for plastic materials.

- Environmental Friendliness: Unlike plastisol ink, water-based ink is free from PVC and phthalates, making it safer for consumers and the environment.

- Superior Softness and Breathability: When printed on plastic, water-based ink provides exceptional softness and breathability, making it ideal for reusable shopping bags and clothing labels.

- Natural Look and Feel: Water-based ink's ability to seamlessly blend into the plastic surface results in a more natural appearance and texture, enhancing the overall quality of the printed product.

By choosing water-based ink, companies can contribute to a greener future while delivering high-quality, environmentally friendly printed products.

The Evolution of Printing and Packaging

Qinghe Chemical's Role in Advancing Water-Based Gravure Inks

As a leading printing ink manufacturer, Qinghe Chemical has been at the forefront of advancing water-based gravure inks, providing sustainable and eco-friendly solutions for the packaging industry. By investing in research and development, they have developed innovative formulations that offer high-quality printing results while minimizing environmental impact. Their commitment to pushing the boundaries of water-based ink technology has set a new standard for printing on various substrates, including plastics.

In addition to their innovative ink formulations, Qinghe Chemical has also played a pivotal role in educating and training industry professionals on the benefits and applications of water-based gravure inks. By hosting workshops and seminars, they have helped to raise awareness about the environmental advantages of using water-based inks and share best practices for achieving optimal printing results. This proactive approach has not only contributed to the widespread adoption of eco-friendly inks. Still, it has also positioned Qinghe Chemical as a thought leader in promoting sustainability within the printing industry.

Promoting Sustainability in the Printing Industry

Qinghe Chemical is dedicated to promoting sustainability in the printing industry by offering polyurethane water-based ink solutions that reduce the carbon footprint of printing processes. Their focus on developing environmentally friendly alternatives to traditional plastisol inks has contributed to a shift towards more sustainable practices within the industry. By prioritizing sustainability, they are leading the way in driving positive change and encouraging other printing ink companies to follow suit.

Furthermore, Qinghe Chemical's water-based ink solutions are environmentally friendly and offer superior performance and durability compared to traditional plastisol inks. This means that companies can achieve sustainability without sacrificing the quality or longevity of their printed materials. As a result, more and more businesses are switching to water-based inks, significantly reducing the printing industry's overall environmental impact.

How Water-Based Inks are Revolutionizing Packaging Solutions

Water-based inks are revolutionizing packaging solutions by offering a more versatile and eco-friendly option for printing on bottles and plastic materials. With their ability to adhere to various substrates while maintaining vibrant colors, water-based inks provide a superior alternative to plastisol in terms of print quality and environmental impact. As more companies recognize the benefits of using water-based inks for their packaging needs, the industry is experiencing a transformation towards more sustainable and responsible printing practices.

Choosing the Right Ink for Your Printing Needs

When selecting ink for printing on plastic, it's essential to consider the plastic printer and the specific requirements of your application. A reliable printing ink company can offer guidance on choosing between plastisol and water-based ink, taking into account factors such as adhesion, durability, and color vibrancy.

Printer for Plastic: Considerations for Ink Selection

The type of printer used for plastic printing plays a crucial role in determining the suitable ink. Whether screen printing or digital printing, the printer's capabilities and compatibility with different inks must be carefully evaluated, a reputable printing ink manufacturer can provide insights into matching the right ink with your specific printer for plastic needs.

When considering the type of ink for plastic printing, it's important to consider your application's specific requirements. For instance, if you need to print on flexible plastic packaging, you'll want an ink that can withstand bending and stretching without cracking or fading. On the other hand, if you're printing on rigid plastic materials, durability and resistance to abrasion may be more critical factors to consider. By understanding the unique demands of your printing project, you can work with a printing ink manufacturer to select an ink that meets these requirements.

