Introduction

Flexographic printing ink has come a long way in its evolution from traditional solvent-based formulations to the environmentally friendly water-based options available today. The environmental impact of conventional flexographic inks has raised concerns, leading to a shift towards sustainable solutions in the industry. This has paved the way for the widespread adoption of water-based flexographic inks, offering numerous advantages over their solvent-based counterparts.

The Evolution of Flexographic Printing Ink

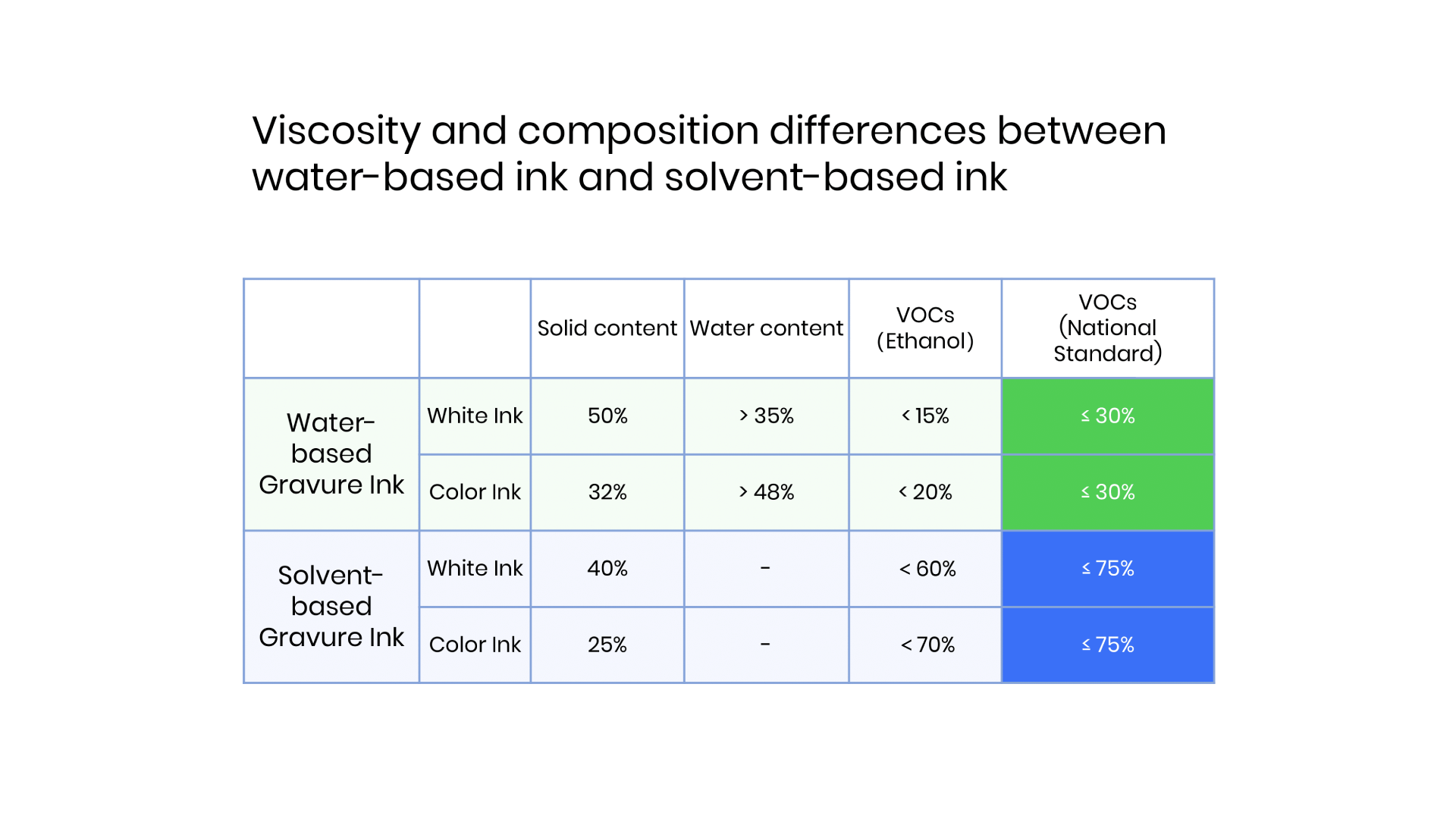

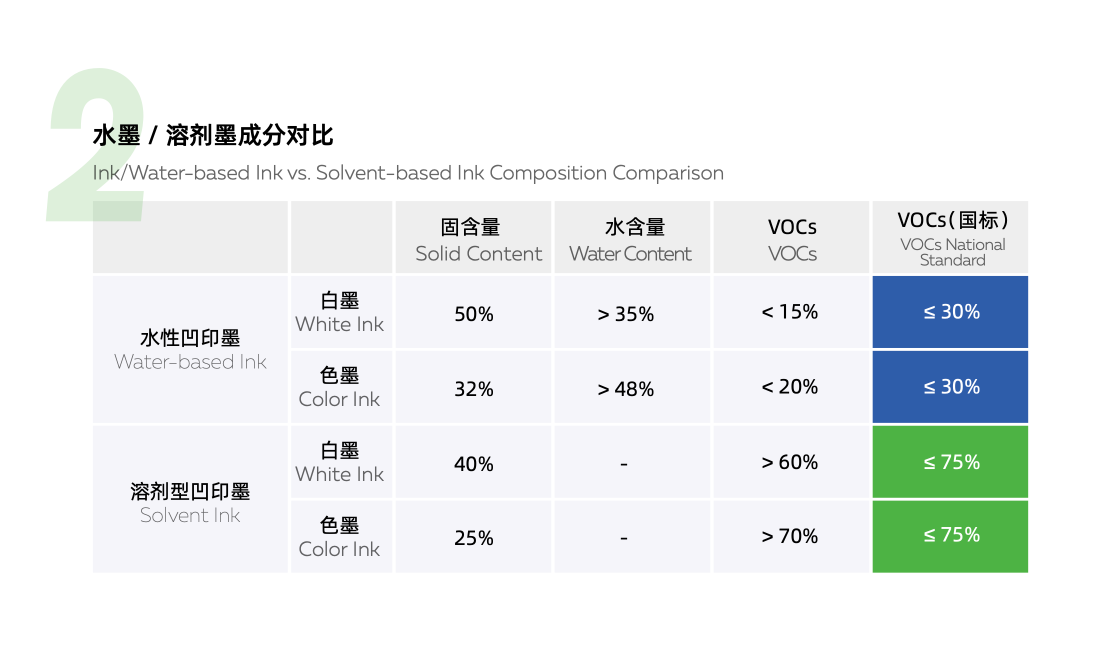

The evolution of flexographic ink can be traced back to its early days when solvent-based formulations were predominantly used. These inks contained high levels of volatile organic compounds (VOCs), posing a significant environmental threat. However, technological advancements have led to the development of water-based flexographic inks, revolutionizing the industry by offering a more sustainable and eco-friendly alternative.

The Environmental Impact of Flexographic Inks

Flexographic printing is popular, but traditional inks can harm the environment. Here's why eco-friendly options are gaining traction:

- Environmental Concerns: Conventional flexo inks are often high in VOCs (volatile organic compounds), contributing to air pollution.

- Sustainability Demands: As environmental awareness rises, consumers and businesses seek eco-friendly packaging and printing solutions.

- Greener Alternatives: The need for sustainable practices is driving the development of eco-friendly flexo inks that minimize environmental impact while delivering high-quality printing.

The demand for eco-friendly flexographic inks responds to environmental concerns and the growing need for sustainable practices throughout various industries.

The Advantages of Water-Based Flexographic Inks

Water-based flexographic inks are revolutionizing the printing industry with environmental and safety benefits. Here's why they're gaining traction:

- Reduced Environmental Impact: Water-based inks contain minimal VOCs (Volatile Organic Compounds), significantly lowering air pollution and promoting a greener printing process.

- Exceptional Print Quality: These inks deliver vibrant colors, sharp images, and excellent performance on various substrates, ensuring high-quality prints.

- Enhanced Worker Safety: The absence of harmful solvents minimizes health risks for printers, creating a safer and more comfortable work environment.

- Consumer-Friendly: Water-based inks are often safer for direct and indirect food contact, making them ideal for food packaging and appealing to sustainability-conscious consumers.

- Regulatory Compliance: As regulations on VOC emissions tighten, water-based inks help businesses comply with evolving environmental standards.

Water-based flexographic inks offer a compelling combination of environmental responsibility, print quality, and worker safety, making them a sustainable and future-proof solution for the flexographic printing industry.

