Introduction

The choice of ink is crucial for high-quality printing. Understanding the differences between solvent-based and water-based inks, as well as the advantages of low VOC inks, is essential for making informed decisions. This introduction will delve into the world of solvent-based printing inks and explore the role of Qinghe Chemical in shaping the future of this industry.

Understanding Solvent Based Printing Inks

Solvent based printing inks are a popular choice for various applications due to their durability and versatility. These inks are formulated with organic solvents that evaporate during drying, leaving behind vibrant and long-lasting colors on various substrates.

Solvent Based Ink vs Water Based Ink

The debate between solvent-based ink and water-based ink has been ongoing within the printing industry. While water-based inks offer environmental benefits, solvent-based inks are preferred for their ability to adhere to non-porous surfaces and their resistance to fading or smudging.

Advantages of Low VOC Inks

Low VOC (volatile organic compound) inks are becoming increasingly popular because they offer a win-win for both the environment and human health. Here are some of the key benefits of using low VOC inks:

- Reduced Environmental Impact: Low VOC inks minimize the release of harmful chemicals into the atmosphere, contributing to a healthier planet.

- Improved Indoor Air Quality: Using low VOC inks can significantly reduce indoor air pollution, creating a healthier and more comfortable environment for everyone.

- Enhanced Print Quality: Low VOC inks deliver excellent print quality, ensuring your projects look sharp and professional.

- Safe for Human Health: Low VOC inks are formulated to minimize health risks associated with exposure to harmful chemicals.

Switching to low VOC inks is a responsible choice that benefits both the environment and your health.

The Role of Qinghe Chemical

Qinghe Chemical has been at the forefront of developing innovative solutions for solvent based printing inks, including low VOC formulations that meet stringent regulatory standards. Their expertise and commitment to sustainability have made them a leading player in the industry.

The Future of Solvent Based Printing Inks

As technology continues to evolve, so does the future of solvent based printing inks. With a focus on sustainability and environmental concerns, there is a growing demand for eco-friendly alternatives that deliver exceptional print quality without compromising performance.

The Basics of Solvent Based Printing Inks

What are Solvent Based Printing Inks?

Solvent based printing inks are a type of ink that uses organic solvents as the main carrier fluid. These inks are known for their fast drying time and ability to adhere to various substrates, making them popular for industrial and commercial printing applications.

Solvent based printing inks are also known for their vibrant and long-lasting colors, making them ideal for outdoor signage, packaging, and labels. The organic solvents in these inks evaporate quickly during printing, leaving behind a durable and high-quality finish. Additionally, solvent based inks are resistant to water, chemicals, and UV light, ensuring that the printed materials maintain their integrity even in harsh environmental conditions.

Composition and Characteristics of Solvent Based Inks

Solvent-based inks are a popular choice for industrial printing due to their unique composition and characteristics. Here's a breakdown of what they're made of and why they're so useful:

1. Components: Solvent-based inks contain three main ingredients:

- Pigments: These provide the ink's color.

- Resins: These act as binders, holding the pigments together and adhering them to the printing surface.

- Volatile Organic Compounds (VOCs): These solvents help the ink dry quickly by evaporating after application.

2. Fast Drying and Vibrant Colors: The rapid evaporation of VOCs allows solvent-based inks to dry quickly, resulting in sharp and vivid prints.

3. Durability: Solvent-based inks create a strong bond with the printing surface, making them resistant to scratches, fading, and harsh weather conditions. This makes them ideal for outdoor applications and long-lasting products.

4. Diverse Applications: Due to their durability and vibrant colors, solvent-based inks are widely used in industries like:

- Packaging: Printing on plastic, metal, and coated paperboard for food, beverages, and other products.

- Signage: Creating weather-resistant signs and banners for outdoor advertising.

- And many more!

Solvent-based inks offer fast drying times, vibrant colors, and excellent durability, making them a valuable tool for industrial printing applications.

Applications and Industries Using Solvent Based Inks

Solvent based inks are widely used in industries such as packaging, signage, labels, and outdoor advertising due to their weather-resistant properties. They are also favored for printing on non-absorbent materials like plastics, metals, and films, making them versatile for various applications.