The Versatility of Water-Based Inks for Different Applications

Water-based inks offer remarkable versatility, making them suitable for a wide range of applications beyond bottles and plastic materials. From textiles to paper products, water-based inks can deliver exceptional results while minimizing environmental impact. Their adaptability makes them an attractive choice for businesses seeking diverse printing solutions.

Balancing Cost and Environmental Impact on Ink Choices

In today's environmentally conscious landscape, businesses increasingly prioritize sustainable practices without compromising cost efficiency. When weighing plastisol vs. water-based ink options, it's important to consider not only upfront costs but also long-term environmental impact. By choosing polyurethane water-based inks, companies can achieve a balance between cost-effectiveness and eco-friendliness.

Remember that when selecting the right ink for your printing needs, it's crucial to consider the specific requirements of your application and the capabilities of your printer for plastic. By working with a reputable printing ink company that offers versatile solutions like polyurethane water-based inks, you can achieve exceptional results and sustainability in your printing practices.

The Future of Printing Ink Technology

As the printing and packaging industry continues to evolve, the demand for sustainable and eco-friendly ink solutions is rising. Qinghe Chemical, a leading printing ink manufacturer, has been at the forefront of this innovation, developing an innovative approach to sustainable inks that prioritize environmental impact without compromising quality or performance.

Qinghe Chemical's Innovative Approach to Sustainable Inks

Qinghe Chemical has been dedicated to research and development, creating polyurethane water-based inks that offer a viable alternative to traditional plastisol. Their commitment to sustainability has led to the development of inks that are not only eco-friendly but also deliver vibrant colors and excellent adhesion on various substrates, making them an ideal choice for modern printing needs.

Meeting the Demands of Modern Consumers with Eco-Friendly Printing Solutions

Consumers are becoming increasingly conscious of environmental issues, so there is a growing demand for products and packaging that align with their values. Water-based inks provide a solution that meets these demands by offering a more sustainable option for printing on bottles, plastic, and other materials without sacrificing quality or durability.

The Growing Importance of Environmentally Friendly Printing Inks

The shift towards environmentally friendly printing inks is not just a trend but a necessity today. As businesses and consumers prioritize sustainability, printing ink companies must adapt to meet these changing needs. The industry can reduce its environmental impact by embracing water-based inks while still delivering high-quality printed materials.

Qinghe Chemical: Leading the Way in Eco-Friendly Inks

When it comes to sustainable printing practices, making informed choices is key. Understanding the benefits of polyurethane water-based ink and the environmental impact of plastisol vs. water-based ink can help you make the right decision for your printing needs. Qinghe Chemical, a leading printing ink manufacturer, is at the forefront of eco-friendly inks, promoting the shift towards environmentally conscious printing and packaging.

Making Informed Choices for Sustainable Printing Practices

Choosing between plastisol and water-based ink can significantly impact sustainability. By understanding the advantages of water-based inks for printing on bottles and plastic, you can make informed decisions that contribute to more eco-friendly printing practices. With options like polyurethane water-based ink, innovative solutions are available that prioritize both quality and sustainability.

As a prominent printing ink company, Qinghe Chemical is leading the way in developing eco-friendly inks that meet the demands of modern consumers. Their commitment to advancing water-based gravure inks and promoting sustainability in the industry demonstrates their dedication to providing environmentally friendly solutions for printing and packaging needs.

The Shift Towards Environmentally Conscious Printing and Packaging

The future of printing ink technology is undoubtedly moving towards more environmentally conscious practices. With a growing importance placed on sustainable solutions, there's an increasing demand for eco-friendly options from both consumers and businesses alike. As this shift continues, companies like Qinghe Chemical are crucial in driving positive change within the industry.

As the demand for eco-friendly printing and packaging options continues to grow, companies like Qinghe Chemical are stepping up to the plate by developing innovative solutions that prioritize sustainability without compromising quality. By investing in research and development, these companies can create cutting-edge products that meet the needs of environmentally conscious consumers and businesses. This proactive approach benefits the planet and positions these companies as leaders in the industry, setting a new standard for responsible manufacturing practices.