Introduction

When it comes to superior solutions for gravure printing, the choice of ink plays a crucial role in achieving high-quality results. Water-based gravure ink has been gaining traction in the industry due to its numerous benefits, and Qinghe Chemical has been at the forefront of this innovation, significantly impacting the gravure ink industry.

Superior Solutions for Gravure Printing

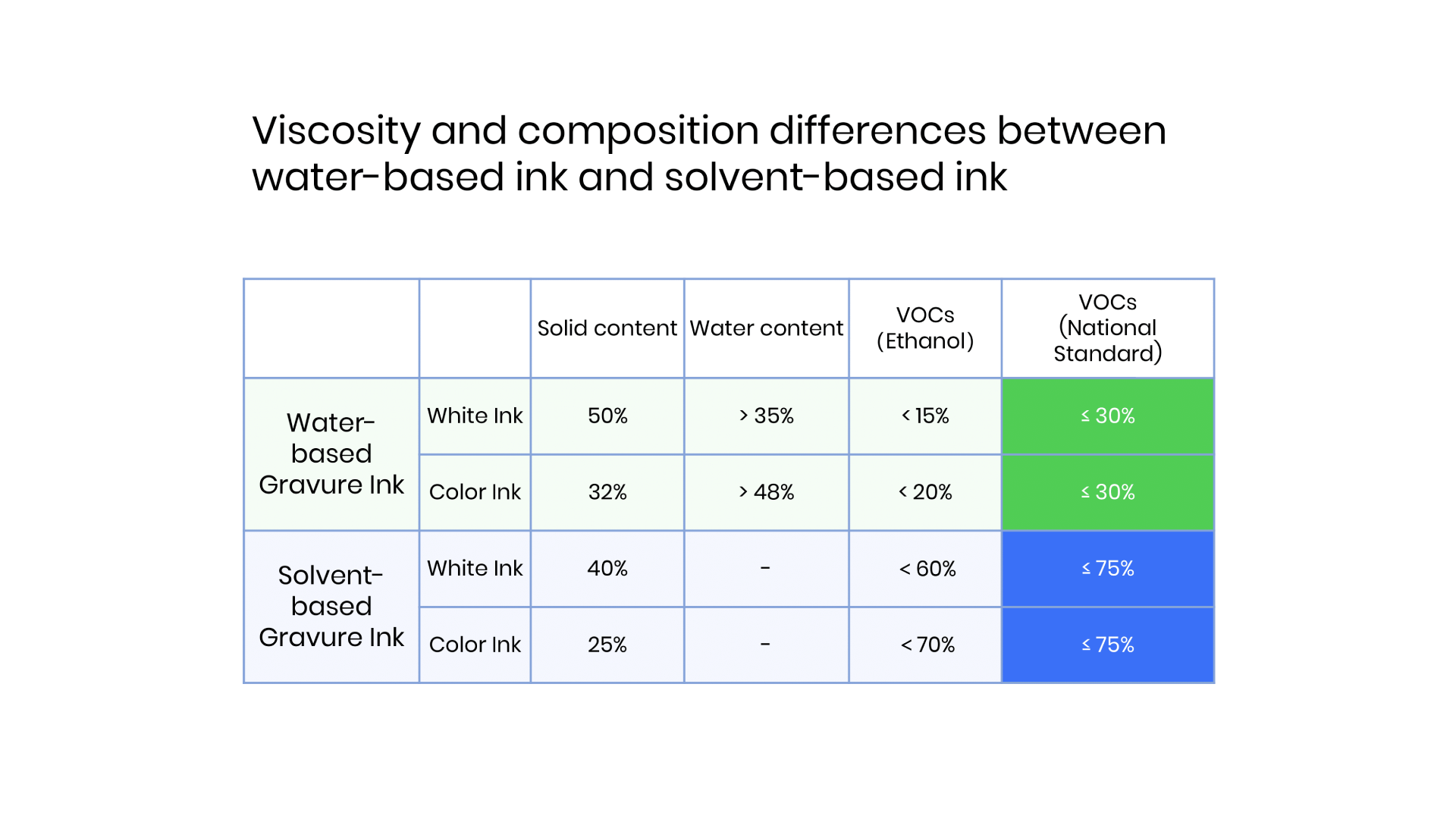

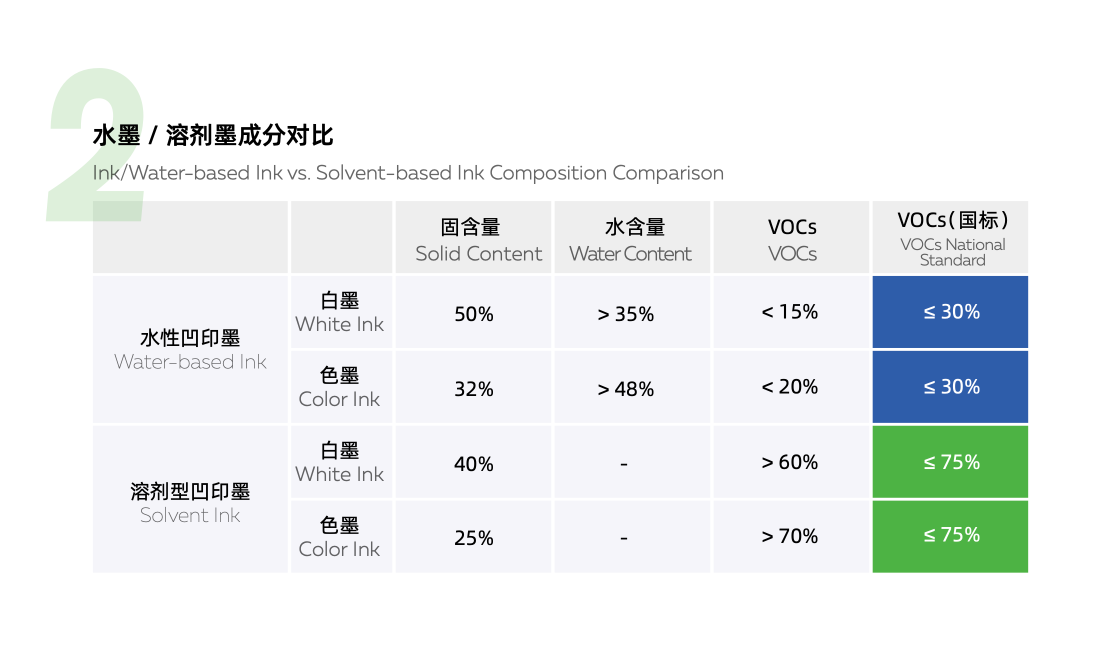

Gravure printing ink is essential for creating intricate and detailed prints on various substrates such as paper, film, and foil. The formulation and viscosity of gravure ink are critical factors determining print quality and performance. With Qinghe Chemical's expertise in developing advanced ink solutions, printers can easily achieve optimal results. Additionally, our water-based gravure ink offers environmental benefits by reducing volatile organic compound (VOC) emissions, making it a more sustainable option for printing operations. This meets regulatory requirements and demonstrates a commitment to eco-friendly practices, which can be a valuable selling point for businesses looking to appeal to environmentally conscious consumers.

Benefits of Water-Based Gravure Ink

Water-based gravure ink is gaining traction in the printing industry due to its numerous advantages over traditional solvent-based inks. Here are some key benefits:

- Reduced Environmental Impact: Water-based inks contain minimal to no Volatile Organic Compounds (VOCs), significantly reducing harmful emissions and contributing to a healthier planet.

- Improved Workplace Safety: With minimal VOCs, water-based inks create a safer work environment for printers by eliminating exposure to harsh chemicals and fumes.

- Enhanced Print Quality and Vibrancy: Advances in water-based ink technology allow for sharper images, finer details, and richer colors, ideal for high-end packaging and labels.