Solvent based inks are also commonly used in the automotive industry for printing on vehicle parts and components. Their durability and resistance to harsh environmental conditions make them ideal for applications that require long-lasting and high-quality prints. Additionally, solvent based inks are favored in the electronics industry for printing on circuit boards and electronic components, where precision and reliability are essential. This versatility makes solvent based inks a go-to choice for a wide range of industrial applications.

Solvent Based Ink vs Water Based Ink

A Comparison of Solvent Based and Water Based Inks

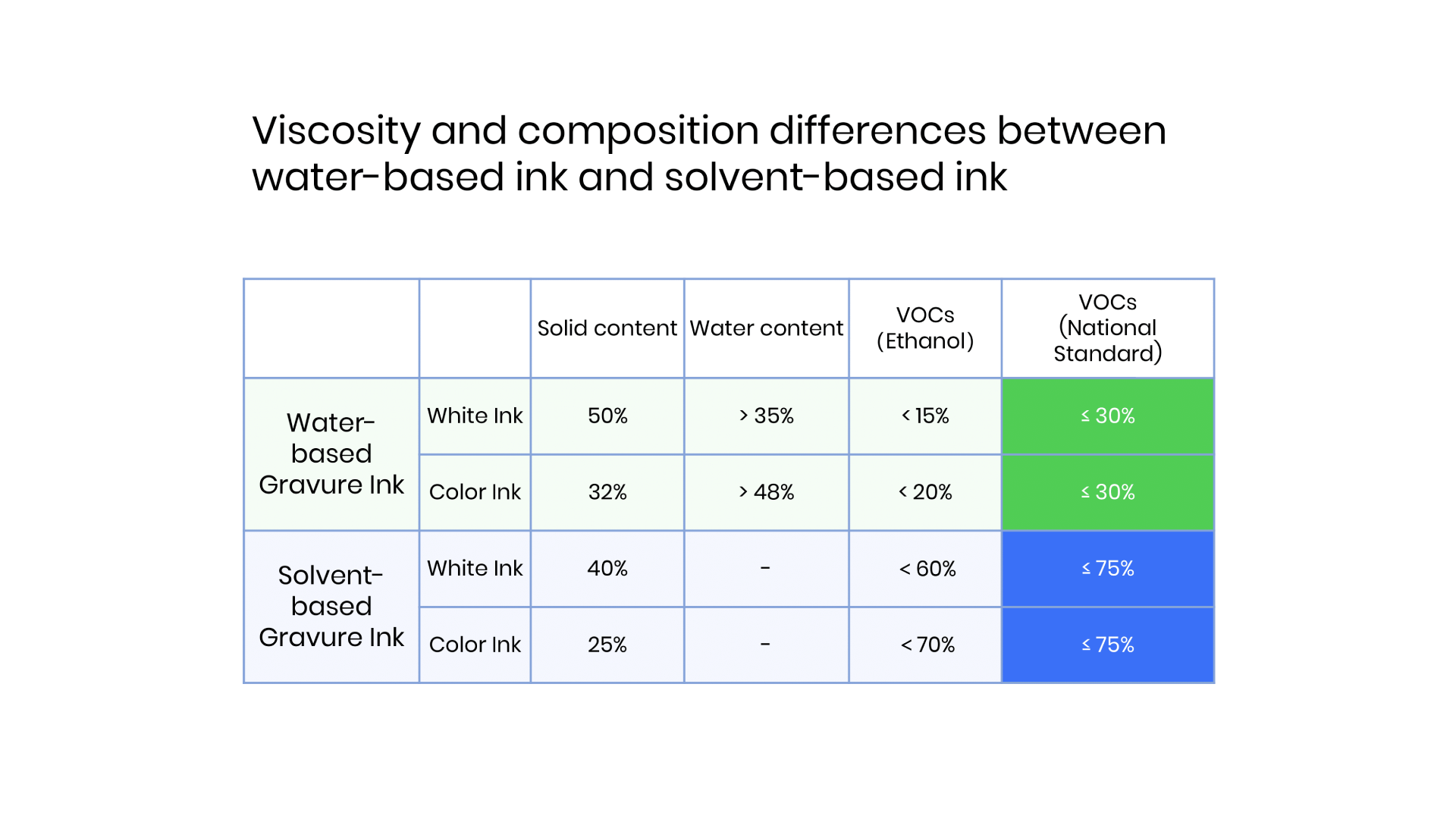

When comparing solvent based printing inks with water based inks, it's important to consider their chemical composition and application methods. Solvent based inks use organic solvents as the carrier for the pigment, while water based inks use water as the primary solvent. Solvent based inks are known for their durability and resistance to moisture, making them ideal for outdoor applications. In contrast, water based inks are more environmentally friendly and have lower VOC emissions.

