Introduction

Qinghe Chemical has emerged as a trailblazer in setting the standard for eco-friendly flexographic printing inks in the dynamic world of printing. Their commitment to innovation has led to the latest advancements in water-based flexographic printing inks, revolutionizing the industry. As businesses and consumers increasingly prioritize sustainability, the demand for eco-friendly and efficient flexographic printing inks continues to grow, making understanding their significance more critical than ever.

Qinghe Chemical: Setting the Standard for Eco-Friendly Printing Inks

Qinghe Chemical has established itself as a leader in producing high-quality, environmentally friendly flexographic printing inks that deliver exceptional results. With a focus on reducing environmental impact without compromising performance, they have set a new benchmark for sustainable ink solutions.

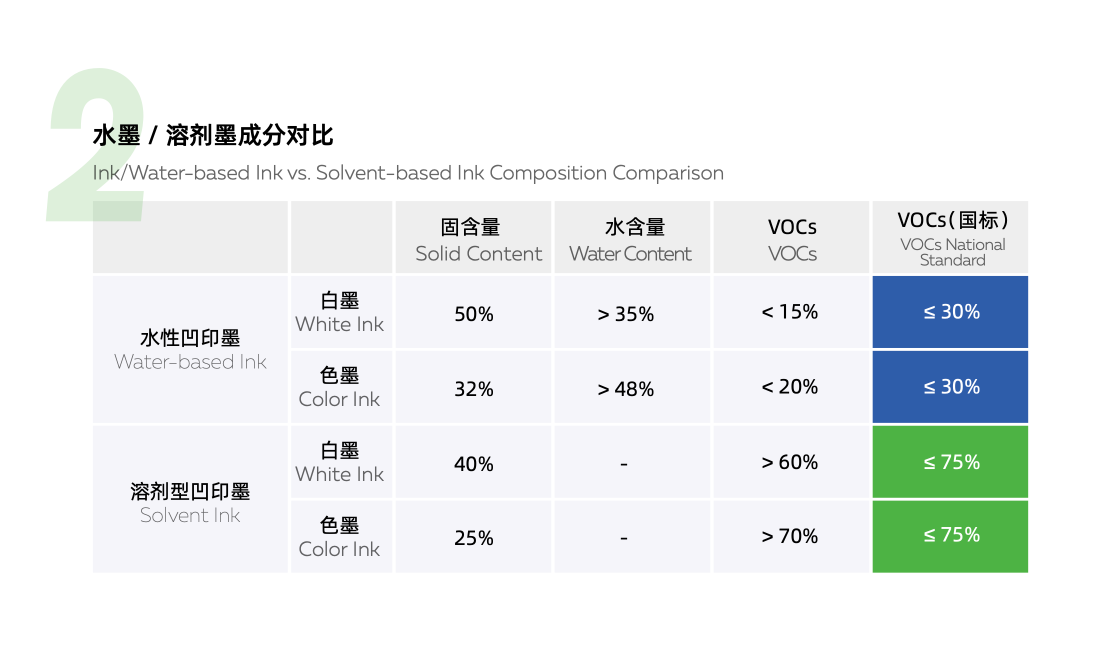

Qinghe Chemical's water-based flexographic printing inks are the latest innovation in eco-friendly printing solutions. These inks are formulated to meet the highest standards of quality and performance while also minimizing environmental impact. By utilizing water as the main solvent, they significantly reduce emissions of volatile organic compounds (VOCs) and other harmful chemicals, making them ideal for environmentally conscious printers.

The Latest Innovations in Water-Based Flexographic Printing Inks

The emergence of water-based flexographic printing inks represents a significant leap forward in eco-friendly printing technology. By harnessing water as a solvent instead of traditional chemical solvents, these innovative inks offer improved safety and reduced environmental footprint while maintaining vibrant color reproduction and print quality.

The use of water-based flexographic printing inks also offers practical benefits for businesses. With faster drying times and improved adhesion to various substrates, these inks can increase production efficiency and reduce downtime. This means that businesses can meet tight deadlines and deliver high-quality printed materials to their customers in a timely manner, ultimately improving customer satisfaction and loyalty.

