Introduction

Are you seeking a sustainable and efficient solution for your packaging ink needs? Look no further than Qinghe's Waterborne Polyurethane Inks. With the rise of environmental consciousness, polyurethane water-based ink has become the go-to choice for packaging industry professionals. Its versatility and durability make it a top contender in the market.

Why Choose Qinghe's Waterborne Polyurethane Inks?

Qinghe's waterborne polyurethane ink stands out for its eco-friendly composition, making it an ideal choice for businesses looking to reduce their environmental impact. Using water-soluble polyurethane and polyurethane resin for gravure ink ensures a sustainable and non-toxic solution that meets regulatory standards while delivering exceptional performance.

Benefits of Using Polyurethane Water-Based Ink for Packaging

Polyurethane water-based ink is a valuable asset for the packaging industry due to its numerous advantages. Here are some key benefits:

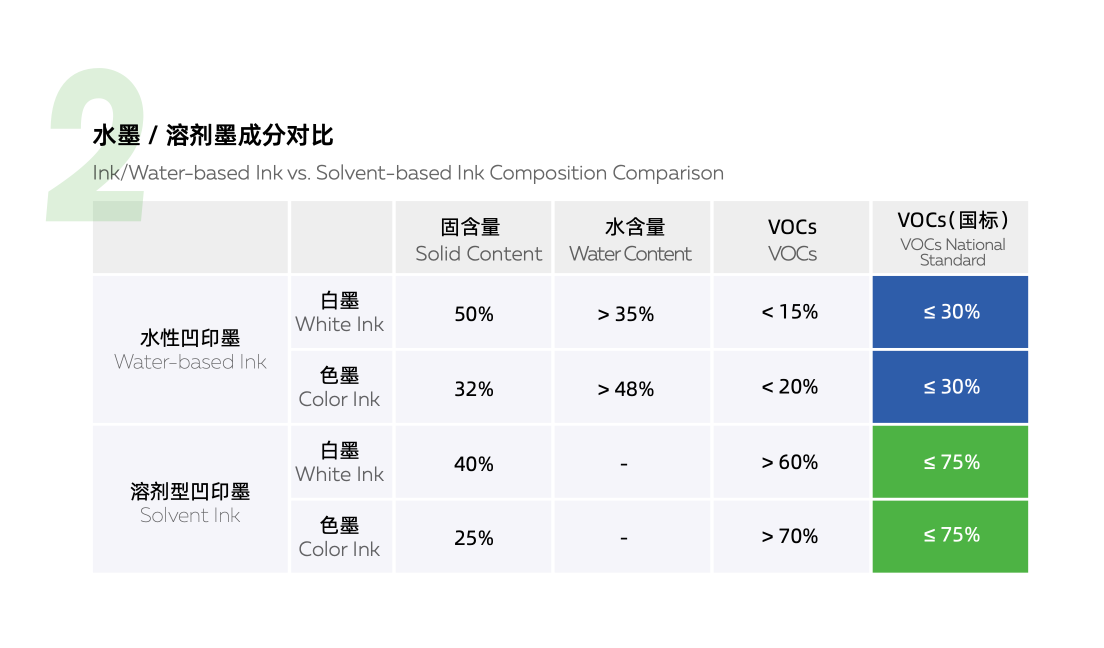