Pros and Cons of Solvent Based Inks

One of the main advantages of solvent based inks is their ability to adhere to a wide range of substrates, including non-porous materials like plastics and metal. They also dry quickly, which increases production efficiency. However, using volatile organic compounds (VOCs) in solvent based inks poses health and environmental risks. Additionally, solvent based inks require proper ventilation during printing processes to avoid exposure to harmful fumes.

Environmental Impact of Solvent Based Inks

Solvent based printing inks have been associated with air pollution due to the release of VOCs during the drying process. These emissions contribute to smog formation and can harm human health. Disposing used solvents is also challenging, as they can contaminate soil and water sources if not handled properly. As environmental awareness grows, there is an increasing demand for sustainable alternatives such as low VOC inks.

Advantages of Low VOC Inks

Understanding VOCs in Printing Inks

Volatile Organic Compounds (VOCs) are chemicals that vaporize into the air, contributing to air pollution and posing health risks. Solvent based printing inks typically contain high levels of VOCs, which can have negative impacts on both the environment and human health.

Switching to low VOC inks can provide several benefits for both the environment and human health. Low VOC inks help minimize air pollution and improve overall air quality by reducing harmful chemicals released into the air. Additionally, using low VOC inks can contribute to a healthier work environment for employees in printing facilities, as they are not exposed to high levels of toxic fumes daily. Furthermore, choosing low VOC inks demonstrates a commitment to sustainability and corporate social responsibility, which can enhance a company's reputation and appeal to environmentally conscious consumers.

Benefits of Using Low VOC Inks

Low VOC inks are a better choice for both the environment and your health. Here are some key benefits:

- Reduced Air Pollution: Low VOC inks minimize the release of harmful emissions during printing. This helps improve overall air quality, both indoors and outdoors.

- Safer Work Environment: Low VOC inks contain fewer hazardous chemicals, reducing the risk of exposure for printing industry workers. This leads to a healthier and safer work environment.

- Easier Clean Up: Low VOC inks are often easier to clean up and dispose of than traditional ones. This minimizes the chance of accidents and reduces potential environmental harm.

Switching to low VOC inks is a simple step towards a more sustainable and health-conscious printing process.

Regulations and Compliance for VOC Emissions

In response to growing environmental concerns, regulatory bodies have implemented strict guidelines and standards for VOC emissions from industrial processes, including printing. Utilizing low VOC inks helps businesses comply with these regulations and demonstrates a commitment to sustainability and responsible environmental stewardship.

Furthermore, using low VOC inks can also lead to business cost savings. By reducing the amount of harmful chemicals used in the printing process, companies can minimize their environmental impact while also cutting down on expenses related to waste disposal and regulatory compliance. This benefits the planet and contributes to a healthier bottom line for businesses, making it a win-win solution for all parties involved.

Now, let's explore The Role of Qinghe Chemical in promoting eco-friendly ink solutions.

The Role of Qinghe Chemical

History and Expertise of Qinghe Chemical

Qinghe Chemical has a rich history of over 20 years in the production and development of high-quality solvent-based printing inks. Their expertise in chemical formulations and printing technologies has made them a trusted name in the industry. They have a proven track record of delivering innovative solutions to meet the evolving needs of their clients.

In response to the growing demand for environmentally friendly printing solutions, Qinghe Chemical has expanded its expertise to include the development of high-quality water-based inks. Leveraging its extensive knowledge of chemical formulations and printing technologies, the company has successfully transitioned into this new market segment, offering innovative solutions that meet its clients' performance and sustainability requirements. This strategic move demonstrates Qinghe Chemical's adaptability and forward-thinking approach and solidifies its position as a leader in the industry.

Qinghe Chemical's Contribution to Water-Based Inks

Qinghe Chemical has made significant contributions to the development of water-based inks in response to the growing demand for environmentally friendly printing solutions. By leveraging their expertise in solvent based ink technology, they have successfully formulated low VOC inks that offer superior performance while minimizing environmental impact.