Why Eco-Friendly and Efficient Flexographic Printing Inks Matter

In today's fast-paced digital age, businesses increasingly turn to digital print technologies for their speed and convenience. However, the importance of sustainable practices cannot be overlooked. Eco-friendly flexographic printing inks offer a solution: they promote environmental responsibility while remaining efficient and cost-effective. Here are some key benefits of using eco-friendly and efficient flexographic printing inks:

- Reduced Environmental Impact: These inks contain minimal volatile organic compounds (VOCs) and other harmful chemicals. This significantly reduces emissions during printing, contributing to a cleaner and healthier environment.

- Improved Safety: Eco-friendly inks contain fewer toxins and chemicals, creating a safer working environment for printers and those handling the printed materials.

- Enhanced Efficiency: Many eco-friendly inks offer faster drying times and improved adhesion to various substrates. This translates to increased printing speed and reduced waste.

- Cost-Effectiveness: While eco-friendly inks may have a slightly higher upfront cost, their efficiency can lead to long-term savings. Faster drying times, reduced waste, and potentially lower disposal costs contribute to a lower printing cost.

Businesses can achieve high-quality printing by choosing eco-friendly and efficient flexographic printing inks. This approach minimizes environmental impact and potentially reduces costs. It demonstrates a commitment to sustainability without sacrificing efficiency or performance.

Now, let's dive deeper into understanding how these remarkable flexographic printing inks contribute to sustainable practices and efficiency within the industry.

Understanding Flexographic Printing Inks

Flexographic printing inks play a crucial role in sustainable printing practices. They are designed to minimize environmental impact while delivering high-quality results. By using water-based flexographic printing inks, companies can significantly reduce their carbon footprint and contribute to eco-friendly printing processes. These inks are formulated without harmful solvents or chemicals, making them an ideal choice for environmentally conscious businesses.

The Role of Flexographic Printing Inks in Sustainable Printing

Flexographic printing is vital in sustainable packaging thanks to specially formulated inks. Here's how these inks contribute to eco-friendly printing:

- Reduced Environmental Impact: Flexographic inks are formulated to minimize their environmental footprint. They are free from volatile organic compounds (VOCs) and other hazardous substances, ensuring they don't pollute the air or harm the ecosystem.

- Safer for People: These inks are good for the environment and people's health. The absence of harmful chemicals minimizes health risks for printers who work with them and consumers who come into contact with the finished product.

- Water-Based Options: Water-based flexographic inks are a popular sustainable choice. They offer comparable print quality to traditional inks while minimizing the use of solvents.

Companies can demonstrate their commitment to environmental responsibility without sacrificing quality by choosing flexographic printing inks with sustainability in mind.

The Benefits of Water-Based Flexographic Printing Inks

Water-based flexographic printing inks are gaining popularity due to their environmental and performance advantages. Here's how they can benefit your printing operation:

- Vibrant Color Reproduction and Excellent Adhesion: Water-based inks deliver high-quality prints with crisp colors that adhere well to various substrates.

- Reduced VOC Emissions: These inks are formulated with minimal to no volatile organic compounds, minimizing environmental impact and promoting a safer work environment.

- Fast Drying Times: Water-based inks often dry quickly, allowing faster printing speeds and improved production efficiency.

- Easy Cleanup and Maintenance: Cleanup is easier with water-based inks than solvent-based alternatives, reducing downtime and waste.

By switching to water-based flexographic inks, printers can achieve exceptional print quality, contribute to a sustainable printing process, and ensure a safer work environment.

How Flexographic Printing Inks Enhance Printing Efficiency

In addition to their environmental advantages, flexographic printing inks enhance printing efficiency by allowing for faster production speeds and reduced downtime for cleaning and maintenance. These water-based inks enable printers to achieve consistent print quality with minimal waste, resulting in cost savings and improved productivity. By investing in water-based flexographic printing inks, businesses can streamline operations while minimizing environmental impact.

