Introduction

Are you seeking a more sustainable and cost-effective option for your screen printing projects? Look no further than water-based screen printing inks. These inks offer a range of benefits, from environmental advantages to superior print quality. This guide will explore why water-based inks are the way for your printing needs.

The Environmental Benefits

Water-based inks offer a more sustainable and eco-friendly alternative to traditional inks. Here are some of the key environmental benefits of switching to water-based inks:

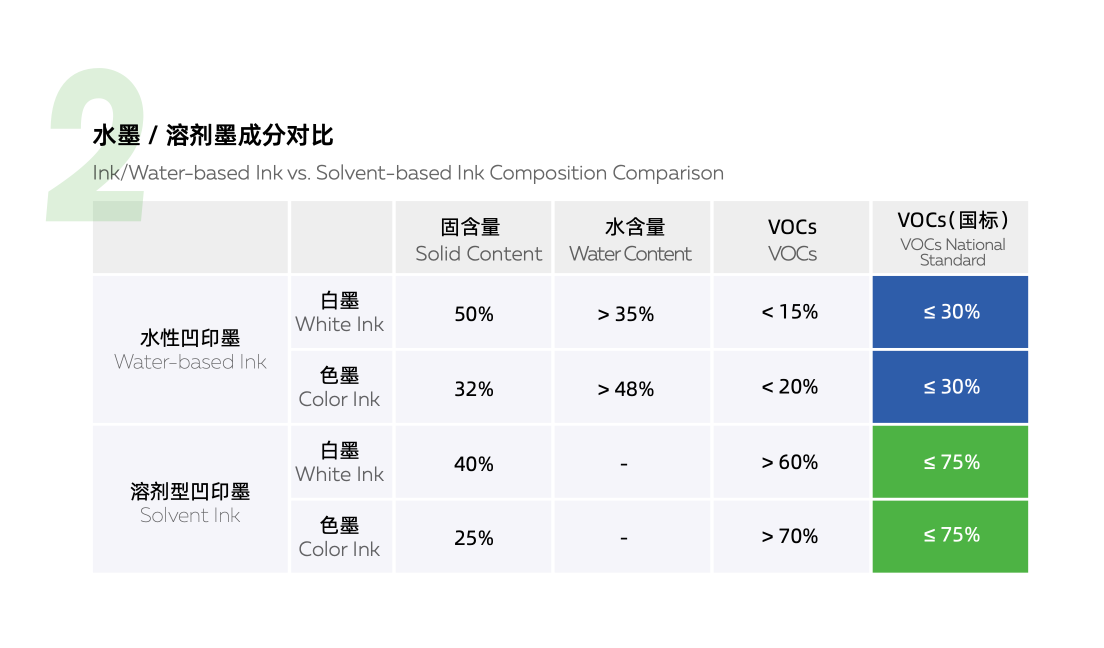

- Reduced Air Pollution: Water-based inks eliminate volatile organic compounds (VOCs) from the printing process. VOCs contribute to smog and other air quality problems, so reducing them helps create a healthier environment.

- Improved Worker and Consumer Health: Since water-based inks don't contain harmful solvents, they pose less of a health risk to workers who handle them and consumers who come into contact with printed materials.

- Lower Carbon Footprint: Water-based inks often rely on sustainable materials and require lower curing temperatures during printing, reducing the carbon footprint.

By choosing water-based inks, printing companies can demonstrate their commitment to environmental responsibility and contribute to a greener future for the industry.

The Cost Savings

In addition to the environmental benefits, using water-based inks can lead to significant cost savings for businesses. Companies can cut operational expenses with reduced need for safety measures such as ventilation and protective gear. Furthermore, the lower production costs of water-based inks make them cost-effective for businesses looking to save money without sacrificing quality. Additionally, the longer equipment lifespan means companies can avoid frequent replacements and repairs, ultimately saving on maintenance and replacement costs in the long run. Switching to water-based inks benefits the environment and offers a practical way for businesses to save money while maintaining high-quality results.

The Versatility

Water-based inks offer a wide range of applications, making them versatile for various printing needs. Water-based inks can provide vibrant and long-lasting prints on different substrates, whether with paper, fabric, or wood. Their custom color mixing capabilities allow endless possibilities for creating unique and eye-catching designs. With water-based inks, you can unleash your creativity without limitations and achieve stunning results across diverse materials.

The Health Benefits

Water-based inks offer a safer work environment for printers and processors, as they do not emit harmful fumes or toxins during printing. This significantly reduces the risk of respiratory and other health problems associated with exposure to volatile organic compounds (VOCs) commonly found in traditional solvent-based inks. By switching to water-based inks, businesses can prioritize their employees' well-being while contributing to a healthier planet. Additionally, the non-toxic formulation of water-based inks means that there is less risk of skin irritation or other adverse health effects for those working with these materials.

The Quality Results

Water-based inks are gaining popularity in the printing industry for a reason. They offer a compelling combination of environmental benefits, cost-effectiveness, and superior print quality.