Cost-Effectiveness

Flexographic printing ink is a cost-effective solution for printers and converters, especially regarding safety measures. Unlike solvent-based inks, water-based flexographic inks do not pose health risks to workers, reducing the need for extensive safety precautions and protective gear.

Reduced Need for Safety Measures

With water-based flexographic inks, the need for safety measures such as ventilation systems and fire precautions is significantly reduced. This saves on operational costs and creates a safer working environment for employees.

Lower VOC Emissions

One key cost-saving benefit of water-based flexographic inks is the lower emission of volatile organic compounds (VOCs). This reduces environmental impact and eliminates the need for costly air pollution control equipment and compliance measures.

Elimination of Costly Exhaust Air Treatment

Water-based flexographic inks, printers, and converters can eliminate the need for expensive exhaust air treatment systems required by solvent-based inks. This results in substantial cost savings and contributes to a more sustainable printing process.

Environmental Friendliness

Reduced Impact on the Environment

Water-based flexographic inks have significantly reduced the environmental impact of printing, as they contain lower levels of volatile organic compounds (VOCs) and hazardous air pollutants. This means less air pollution and a smaller carbon footprint, making them a more sustainable choice for eco-conscious businesses looking to minimize their environmental impact.

Healthier Work Environment

The shift towards water-based flexographic inks has also led to a healthier work environment for printing industry professionals. Reduced exposure to harmful chemicals and fumes allows workers to breathe easier and enjoy improved indoor air quality, improving overall health and well-being.

Sustainable Packaging Solutions

One of the most exciting aspects of water-based flexographic inks is their role in driving sustainable packaging solutions. These eco-friendly inks are instrumental in creating recyclable and compostable packaging materials, aligning with consumer demand for environmentally responsible products that minimize waste and pollution.

Versatility and Compatibility

Flexographic printing ink is known for its versatility, making it suitable for a wide range of applications in the packaging industry. Whether for corrugated boxes, flexible packaging, labels, or bags, flexo ink suppliers offer solutions catering to various printing needs.

Wide Range of Applications

From food and beverage packaging to pharmaceutical labels, flexographic inks are designed to meet the diverse demands of different industries. With advancements in technology and formulation, these inks can now deliver high-quality prints on various substrates, including paper, film, and non-porous materials.

Compatibility with Different Substrates

Flexo ink suppliers have developed formulations that ensure compatibility with different substrates, allowing for seamless printing on various materials. This compatibility factor contributes to the widespread adoption of flexographic ink in the packaging industry.

Enhanced Productivity and Efficiency

Flexographic inks' adaptability translates to enhanced productivity and efficiency on the production line. Printers and converters can rely on these inks to deliver consistent results while streamlining their operations for optimal output.

Now, let's explore how the environmental friendliness of water-based flexographic inks contributes to sustainable packaging solutions.

Quality and Performance

Water-based flexographic inks have revolutionized the printing industry by offering high print quality that rivals solvent-based inks. The advanced formulation of these inks ensures sharp, vibrant, and detailed prints, making them ideal for a wide range of packaging applications. Whether it's intricate designs or bold graphics, water-based flexographic inks deliver exceptional print quality that meets the demands of today's market.

High Print Quality

With water-based flexographic inks, printers and converters can achieve superior print quality that enhances the visual appeal of packaging materials. These inks provide excellent color saturation and definition, creating stunning visuals that captivate consumers' attention on retail shelves. By utilizing cutting-edge technology and premium raw materials, flexo ink suppliers can produce high-quality inks that elevate the overall printing standards.

Consistent Color Reproduction

One key advantage of water-based flexographic inks is their ability to reproduce colors consistently with precision and accuracy. This ensures brand consistency across various packaging materials, maintaining the integrity of logos, brand colors, and product imagery. Whether a vibrant red or a subtle pastel shade, these inks deliver consistent color reproduction that aligns with brand guidelines and customer expectations.

Improved Print Durability

In addition to exceptional print quality and color consistency, water-based flexographic inks offer improved durability for packaging materials. The robust nature of these inks results in enhanced resistance to abrasion, scuffing, and fading over time. Printed packaging maintains its visual appeal throughout the supply chain and on store shelves, contributing to a positive consumer experience with the product.