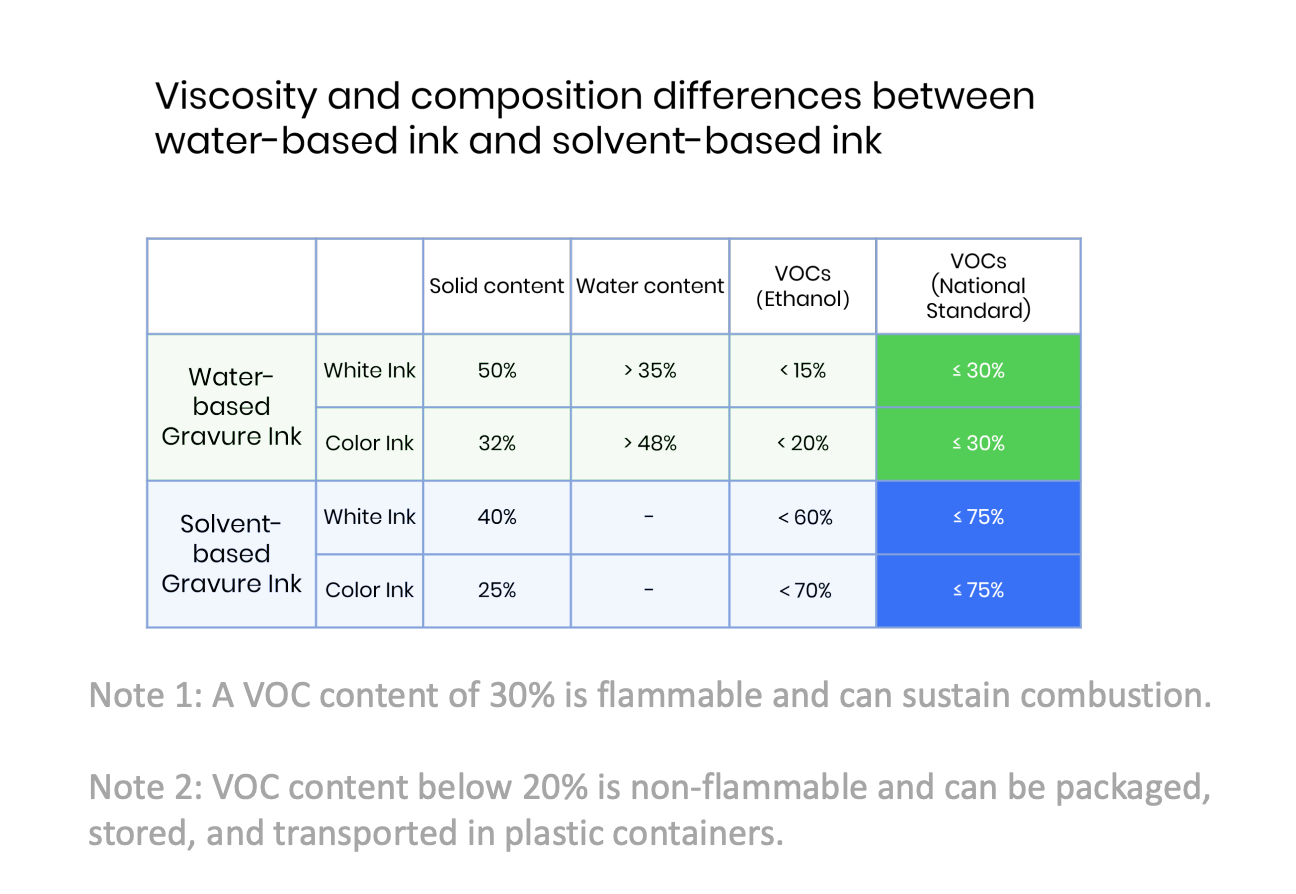

- Reduced VOC Emissions: This type of ink is environmentally friendly as it significantly lowers the emission of volatile organic compounds (VOCs), contributing to cleaner air and a healthier environment.

- Enhanced Durability: Polyurethane water-based ink provides exceptional durability, ensuring that packaging maintains its visual appeal and integrity over time. It resists abrasion, wear, and fading, making it ideal for products with long shelf lives.

- Cost-Effective Solutions: While the initial investment in polyurethane water-based ink might be slightly higher, it offers long-term cost savings. Its durability and resistance to fading reduce the need for frequent reprints or replacements, ultimately optimizing packaging costs.

- Versatility in Application: This type of ink is compatible with various printing methods and substrates, making it adaptable to different packaging needs. It can be used on various materials, including paper, cardboard, and plastic films.