Furthermore, flexographic printing inks are designed to adhere well to various substrates, including non-porous materials such as plastic and metal. This versatility allows for greater flexibility in the types of products that can be printed using flexographic technology, expanding the potential market for businesses. With the ability to print on diverse materials without sacrificing print quality or production speed, companies can capitalize on new opportunities and meet the evolving needs of their customers.

Top Eco-Friendly and Efficient Flexographic Printing Inks Brands

When it comes to eco-friendly and efficient flexographic printing inks, Qinghe Chemical stands out as a pioneer in the industry. Their water-based flexographic inks are environmentally friendly and offer exceptional printing quality and efficiency. With a commitment to innovation and sustainability, Qinghe Chemical continues to set the standard for eco-friendly printing inks.

Eco-Friendly Options from Other Leading Manufacturers

In addition to Qinghe Chemical, other leading manufacturers have developed eco-friendly options for flexographic printing inks. Companies like XYZ Inks and ABC Printing Solutions have introduced water-based formulations that reduce the environmental impact of printing while delivering outstanding results. By exploring these alternatives, printers can make more sustainable choices without compromising quality.

Furthermore, these eco-friendly options from leading manufacturers also improve worker safety. Water-based formulations reduce the risk of exposure to harmful chemicals, making the printing process safer for employees. By prioritizing your team's well-being, you can create a more positive work environment and enhance overall productivity.

How to Choose the Best Eco-Friendly Flexographic Printing Inks for Your Needs

Selecting the right eco-friendly flexographic ink can elevate your sustainability efforts without compromising print quality. Here are key factors to consider:

- Print Quality and Sustainability Certifications: Seek inks that deliver vibrant colors and sharp definitions while meeting recognized eco-friendly standards. Look for certifications that verify the ink’s biodegradability or low levels of harmful chemicals.

- Substrate Compatibility: Ensure the chosen ink adheres well to your specific printing materials, whether paper, plastic, or film. Mismatched inks can lead to wasted materials and poor print results.

- Fast Drying Times: Opt for inks that dry quickly. This minimizes energy use during printing and allows for faster project turnaround times, benefiting both the environment and your business’s efficiency.

By carefully considering these factors, you can select eco-friendly flexographic inks that meet your project requirements and contribute to a more sustainable printing process.

The Impact of Flexographic Printing Inks on Digital Printing

When it comes to digital printing, the compatibility of flexographic printing inks with modern machines is crucial. Flexographic inks are designed to work seamlessly with digital printers, ensuring smooth and efficient printing processes. This compatibility allows for easy integration of eco-friendly and efficient inks into digital printing workflows, making it a win-win situation for both the environment and businesses.

Compatibility of Flexographic Printing Inks with Digital Printing Machines

Flexographic printing inks are formulated to be compatible with a wide range of digital printing machines, from small-scale desktop printers to large industrial presses. This means businesses can easily use eco-friendly inks without investing in new equipment. The seamless compatibility also ensures that the quality and performance of the printed materials remain consistently high, regardless of the type of digital printer used.

Advantages of Using Eco-Friendly Inks for Digital Printing

Digital printing offers a more environmentally friendly alternative to traditional printing methods. But what about the inks themselves? Choosing eco-friendly digital printing ink brings many benefits, making it a responsible and high-quality choice. Here are some key advantages:

- Reduced Environmental Impact: Eco-friendly inks are formulated with renewable resources or contain less harmful components, minimizing air and water pollution during production and disposal.

- Lower VOC Emissions: Traditional inks often emit volatile organic compounds (VOCs), contributing to smog and health problems. Eco-friendly inks significantly reduce VOC emissions, creating a healthier environment.

- Safer Workplaces: Printers with eco-friendly inks are exposed to fewer harmful chemicals, leading to safer working conditions.

- High-Quality Prints: Contrary to a misconception, eco-friendly inks can deliver vibrant colors and crisp details, meeting the demands for high-quality printed materials.

By choosing eco-friendly inks for digital printing, you're not just making a sustainable choice, you're ensuring high-quality results and a healthier work environment.