Here are some key advantages of using water-based inks:

- Environmentally Friendly: Water-based inks are formulated with water as the primary solvent, significantly reducing reliance on harmful chemicals and VOCs (volatile organic compounds) contributing to air pollution.

- Cost-Effective: Water-based inks are generally less expensive than solvent-based inks. Additionally, cleanup with water is more straightforward and less hazardous, leading to further cost savings.

- Superior Print Quality: Water-based inks produce sharp, vibrant prints with exceptional color accuracy and consistency. They also offer excellent detail reproduction, making them ideal for intricate designs.

- Wash Fastness and Durability: Water-based inks excel in wash fastness, ensuring printed colors stay true even after multiple washes. Their superior durability makes them a perfect choice for long-lasting applications.

- Versatility: Water-based inks can be used on various materials, including apparel, signage, and packaging, delivering outstanding quality across diverse printing needs.

With their environmental benefits, cost-efficiency, and exceptional printing capabilities, water-based inks are a sustainable and high-performing solution for many printing applications.

Environmental Benefits

Water-based screen printing inks offer many environmental benefits, making them an attractive printer choice. These inks significantly reduce air pollution and contribute to a healthier work environment by eliminating VOCs. Additionally, their carbon footprint reduction makes them a sustainable option for eco-conscious businesses looking to minimize their environmental impact.

Elimination of VOCs

By using water-based screen printing inks, businesses can eliminate volatile organic compounds (VOCs) from their printing processes. These harmful chemicals are known to affect human health and the environment adversely. By switching to water-based inks, printers can significantly reduce their emissions of VOCs, contributing to cleaner air and safer working conditions. Additionally, water-based inks are easier to clean up and require less energy to cure, further reducing the environmental impact of the printing process. This benefits the planet and helps businesses save on operational costs in the long run.

Reduction of Carbon Footprint

Water-based inks also play a crucial role in reducing the carbon footprint associated with traditional printing processes. By using natural ingredients and renewable resources, these inks help minimize the printing industry's environmental impact. This makes them an ideal choice for businesses adopting more sustainable practices and reducing their overall environmental footprint.

Water-based inks are not only environmentally friendly but also offer high-quality printing results. They can result in vibrant and long-lasting prints, making them a practical choice for businesses that want to reduce their environmental impact without sacrificing the quality of their printed materials. This combination of sustainability and quality makes water-based inks a smart investment for any company looking to make a positive change.

Sustainable Printing Practices

In addition to eliminating VOCs and reducing carbon footprint, water-based screen printing inks promote sustainable printing practices that align with eco-friendly initiatives. Their non-toxic formulation and use of water as a solvent make them an environmentally responsible choice for printers seeking to minimize their ecological impact while delivering high-quality results.

Water-based screen printing inks also offer the advantage of easy cleanup and reduced waste generation. Unlike traditional solvent-based inks, water-based inks can be easily cleaned with water, eliminating the need for harsh chemicals and reducing hazardous waste produced during printing. This contributes to a cleaner and safer work environment and helps printers save on disposal costs associated with hazardous waste.

Cost Savings

Water-based screen printing inks offer significant cost savings for businesses. By using water-based inks, companies can reduce the need for expensive safety measures for handling hazardous chemicals commonly found in traditional solvent-based inks. This means less money spent on protective gear and safety training, ultimately cutting down on operational expenses.

Reduced Need for Safety Measures

With water-based screen printing inks, businesses can say goodbye to costly safety measures typically associated with traditional solvent-based inks. By eliminating the need for unique ventilation systems and protective gear, such as respirators and gloves, companies can save substantial money on safety equipment and compliance with occupational health regulations.

By using water-based screen printing inks, businesses can also reduce the risk of fire hazards in their production facilities. Traditional solvent-based inks are highly flammable, posing a significant danger to workers and the workplace. With water-based inks, companies can minimize the risk of fires and potential damage to their equipment and facilities, ultimately saving on insurance costs and downtime due to accidents.

Lower Production Costs

Another advantage of using water-based inks is the potential for lower production costs. These eco-friendly inks require minimal cleanup and are easily washable with water, reducing the need for expensive cleaning solvents. Water-based inks have a longer shelf life than their solvent-based counterparts, resulting in less waste and lower material costs over time.

Longer Equipment Lifespan

By switching to water-based screen printing inks, businesses can extend the lifespan of their equipment. Unlike solvent-based inks that can be harsh on machinery and cause premature wear and tear, water-based inks are gentler on screens and other printing equipment. This translates to fewer repairs and replacements, saving companies money on maintenance and capital expenditures.

In addition to the cost-saving benefits of using water-based screen printing inks, businesses can also enjoy the environmental advantages. Water-based inks are much more eco-friendly than their solvent-based counterparts, as they contain fewer volatile organic compounds (VOCs) and are easier to clean up. This means that companies can reduce their environmental impact and contribute to a healthier planet while saving money on disposal and regulatory compliance costs.