In conclusion, polyurethane water-based ink is a valuable choice for packaging that prioritizes environmental sustainability, durability, cost-efficiency, and versatility. By adopting this innovative ink technology, businesses can enhance their packaging while contributing to a healthier planet.

The Rise of Polyurethane Water-Based Ink in the Packaging Industry

As consumer demand for sustainable packaging grows, so does the popularity of polyurethane water-based ink. Its ability to adapt to various printing methods and meet different design requirements makes it a valuable asset in the ever-evolving world of packaging. Embracing this innovative solution is key to staying ahead in the industry. Furthermore, polyurethane water-based ink offers excellent adhesion to a wide range of substrates, including paper, cardboard, and flexible films, providing versatility for packaging manufacturers. This flexibility allows for greater creativity in design and branding, helping products stand out on the shelf and attract consumer attention.

Environmentally Friendly

Polyurethane water-based inks offer a sustainable packaging solution that reduces VOC emissions, making them an eco-friendly choice for the packaging industry. By utilizing water as a solvent instead of traditional polyurethane solvents, these inks significantly decrease the release of harmful volatile organic compounds into the atmosphere.

Reducing VOC Emissions

With polyurethane water-based inks, traditional polyurethane solvents are eliminated, drastically reducing VOC emissions. This environmentally friendly alternative helps minimize air pollution and contributes to a healthier working environment for packaging professionals.

By using polyurethane water-based inks, packaging professionals can also enjoy the added benefit of improved workplace safety. With traditional polyurethane solvents eliminated, the risk of exposure to harmful chemicals is greatly reduced, creating a safer and more comfortable environment for employees. This benefits workers' health and well-being and increases productivity and efficiency in packaging operations.

Sustainable Packaging Solution

The shift towards waterborne polyurethane inks represents a significant step in creating sustainable packaging solutions. By reducing environmental impact and promoting responsible resource management, these innovative inks align with the growing demand for eco-friendly packaging materials.

Furthermore, using waterborne polyurethane inks also offers practical benefits for packaging manufacturers. These inks are known for their fast drying time, which can lead to increased production efficiency and reduced energy consumption. Additionally, their high adhesion properties contribute to the overall durability and quality of the packaging, ensuring that products are well-protected during transportation and storage.

Meeting Regulatory Standards

Polyurethane water-based inks meet stringent regulatory standards by complying with environmental protection regulations and emission control requirements. This ensures that packaging manufacturers can uphold their commitment to sustainability while adhering to industry regulations.

Polyurethane water-based inks also offer enhanced durability, ensuring that packaging maintains its integrity throughout the supply chain and on the retail shelf. This longevity reduces the need for reprints and replacements, ultimately decreasing waste and supporting sustainable practices. Packaging manufacturers can demonstrate their commitment to environmental responsibility and product quality by choosing these inks.

Enhanced Durability

Durability is key in packaging, and that's where polyurethane water-based ink shines. With its unique formulation, polyurethane ink offers exceptional resistance to abrasion and wear, ensuring that your packaging maintains its pristine appearance throughout its lifecycle.

Resisting Abrasion and Wear

Polyurethane water-based ink is formulated with polyurethane resin for gravure ink, providing outstanding abrasion and wear resistance. Your packaging will remain intact and visually appealing, even in high-traffic environments or during rough handling.

Polyurethane water-based ink resists abrasion and wear and offers excellent color retention over time. This means your packaging will maintain its vibrant and eye-catching appearance, even after prolonged exposure to sunlight and other environmental factors. Your brand's colors will stay true and impactful, ensuring your product stands out.

Long-Lasting Colors

Thanks to using polyurethane microspheres in the formulation of waterborne polyurethane ink, the colors maintain their vibrancy and integrity over time. This ensures that your packaging continues to make a lasting impression on consumers, helping to reinforce brand recognition and loyalty.