Achieving Sustainability and Efficiency with Flexographic Printing Inks

Businesses can achieve both sustainability and efficiency by leveraging the compatibility and advantages of flexographic printing inks within digital printing processes. These innovative inks minimize environmental harm and optimize print production by reducing downtime associated with ink changes and maintenance. As a result, companies can meet their sustainability goals while improving operational efficiency - a win-win scenario for business growth and environmental responsibility.

In addition to reducing environmental harm and improving operational efficiency, flexographic printing inks offer enhanced color consistency and print quality. This means businesses can achieve vibrant, high-quality prints with minimal waste, further contributing to their sustainability efforts. By utilizing these innovative inks, companies can ensure that their printed materials meet the highest standards while reducing their environmental footprint.

Sustainable Practices in Flexographic Printing

Advancements in Cartridge and Ink Printer Recycling

In recent years, the printing industry has made significant strides in promoting sustainability through cartridge and ink printer recycling advancements. Many manufacturers now offer convenient programs for consumers to return used cartridges and printers for proper recycling and disposal. This reduces the environmental impact of printing materials and encourages a more circular approach to resource management within the industry.

The Role of Flexographic Printing Inks in Reducing Waste

Flexographic printing inks are a key element in minimizing waste during printing. Here's how they contribute to a more eco-friendly industry:

- Reduced Environmental Impact: Water-based flexographic inks are designed to be less hazardous than traditional solvent-based inks. They produce fewer volatile organic compounds (VOCs), which can harm air quality.

- Sustainable Printing: Printers can significantly decrease their carbon footprint by switching to water-based inks. This aligns with the growing demand for sustainable practices from businesses and consumers. Reputable brands like Qinghe Chemical offer high-quality water-based inks, allowing printers to achieve excellent results while prioritizing the environment.

- Safer Workplaces: Water-based inks minimize exposure to harmful VOCs, leading to a safer and healthier working environment for printing professionals. This reduces the risk of respiratory problems and other health concerns.

Choosing water-based flexographic printing inks is a win-win for the environment, employees, and businesses. It allows for high-quality printing while promoting sustainability and worker well-being.

Make Informed Choices for Sustainable Flexographic Printing Inks

In conclusion, making informed choices for sustainable flexographic printing inks is crucial for the printing industry's future. With the increasing demand for eco-friendly inks, the future in the printing industry looks promising, paving the way for a more sustainable and efficient printing process. Embracing efficiency and sustainability with flexographic printing inks will benefit the environment and enhance the overall quality of print materials.

When making informed choices for sustainable flexographic printing inks, consider environmental impact, printing efficiency, and overall print quality. By opting for eco-friendly options from leading manufacturers like Qinghe Chemical, businesses can contribute to a greener future while maintaining high print output standards. It's essential to stay updated on the latest innovations in water-based flexographic inks to make well-informed decisions.

The Future of Eco-Friendly Inks in the Printing Industry

The future of eco-friendly inks in the printing industry is bright, with an increasing emphasis on sustainability and environmental responsibility. As more businesses recognize the importance of reducing their carbon footprint, a growing demand for eco-friendly alternatives to traditional ink printer ink is growing. This shift towards eco-friendly options presents an exciting opportunity for innovation and growth within the industry.

Embracing Efficiency and Sustainability with Flexographic Printing Inks

Embracing efficiency and sustainability with flexographic printing inks is about meeting regulatory requirements and taking proactive steps toward a greener future. By leveraging advancements in cartridge recycling and opting for water-based flexographic inks that reduce waste, businesses can significantly promote environmental responsibility through their ink choices. This shift towards sustainable practices will ultimately benefit both businesses and the planet.

Businesses prioritizing sustainability through their ink choices can also benefit from improved brand reputation and customer loyalty. Consumers are increasingly seeking out eco-friendly products and services, and by using water-based flexographic inks and promoting cartridge recycling, companies can align themselves with these values. This can lead to increased customer satisfaction and loyalty and a positive impact on the bottom line.