Versatility

Water-based screen printing inks offer various applications, making them suitable for various industries and purposes. From textiles to packaging, these inks can be used on different materials, providing flexibility and adaptability for any printing project.

Wide Range of Applications

Water-based inks are perfect for printing on textiles such as cotton, polyester, and blends. They are also ideal for paper and cardboard packaging, allowing for vibrant and durable prints on various substrates, whether t-shirts or cardboard boxes; water-based inks deliver exceptional results across different applications.

Compatibility with Different Substrates

One key advantage of water-based screen printing inks is their compatibility with a wide range of substrates. These inks adhere well to different materials, including fabric, paper, cardboard, and wood. This compatibility makes them versatile for printers looking to expand their capabilities and cater to diverse client needs.

Custom Color Mixing Capabilities

Printers can create custom colors with water-based inks by mixing primary ink colors. This feature allows for endless color possibilities and gives printers the freedom to match specific brand colors or create unique shades for their designs. Mixing custom colors adds a creative dimension to the printing process.

Health Benefits

Safer Work Environment

Water-based screen printing inks are a healthier alternative to traditional solvent-based inks, offering several advantages for both printers and the environment. Here are some of the key benefits:

- Improved Air Quality: Water-based inks don't emit hazardous fumes, reducing respiratory risks for printers and processors.

- Safer Handling: The absence of harsh chemicals minimizes the risk of skin irritation and allergic reactions during handling.

- Easier Cleanup: Water-based inks clean up with soap and water, simplifying the cleaning process and reducing exposure to harmful solvents.

Switching to water-based screen printing inks is a smart choice for creating a safer work environment for your employees and a more sustainable printing process.

Reduced Health Risks for Processors

Using water-based inks significantly reduces health risks for processors compared to traditional solvent-based inks. This eco-friendly alternative eliminates the risk of respiratory issues, skin irritation, and other health problems associated with exposure to harmful chemicals commonly found in solvent-based inks.

Non-Toxic Formulation

Water-based screen printing inks are formulated without toxic substances, making them healthier for the environment and human health. The absence of hazardous components ensures that the ink is safe to handle and dispose of, reducing the overall environmental impact.

Quality Results

Water-based screen printing inks are known for delivering sharp and vibrant prints that genuinely stand out. The rich and bold colors give your designs a professional and eye-catching finish. Whether you're working on t-shirts, posters, or any other fabric or material, water-based inks ensure that your prints look top-notch every time.

Sharp and Vibrant Prints

When using water-based screen printing inks, your designs will pop with vivid colors that make a lasting impression. The ink adheres seamlessly to the fabric or material, resulting in crisp and detailed prints that catch the eye. Say goodbye to dull and lackluster results—water-based inks elevate your designs to a whole new level of vibrancy.

Excellent Wash Fastness

One critical advantage of water-based inks is their exceptional wash fastness. Your prints will maintain their brilliance even after multiple washes, ensuring they look as good as new for a long time. This durability is crucial for garments and other printed items that need to withstand regular use and laundering without losing their visual appeal.

Superior Durability

In addition to excellent wash fastness, water-based screen printing inks offer superior durability overall. The prints hold up well against wear and tear, maintaining their quality and integrity over time. This means that your designs will continue to impress customers long after they've been printed, making water-based inks an intelligent choice for businesses looking for long-lasting impact.

A Greener Future with Water-Based Inks

Water-based screen printing inks offer a greener future for the printing industry. These inks pave the way for sustainable printing practices by eliminating harmful VOCs and reducing carbon footprint. With lower production costs and longer equipment lifespan, businesses can save costs and improve safety by switching to water-based inks. Elevate print quality with sharp, vibrant prints, excellent wash fastness, and superior durability using water-based inks.

By choosing water-based screen printing inks, businesses contribute to a greener future by eliminating volatile organic compounds (VOCs) and reducing their carbon footprint. Eco-friendly water-based inks that prioritize environmental conservation achieve sustainable printing practices.

Save Costs and Improve Safety with Water-Based Inks

Water-based screen printing inks not only save costs through reduced need for safety measures but also improve safety for processors by providing a safer work environment with non-toxic formulations. Lower production costs and longer equipment lifespan further contribute to cost savings.

Elevate Print Quality with Water-Based Inks

Experience superior print quality with water-based inks that offer sharp, vibrant prints, excellent wash fastness, and durability that meets industry standards. The versatility of these inks allows for custom color mixing capabilities across a wide range of applications.

Water-based inks are environmentally friendly and non-toxic, making them a safer option for printers and consumers. By choosing water-based inks, you can reduce your carbon footprint and contribute to a more sustainable future for the planet. With increasing demand for eco-friendly products, using water-based inks can also be a selling point for your business, attracting environmentally conscious customers.

Remember to switch to water-based screen printing inks today for a more sustainable future!