Additionally, waterborne polyurethane ink makes it suitable for various packaging materials, including cardboard, paper, and plastic. This versatility allows for consistent color performance across different substrates, ensuring that your brand's packaging maintains a high-quality appearance no matter the material used. This adaptability also saves costs by eliminating the need for separate inks for different packaging materials.

Suitable for Various Packaging Materials

Polyurethane water-based ink offers excellent adhesion and flexibility when working with paper, cardboard, plastic, or other materials. This versatility makes it ideal for various packaging applications, providing consistent performance across different substrates.

Cost-Effective Solution

Polyurethane water-based inks offer a cost-effective solution for packaging companies. Businesses can improve production efficiency and reduce operational costs by using polyurethane resin for gravure ink. The water-soluble polyurethane lowers maintenance expenses and minimizes waste, making it an economical choice for sustainable packaging.

Improving Production Efficiency

Polyurethane water-based inks, such as waterborne polyurethane, are known for enhancing production efficiency. Using polyurethane solvent inks ensures smooth printing processes, resulting in higher output and reduced downtime. This ultimately leads to cost savings and improved overall productivity for packaging manufacturers.

Lower Maintenance Costs

With the polyurethane microspheres in the market, companies can significantly lower maintenance costs associated with printing equipment. The durable nature of polyurethane water-based inks reduces wear and tear on machinery, extending its lifespan and minimizing the need for frequent repairs or replacements. This translates to substantial savings for businesses in the long run.

With polyurethane microspheres in the market, companies can lower maintenance costs and minimize waste associated with printing equipment. The innovative technology of polyurethane water-based inks reduces the amount of ink and solvent waste produced during the printing process, leading to a more eco-friendly and sustainable operation. This benefits the environment and saves businesses money by reducing the need for costly waste disposal methods.

Minimizing Waste

Polyurethane water-based inks are designed to minimize waste during the packaging production process. Their high-quality formulation ensures optimal adhesion and coverage, reducing the likelihood of misprints or rework due to poor ink performance. This saves material costs and contributes to a more sustainable and environmentally friendly operation.

Polyurethane water-based inks also offer faster drying times compared to traditional solvent-based inks. This means that packaging can move through the production process more quickly, reducing the overall lead time and increasing efficiency. Additionally, the fast-drying nature of these inks minimizes the risk of smudging or smearing during handling and transportation, ensuring that your packaging arrives at its destination looking pristine and professional.

Now you understand why choosing polyurethane water-based inks for your packaging needs is a smart move!

Versatility in Application

Polyurethane water-based ink is a game-changer in packaging. It is ideal for different packaging materials, such as paper, cardboard, and plastic. Whether for food, cosmetics, or pharmaceuticals, this ink provides exceptional adhesion and flexibility to cater to various packaging needs.

Ideal for Different Types of Packaging

Qinghe's waterborne polyurethane ink offers a versatile solution for diverse packaging needs. Its exceptional properties make it suitable for a wide range of applications.

- Adheres to Various Surfaces: Qinghe's ink ensures strong adhesion to flexible films, rigid containers, and corrugated boxes, guaranteeing long-lasting and vibrant packaging.

- Excellent Durability: The ink's durability protects your packaging from scratches, scuffs, and fading, maintaining its pristine appearance.

- Environmentally Friendly: Waterborne polyurethane ink is a more eco-conscious choice compared to traditional solvent-based inks, reducing environmental impact.

- Quick-Drying Technology: This ink's rapid drying time enhances production efficiency and minimizes downtime.

- Superior Color Retention: Qinghe's ink delivers exceptional color accuracy and brightness, ensuring your packaging stands out with vibrant visuals.

By choosing Qinghe's waterborne polyurethane ink, you're investing in a reliable, high-performance solution that will elevate your packaging and leave a lasting impression on your customers.

Adaptable to Various Printing Methods

One remarkable feature of polyurethane water-based ink is its adaptability to various printing methods, such as flexography, gravure printing, and digital printing. This makes it suitable for different production processes while maintaining excellent color consistency and print quality across all platforms.