Regulatory Compliance

In today's printing industry, regulatory compliance regarding flexographic printing ink is crucial. Flexo ink suppliers must ensure their products meet safety and environmental standards to protect workers and the environment. By using water-based flexographic inks, companies can reduce harmful emissions and ensure compliance with stringent regulations.

Meeting Safety and Environmental Standards

Water-based flexographic inks are vital in meeting safety and environmental standards within the printing industry. With lower levels of volatile organic compounds (VOCs), these inks contribute to a healthier work environment while minimizing their impact on the planet. Companies can demonstrate their commitment to responsible manufacturing practices by choosing water-based flexo ink.

Compliance with Food Packaging Regulations

Compliance with regulations is non-negotiable when it comes to food packaging. Water-based flexographic inks are ideal for food packaging applications due to their low migration potential and compatibility with food-contact materials. This ensures that packaging printers meet strict food safety regulations while delivering vibrant, high-quality prints for consumer products.

Assurance of Product Quality and Safety

The use of water-based flexographic inks assures product quality and safety throughout the entire printing process. These inks offer excellent adhesion, color strength, and printability while meeting stringent performance requirements for various substrates. By choosing water-based solutions, printers can confidently deliver high-quality, safe products to their customers.

Remember that regulatory compliance isn't just about following rules - it's about ensuring the well-being of workers, protecting the environment, and delivering safe products to consumers!

Innovation and Technology

In the ever-evolving world of flexographic printing ink, continuous development and improvement are key to staying ahead. As technology advances, so do the capabilities of flexo ink suppliers, leading to more efficient and sustainable practices. The future of flexographic ink lies in the hands of innovators committed to pushing the boundaries of what is possible in the packaging flexo industry.

Continuous Development and Improvement

Flexographic ink manufacturers constantly strive to enhance their products through research and development—this dedication to improvement results in inks that offer better print quality, durability, and environmental friendliness. By staying at the forefront of technological advancements, these suppliers ensure that their products meet the ever-changing needs of the printing industry.

Adoption of Sustainable Practices

As environmental concerns shape consumer demands, flexo ink suppliers are embracing sustainable practices in their manufacturing processes. From using renewable resources to reducing waste and emissions, these companies are committed to minimizing their environmental impact while delivering high-quality flexographic inks. This shift towards sustainability benefits the planet and positions these suppliers as leaders in eco-friendly solutions.

The Future of Flexographic Printing Ink

The future of flexographic printing ink is undoubtedly bright, with ongoing innovations driving the industry forward. As more suppliers adopt sustainable practices and develop eco-friendly products, the landscape of packaging flexo will continue to evolve. With a focus on meeting both environmental standards and customer demands for high-quality printing solutions, water-based flexographic inks are poised to lead the way into a more sustainable future.