- Sustainable Printing Practices: Water-based inks align perfectly with the growing demand for eco-friendly printing solutions, allowing businesses to demonstrate their commitment to sustainability.

- Competitive Advantage: The superior print quality achievable with water-based inks can give businesses a competitive edge by creating visually appealing and high-impact printed materials that make their products stand out.

In conclusion, water-based gravure ink offers a compelling combination of environmental responsibility, improved workplace safety, and exceptional print quality, making it a smart choice for printers and businesses.

Qinghe Chemical's Impact on Gravure Ink Industry

As a leading manufacturer of gravure printing ink, Qinghe Chemical has significantly impacted the industry by providing innovative water-based solutions that meet the evolving needs of printers and consumers alike. Their commitment to sustainability and high-performance formulations sets them apart in the competitive market.

By embracing water-based gravure ink technology from Qinghe Chemical, printers can achieve superior print quality while reducing their environmental footprint and meeting consumer demand for eco-friendly packaging solutions. With their expertise in formulation and viscosity control, Qinghe Chemical continues to lead the way towards a greener future for the gravure printing industry.

The Advantages of Water-Based Gravure Ink

Water-based gravure ink offers numerous advantages, making it a superior choice for gravure printing applications. With low VOC emissions, this type of ink significantly reduces air pollution and contributes to a healthier work environment. The absence of harmful solvents also improves work safety by minimizing the risk of exposure to toxic chemicals, making it a preferred option for printing facilities. Furthermore, water-based gravure ink is environmentally compatible, aligning with sustainable practices and reducing the printing industry's ecological footprint.