Meeting Different Design Requirements

Waterborne polyurethane ink offers many options to meet diverse design requirements, whether you need high-gloss finishes, matte effects, or special textures for your packaging design. Its ability to create vibrant colors and intricate designs makes it a top choice for brands looking to stand out on the shelves.

By choosing Qinghe's waterborne polyurethane inks, brands can elevate their packaging game with versatile solutions that cater to different materials and design needs while maintaining environmental sustainability.

Improved Safety and Health Standards

Polyurethane water-based inks are non-toxic and non-hazardous, making them a safe choice for packaging applications. Unlike traditional solvent-based inks, polyurethane water-based inks do not contain harmful chemicals or emit toxic fumes during printing, ensuring a healthier working environment for employees.

Non-Toxic and Non-Hazardous

With the increasing focus on safety and health standards in the packaging industry, polyurethane water-based inks offer a non-toxic and non-hazardous alternative to traditional solvent-based inks. This makes them an ideal choice for companies looking to prioritize the well-being of their employees while maintaining high-quality printing standards.

Polyurethane water-based inks also benefit from being environmentally friendly, as they produce fewer volatile organic compounds (VOCs) than solvent-based inks. This contributes to a healthier work environment for employees and aligns with corporate sustainability goals. Companies can demonstrate their commitment to reducing their environmental footprint and promoting a greener approach to packaging production by choosing non-toxic and non-hazardous inks.

Ensuring Consumer Safety

Polyurethane water-based inks are safe for workers and ensure consumer safety by eliminating the risk of harmful chemical residues leaching into packaged products. This is particularly important for food and beverage packaging, where stringent safety regulations require ink materials to be free from toxic substances.

Furthermore, polyurethane water-based inks offer a user-friendly and easy-to-handle solution for packaging companies. Unlike solvent-based inks, requiring special ventilation and handling precautions, water-based inks are much safer and more convenient. This reduces the risk of accidents or exposure for workers and streamlines the production process, making it more efficient.

User-Friendly and Easy to Handle

Polyurethane water-based inks are user-friendly and easy to handle, reducing the risk of accidents or mishaps during the printing process. Their water-soluble nature also simplifies clean-up procedures, enhancing workplace safety by minimizing exposure to potentially hazardous cleaning solvents.

Polyurethane water-based inks offer ease of use, safety benefits, excellent color vibrancy, and print quality. This means that users can enjoy the convenience of working with a user-friendly ink while still achieving professional results. The ability to produce high-quality prints without compromising safety or ease of use makes these inks valuable for any printing operation.

Future of Sustainable Packaging

In conclusion, switching to polyurethane water-based ink is a smart choice for businesses prioritizing sustainability and efficiency in their packaging processes. With the rise of sustainable packaging solutions, the future looks bright for those embracing polyurethane water-based inks. Qinghe's waterborne polyurethane inks offer a reliable and eco-friendly option for businesses seeking to reduce their environmental impact while maintaining high-quality packaging standards.

Making the Switch to Polyurethane Water-Based Ink

By choosing polyurethane water-based ink, businesses can significantly reduce VOC emissions and contribute to a more sustainable future. Using water-soluble polyurethane resin for gravure ink also ensures compliance with regulatory standards, promoting a safer working environment and healthier communities.

The future of sustainable packaging is promising, with an increasing demand for eco-friendly solutions catering to consumer preferences and environmental concerns. As businesses continue to prioritize sustainability, the adoption of polyurethane water-based inks will play a crucial role in shaping this future.

Embracing Qinghe's Waterborne Polyurethane Inks

Embracing Qinghe's waterborne polyurethane inks means investing in a versatile and cost-effective solution that offers enhanced durability, improved safety standards, and versatility in application. The polyurethane solvent and microspheres market further solidifies its position as an innovative and forward-thinking choice for businesses seeking sustainable packaging alternatives.