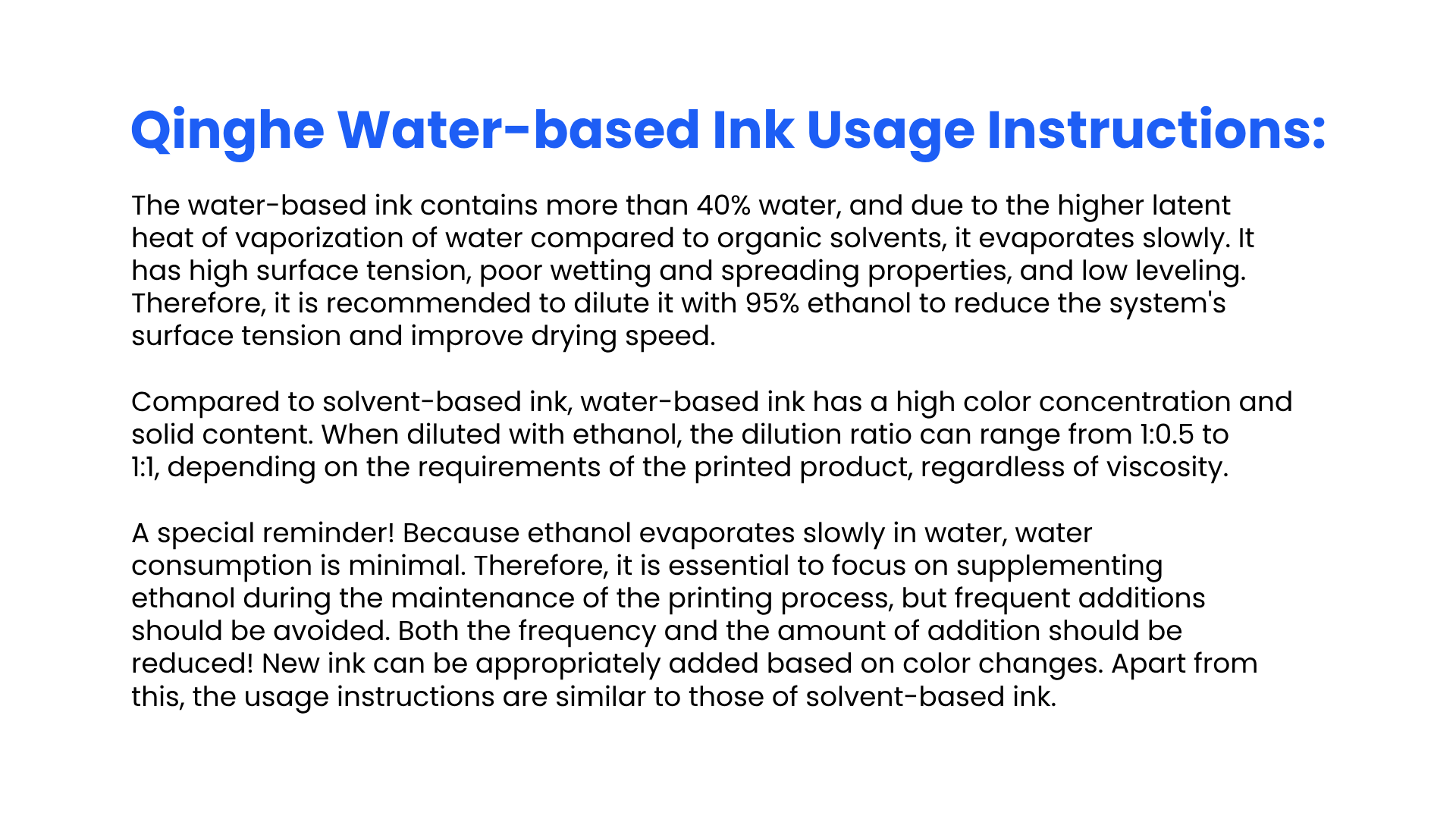

Qinghe Chemical's Contribution

Leading Supplier of Water-Based Flexographic Inks

Qinghe Chemical has established itself as a leading supplier of water-based flexographic inks, offering a wide range of high-quality products tailored to meet the diverse needs of the printing industry. With a strong focus on innovation and customer satisfaction, Qinghe Chemical continues to set the standard for excellence in the flexo ink market.

Commitment to Environmental Sustainability

Qinghe Chemical has invested heavily in research and development to create eco-friendly flexographic inks that minimize environmental impact without compromising on performance. As part of its commitment to environmental sustainability, the company prioritizes sustainability to lead by example and inspire positive change within the industry.

Advancing the Flexo Ink Industry

Qinghe Chemical is at the forefront of advancing the flexo ink industry through continuous investment in technology and expertise. By pushing boundaries and challenging conventional practices, the company drives innovation and sets new benchmarks for quality, performance, and environmental responsibility.

Industry Impact

The shift towards sustainable solutions in the flexographic printing ink industry is undeniable. With increasing awareness of environmental concerns, more and more flexo ink suppliers are embracing eco-friendly practices to meet the demand for sustainable packaging solutions. This shift is not just a trend; it's a fundamental change in how the industry operates, driven by the need to minimize environmental impact and reduce carbon footprint.

Shifting Towards Sustainable Solutions

Flexographic ink manufacturers are transitioning towards water-based flexographic inks, significantly reducing VOC emissions and minimizing environmental harm. This move aligns with the global push for sustainability as companies seek to adopt responsible practices that benefit their operations and the planet. Adopting sustainable solutions is not just a choice; it's becoming an industry standard that sets the bar for responsible manufacturing practices.

Influence on Packaging Flexo

The influence of sustainable flexographic inks is particularly evident in packaging flexo, where brands increasingly prioritize eco-friendly materials and processes. As consumer preferences shift towards environmentally conscious products, packaging manufacturers must adapt their printing methods accordingly. This influence has led to a surge in demand for water-based flexo ink suppliers who can provide high-quality, sustainable solutions for packaging needs.