1. Low VOC Emissions

Water-based gravure ink results in significantly lower volatile organic compounds (VOCs) levels than traditional solvent-based inks. This reduction in VOC emissions supports environmental protection efforts and helps printing facilities comply with stringent air quality regulations. By choosing water-based gravure ink, businesses can demonstrate their commitment to sustainability while maintaining high-quality printing standards.

In addition to reducing VOC emissions, water-based gravure ink offers improved work safety for printing facility employees. Traditional solvent-based inks can pose health risks because they release harmful chemicals into the air during printing. By using water-based inks, businesses can create a safer working environment for their staff, reducing the risk of respiratory issues and other health concerns associated with exposure to VOCs. This prioritization of employee well-being can also contribute to higher morale and productivity within the workplace.

2. Improved Work Safety

Water-based gravure ink eliminates the health risks associated with prolonged exposure to solvent fumes, providing a safer working environment for printing industry employees. By minimizing the inhalation of harmful chemicals, this type of ink contributes to improved respiratory health and well-being among workers. As a result, businesses can prioritize employee safety while enhancing productivity and morale within their operations.

Furthermore, water-based gravure ink is also more environmentally friendly than solvent-based ink. With reduced emissions of volatile organic compounds (VOCs), this type of ink helps minimize air pollution and its impact on the surrounding ecosystem. By choosing water-based gravure ink, printing businesses can demonstrate their commitment to sustainability and corporate social responsibility, appealing to environmentally conscious consumers and stakeholders.

3. Environmental Compatibility

Water-based gravure ink's eco-friendly nature makes it an ideal choice for companies seeking to reduce their environmental impact. Businesses can align with consumer demand for environmentally friendly practices and products by opting for this sustainable solution. Water-based gravure ink supports the creation of eco-friendly packaging materials that resonate with environmentally conscious consumers, ultimately enhancing brand reputation and market competitiveness.

The Green Future of Gravure Printing

Qinghe Chemical's Commitment to Sustainability

Qinghe Chemical is dedicated to sustainability in the gravure ink industry. It offers water-based gravure ink solutions that reduce environmental impact. By prioritizing eco-friendly practices and materials, Qinghe Chemical is leading towards a greener future for gravure printing.

In addition to offering water-based gravure ink solutions, Qinghe Chemical is committed to reducing environmental impact through its production processes. By implementing energy-efficient technologies and reducing waste generation, the company strives to minimize its carbon footprint and contribute to a more sustainable industry. Furthermore, Qinghe Chemical actively seeks partnerships with suppliers who share its commitment to eco-friendly practices, ensuring that its entire supply chain reflects its dedication to sustainability.

Reducing Environmental Impact

With water-based gravure ink formulations, Qinghe Chemical is actively reducing the environmental impact of traditional solvent-based inks. Their innovative approach contributes to a healthier planet and a more sustainable printing industry by lowering VOC emissions and minimizing harmful chemicals.

Meeting Consumer Demand for Eco-Friendly Packaging

As consumer demand for eco-friendly packaging continues to rise, Qinghe Chemical's water-based gravure ink aligns with this trend. Brands and manufacturers can meet the growing need for sustainable packaging solutions by utilizing these environmentally compatible inks, satisfying consumer preferences and regulatory requirements.

In addition to being environmentally friendly, Qinghe Chemical's water-based gravure ink also offers high-quality printing results, ensuring that brands and manufacturers do not have to compromise on the visual appeal of their packaging. This means businesses can continue to create eye-catching designs and vibrant colors while prioritizing sustainability. By choosing these inks, companies can demonstrate their commitment to both environmental responsibility and product presentation, ultimately enhancing their brand reputation in the eyes of consumers.

Remember to use environmentally friendly practices when choosing your next gravure ink solution!

Formulation and Viscosity of Gravure Ink

Gravure ink formulation is crucial to achieving optimal printing results. The precise combination of ingredients in gravure ink determines its viscosity, adhesion, and drying time, all impacting print quality. At Qinghe Chemical, our expertise in formulating water-based gravure inks allows us to create customized solutions for different applications, ensuring our clients achieve the best possible printing results.

Achieving Optimal Printing Results

With our extensive knowledge of gravure ink formulation, we can tailor the viscosity of the ink to suit specific printing requirements. This enables our clients to achieve sharp, consistent print results with minimal downtime. Our water-based gravure inks offer excellent flow properties and color retention, allowing for high-quality printing on various substrates.