Furthermore, Qinghe Chemical has invested in research and development to create water-based inks that are not only eco-friendly but also cost-effective for printing companies. By optimizing the formulation of their inks, they have been able to balance environmental sustainability and economic feasibility. This has allowed businesses to adopt water-based inks without compromising quality or profitability, marking a significant milestone in the printing industry's shift towards greener solutions.

Innovations in Printing Technology by Qinghe Chemical

Qinghe Chemical continues to drive innovation in printing technology, constantly researching and developing new formulations for solvent based printing inks that are more sustainable and efficient. Their commitment to staying ahead of industry trends ensures they remain at the forefront of eco-friendly ink solutions, setting new standards for quality and performance.

The Future of Solvent Based Printing Inks

Trends and Developments in Solvent Based Printing Inks

As technology continues to advance, the future of solvent-based printing inks looks promising. New trends include the development of high-performance inks that offer improved adhesion, color vibrancy, and durability. Additionally, there is a growing demand for solvent-based inks that are compatible with various substrates, catering to a wide range of printing applications.

Furthermore, the industry is seeing a shift towards solvent-based inks that are more environmentally friendly. Manufacturers are investing in research and development to create inks with lower volatile organic compound (VOC) emissions, reducing their impact on air quality. This aligns with the growing consumer demand for sustainable and eco-friendly products, driving the need for greener printing solutions.

Sustainability and Environmental Concerns

With increasing environmental awareness, the printing industry is shifting towards more sustainable practices. This has led to the development of eco-friendly solvent based inks with reduced VOC emissions and improved recyclability. Manufacturers are also exploring renewable and bio-based solvents as alternatives to traditional petroleum-based solvents, further reducing the environmental impact of solvent based printing inks.

As the demand for sustainable printing practices continues to grow, manufacturers are also focusing on developing eco-friendly printing materials. This includes the use of recycled paper and cardboard as well as biodegradable packaging for printed products. By incorporating these sustainable materials into the printing process, companies can further reduce their environmental footprint and appeal to environmentally conscious consumers.

Evolution of Printing Technologies and Materials

Advancements in printing technologies and materials are driving innovation in solvent based ink formulations. From improved print heads and ink delivery systems to new substrate materials, these developments are enhancing the performance and versatility of solvent based printing inks. This evolution paves the way for more efficient and cost-effective printing processes across various industries.

Furthermore, the development of eco-friendly solvent based inks is also a significant trend in the evolution of printing technologies and materials. As environmental concerns continue to grow, there is a rising demand for printing solutions that minimize impact on the planet. Manufacturers are investing in research and development to create solvent based inks that are free from harmful chemicals and have reduced emissions, while still maintaining high-quality print results. This shift towards sustainability is reshaping the printing industry and driving the adoption of greener practices.

Qinghe Chemical: Leading the Way in Eco-Friendly Printing Inks

In a world where sustainability is becoming increasingly important, embracing sustainable printing solutions is crucial. You can reduce your environmental impact by choosing low VOC inks while still achieving high-quality prints. Qinghe Chemical is leading the way in eco-friendly printing inks, offering innovative solutions prioritizing performance and sustainability.

Embracing Sustainable Printing Solutions

As the demand for eco-friendly products grows, businesses must embrace sustainable printing solutions. Companies can minimize their carbon footprint without compromising print quality by opting for solvent-based printing inks with low VOC emissions. This shift towards sustainability benefits the environment and enhances brand reputation and customer loyalty.

Choosing the Right Ink for Your Printing Needs

When choosing between solvent-based and water-based inks, it's important to consider your specific printing needs. While water-based inks may be more environmentally friendly, solvent-based inks offer superior adhesion and durability, making them ideal for certain applications. Understanding the pros and cons of each type of ink will help you make an informed decision that aligns with your business goals.

Qinghe Chemical has established itself as a leader in developing low VOC solvent based printing inks. With a strong focus on innovation and environmental responsibility, Qinghe Chemical has set new standards for eco-friendly ink formulations that deliver exceptional results. Their commitment to sustainability and cutting-edge technology makes them a trusted partner for businesses seeking to reduce their environmental impact.

By embracing sustainable printing solutions, choosing the right ink for your specific needs, and partnering with industry leaders like Qinghe Chemical, you can positively impact both your business and the environment while achieving outstanding print results with solvent-based ink options.