Driving Change in the Printing Industry

The impact of water-based flexographic inks extends beyond just one printing industry segment; it's driving change across the board. From labels and flexible packaging to corrugated boxes and folding cartons, there's a growing demand for sustainable printing solutions that meet regulatory standards while delivering exceptional quality. This shift reshapes the printing landscape, compelling printers and converters to embrace eco-friendly practices catering to evolving consumer expectations.

Customer Benefits

Cost Savings for Printers and Converters

Water-based flexographic inks offer significant cost savings for printers and converters. Production costs are lowered with reduced need for safety measures and costly exhaust air treatment, resulting in higher profit margins. Additionally, lower VOC emissions mean less investment in pollution control equipment, further contributing to cost-effectiveness.

Enhanced Brand Image and Reputation

Printers and converters can enhance their brand image and reputation using sustainable water-based flexographic inks. Consumers are increasingly conscious of environmental impact, and by using eco-friendly packaging solutions, companies can position themselves as responsible and environmentally aware businesses, attracting more customers and building brand loyalty.

Meeting Consumer Demand for Eco-Friendly Packaging

In today's market, consumers demand eco-friendly packaging solutions, driving the need for sustainable practices in the printing industry. Water-based flexographic inks allow printers and converters to meet this demand by offering environmentally friendly packaging options that align with consumer values and preferences.

Future Outlook

As the demand for sustainable printing solutions grows, the future outlook for water-based flexographic inks is promising. With advancements in technology and increased awareness of environmental impact, the market for these eco-friendly inks is expected to expand significantly. Printers and converters recognize the benefits of water-based flexo inks, driving the growth and adoption of these innovative products.

Growth of Water-Based Flexographic Inks

The shift towards environmentally friendly printing practices fueled the growth of water-based flexographic inks. As more companies prioritize sustainability, there is a clear trend toward replacing traditional solvent-based inks with water-based alternatives. This transition meets regulatory standards and aligns with consumer preferences for eco-conscious packaging solutions. The continued development and improvement of water-based flexo inks will further drive their growth in the printing industry.

Expansion of Flexo Ink Suppliers

With the increasing demand for water-based flexographic inks, there is a corresponding expansion of suppliers offering these sustainable products. The competition among flexo ink suppliers has led to incredible innovation and product diversity, providing printers and converters with a broader range of options to meet their specific needs. This expansion also contributes to market growth by making eco-friendly printing solutions more accessible and affordable for businesses across various industries.

Embracing Sustainable Practices in Printing

The flexographic printing industry is transforming sustainable practices. This goes beyond just the inks used but encompasses a holistic approach to minimizing environmental impact:

- Sustainable Inks: A shift towards water-based, soy/vegetable, UV, and algae-based inks reduces reliance on solvent-based options and minimizes harmful VOC emissions.

- Recyclable Substrates: Choosing printing materials that can be easily recycled after use promotes a circular economy and reduces waste.

- Energy-Efficient Production: Implementing practices like optimized drying processes and energy-saving equipment reduces the industry's carbon footprint.

By embracing these sustainable practices, flexographic printers can meet consumer demand for eco-friendly packaging and contribute to a more responsible future for the industry.

The Future of Flexographic Printing Ink

The future of flexographic printing ink looks promising, with the increasing demand for sustainable and eco-friendly solutions. As more flexo ink suppliers embrace water-based flexographic inks, the industry is shifting towards a more environmentally conscious approach. This shift is driving change in packaging flexo and influencing the printing industry.

The future of flexographic printing ink lies in developing and adopting water-based inks that offer cost-effective, environmentally friendly, and high-quality solutions. With advancements in technology and innovation, the growth of water-based flexographic inks is inevitable, leading to a more sustainable and eco-friendly printing industry.

Making the Switch to Water-Based Inks

As the industry continues to prioritize sustainability, switching to water-based flexographic inks is not just a trend but a necessity. Printers and converters can benefit from cost savings while enhancing their brand image by embracing eco-friendly solutions that meet consumer demand for sustainable packaging.

Embracing Sustainability in Printing

Embracing sustainability in printing means adopting practices that reduce environmental impact without compromising quality or performance. By choosing water-based flexographic inks, printers can contribute to a healthier environment while meeting regulatory compliance and driving positive change within the industry.