Enhancing Print Quality

The right combination of ingredients in gravure ink is essential for enhancing print quality. Our formulations are designed to minimize dot gain, improve color vibrancy, and ensure excellent adhesion to substrates. Printers can achieve superior print clarity and detail without sacrificing production efficiency by using water-based gravure inks with carefully controlled viscosity.

Customized Solutions for Different Applications

Different applications require different formulations of gravure ink to meet specific performance criteria. Qinghe Chemical offers customized solutions tailored to each application's unique requirements, whether packaging materials or decorative prints. Our expertise in adjusting ink viscosity and formulation allows us to provide versatile gravure inks that deliver exceptional results across various printing applications.

By carefully formulating water-based gravure inks with precise viscosity control, Qinghe Chemical ensures that our clients achieve optimal printing results while enhancing print quality across various applications.

The Role of Ingredients in Gravure Ink

When it comes to gravure ink, the ingredients play a crucial role in determining the quality and performance of the final product. Qinghe Chemical is renowned for its innovative formulations, carefully selecting the finest components to create high-performance inks that meet industry standards and regulations. With a deep understanding of the intricacies of gravure ink formulation, Qinghe Chemical ensures that each ingredient contributes to the overall excellence of its products.

Qinghe Chemical's Innovative Formulations

Qinghe Chemical's dedication to research and development has led to groundbreaking formulations that set their gravure inks apart from the competition. By combining cutting-edge technology with a deep knowledge of ink chemistry, they have created formulations that deliver exceptional print results and prioritize environmental sustainability. Their commitment to innovation ensures that their gravure inks remain at the forefront of industry advancements.

Creating High-Performance Inks

The ingredients used in gravure ink are carefully selected to achieve optimal printing results, enhancing print quality and durability. Qinghe Chemical's focus on creating high-performance inks means their products consistently outperform traditional alternatives, providing superior color vibrancy, adhesion, and resistance properties. They have established themselves as leaders in delivering gravure ink solutions that exceed expectations by utilizing top-quality ingredients.

Meeting Industry Standards and Regulations

In an industry where quality control is paramount, meeting industry standards and regulations is non-negotiable. Qinghe Chemical's meticulous approach to ingredient selection ensures that their gravure inks meet and exceed these requirements. Their unwavering commitment to producing safe and compliant products gives customers peace of mind, knowing they are investing in gravure ink solutions that adhere to the highest standards.

The Future of Gravure Ink Solutions

Meeting the Evolving Needs of the Printing Industry

As the printing industry continues to evolve, gravure ink solutions must adapt to meet the changing demands of customers. With technological advancements and consumer preferences, gravure ink formulations must be versatile and customizable to cater to a wide range of printing applications.

Sustainable Innovation in Ink Technology

The future of gravure ink solutions lies in sustainable innovation, focusing on reducing environmental impact while maintaining high-quality printing results. Companies like Qinghe Chemical are at the forefront of developing eco-friendly ink technologies that prioritize performance without compromising sustainability.

Embracing the Shift Towards Eco-Friendly Practices

With increasing awareness about environmental conservation, there is a growing shift towards eco-friendly practices in the printing industry. Water-based gravure inks are becoming increasingly popular due to their low VOC emissions and environmental compatibility, making them a preferred choice for businesses looking to reduce their carbon footprint.

Choose Qinghe Chemical for Your Gravure Ink Needs

Qinghe Chemical is the top choice for all your gravure ink needs. With our expertise in water-based gravure ink formulations and commitment to sustainability, we provide superior solutions for the printing industry. Our innovative approach to gravure ink viscosity and formulation ensures optimal printing results, enhancing print quality and meeting industry standards.

When it comes to gravure printing ink, Qinghe Chemical stands out as a leader in the industry. Our water-based gravure ink solutions offer low VOC emissions, improved work safety, and environmental compatibility. With our customized formulations for different applications, we are dedicated to providing high-performance inks that meet your specific needs.

The Impact of Water-Based Solutions on Your Business

By choosing water-based gravure ink from Qinghe Chemical, you can significantly positively impact your business. Our sustainable ink solutions reduce environmental impact and meet consumer demand for eco-friendly packaging. Embracing this shift towards eco-friendly practices will set your business apart and contribute to a greener future.

Advantages of Sustainable Gravure Ink Solutions

The advantages of sustainable gravure ink solutions cannot be overstated. With our innovative formulations and commitment to reducing environmental impact, you can trust that Qinghe Chemical's products will meet the evolving needs of the printing industry. By choosing our water-based solutions, you invest in high-quality, environmentally friendly products that will benefit your business and the planet.