Introduction

Ink jet film is a versatile material that offers numerous benefits for printing projects. Whether it's ink jet adhesive film, transparency film for ink jet printer, or ink jet shrink film, these specialized films provide high-quality results for various applications. Choosing the right ink jet film is crucial to achieving professional-looking prints, and with the right tips and techniques, successful ink jet film printing is easily achievable.

Benefits of Using Ink Jet Film

Adopting ink jet film in various applications brings forth a spectrum of advantages, enhancing visual appeal, functionality, and versatility in printing. This list outlines the diverse benefits of utilizing ink jet film, spanning vibrant color reproduction, image clarity, quick drying times, strong label adhesion, presentation transparency, and unique shrinking properties for custom packaging.

- Vibrant Color Reproduction: Ink jet film excels in vibrant color reproduction, ensuring that printed materials captivate attention and convey information with striking visual appeal.

- Sharp Image Clarity: The technology of ink jet film guarantees sharp image clarity, allowing for the precise reproduction of intricate details and enhancing the overall quality of printed graphics.

- Quick Drying Times: Ink jet film offers the advantage of quick drying times, facilitating efficient printing processes and minimizing the risk of smudging or print imperfections.

- Strong Bond for Labels and Stickers: Ink jet adhesive film provides a robust bond, making it ideal for crafting durable labels and stickers that adhere securely to various surfaces.

- Transparency for Presentations: Transparency film designed for ink jet printers enables the creation of clear and crisp overhead transparencies, enhancing the visual impact of presentations.

- Unique Shrinking Properties: Ink jet shrink film possesses unique shrinking properties, making it an ideal choice for crafting custom packaging and promotional materials that conform precisely to the contours of the packaged items.

Using ink jet film extends beyond conventional printing, offering various benefits. From vivid color reproduction to strong adhesion and unique shrinking properties, ink jet film is a valuable tool for creating visually appealing and functionally robust printed materials across various applications.

Choosing the Right Ink Jet Film

The success of a printing project hinges on choosing the right ink jet film tailored to its unique requirements. Grafix ink jet film stands out as a versatile option, offering a range of choices such as clear or matte finishes and various thicknesses. This list highlights the importance of understanding these options, particularly in distinguishing between ink jet adhesive film, transparency film, and shrink film, to ensure the selection aligns with specific project needs.

- Clear or Matte Finishes: Grafix ink jet film provides the flexibility of clear or matte finishes, allowing users to tailor the visual presentation of their printed materials based on the desired aesthetic and practical requirements.

- Various Thicknesses: The availability of different thickness options ensures that Grafix ink jet film can meet diverse printing needs, providing choices that cater to both the delicacy and durability required for specific applications.

- Ink Jet Adhesive Film: For projects requiring strong adhesion, ink jet adhesive film from Grafix is an ideal choice. It ensures a secure bond for labels and stickers, enhancing durability and longevity.

- Transparency Film: When clear, crisp overhead transparencies are essential for presentations, Grafix transparency film designed for ink jet printing is a reliable option, ensuring optimal clarity and visibility.

- Shrink Film: Grafix ink jet shrink film stands out for its unique shrinking properties, making it suitable for crafting custom packaging and promotional materials that conform precisely to the contours of the packaged items.

Selecting the right ink jet film is pivotal in achieving optimal printing results. Grafix ink jet film's diverse options, encompassing finishes and thicknesses, along with specific offerings like adhesive film, transparency film, and shrink film, provide users with the tools needed to tailor their choices to the unique demands of each printing project.

Tips for Successful Ink Jet Film Printing

Achieving professional-quality prints on ink jet film requires careful consideration of various factors. This list provides essential tips for successful ink jet film printing, covering proper material loading, printer setting adjustments, and techniques that collectively contribute to avoiding issues such as jams, misalignment, inaccurate color representation, smudging, or bleeding during the printing process.

- Proper Material Loading: Ensure proper loading of the ink jet film into the printer to prevent jams or misalignment. Follow the printer manufacturer's guidelines for loading film, providing a smooth and consistent printing surface.

- Adjust Printer Settings: Customize printer settings specifically for ink jet films. Adjust parameters such as print quality, paper type, and color profiles to achieve accurate color representation and prevent potential issues like smudging or bleeding.

- Color Calibration: Calibrate the printer for color accuracy, especially when working with ink jet films that require precise color representation. This ensures that the printed output aligns with the intended design.

- Print a Test Page: Before initiating a full printing job, print a test page on a small section of the ink jet film. This allows for adjustments and ensures that the chosen settings and materials are conducive to the desired print quality.

- Use High-Quality Inks: Opt for high-quality, compatible inks for ink jet film printing. The use of reliable ink contributes significantly to achieving sharp, vibrant, and long-lasting prints.

- Allow Sufficient Drying Time: Ink jet films may require additional drying time. Ensure adequate drying time between prints to prevent smudging or sticking, particularly when handling the printed materials immediately after printing.

- Handle with Care: Handle the printed ink jet film with care to avoid scratches or damage. Consider allowing prints to fully dry before stacking or further processing.

- Clean Printer Heads Regularly: Regularly clean the printer heads to maintain optimal printing performance. This prevents clogs or inconsistencies that could affect the quality of prints on ink jet film.

Successful ink jet film printing involves a combination of proper handling, adjustments to printer settings, and attention to details like color calibration and drying time. By following these tips and techniques, achieving professional-quality prints on various types of ink jet films becomes a streamlined and efficient process.

Understanding Ink Jet Film

When it comes to ink jet film, there are several types to choose from, including adhesive film, transparency film, and shrink film. Each type serves a different purpose and offers unique benefits for various printing needs. Whether you're looking for a durable adhesive film for labels or a high-quality transparency film for presentations, an ink jet film option is perfect for your project.

Types of Ink Jet Film

Ink jet adhesive film is ideal for creating custom stickers, labels, and decals with vibrant colors and sharp details. Transparency film for ink jet printers allows you to produce clear, crisp overhead transparencies for presentations and educational purposes. Meanwhile, ink jet shrink film is designed to create heat-shrinkable packaging and labels that conform to the shape of your product.

Differences in Ink Jet Adhesive Film, Transparency Film, and Shrink Film

1. Ink Jet Adhesive Film:

- Intended Use: Designed for labels and stickers requiring strong adhesion.

- Characteristics: Sticky on one side, facilitating easy application onto various surfaces.

- Application: Ideal for creating durable labels that adhere securely to different materials.

2. Transparency Film:

- Intended Use: Primarily for presentations, where clear and crisp overhead transparencies are essential.

- Characteristics: Clear and transparent, allowing light to pass through for projection.

- Application: Designed to be projected onto a screen, enhancing visibility during presentations.

3. Shrink Film:

- Intended Use: Perfect for packaging and labeling items of various shapes and sizes.

- Characteristics: Can shrink tightly around objects when heat is applied.

- Application: Ideal for creating custom packaging and promotional materials, conforming precisely to the contours of the packaged items.

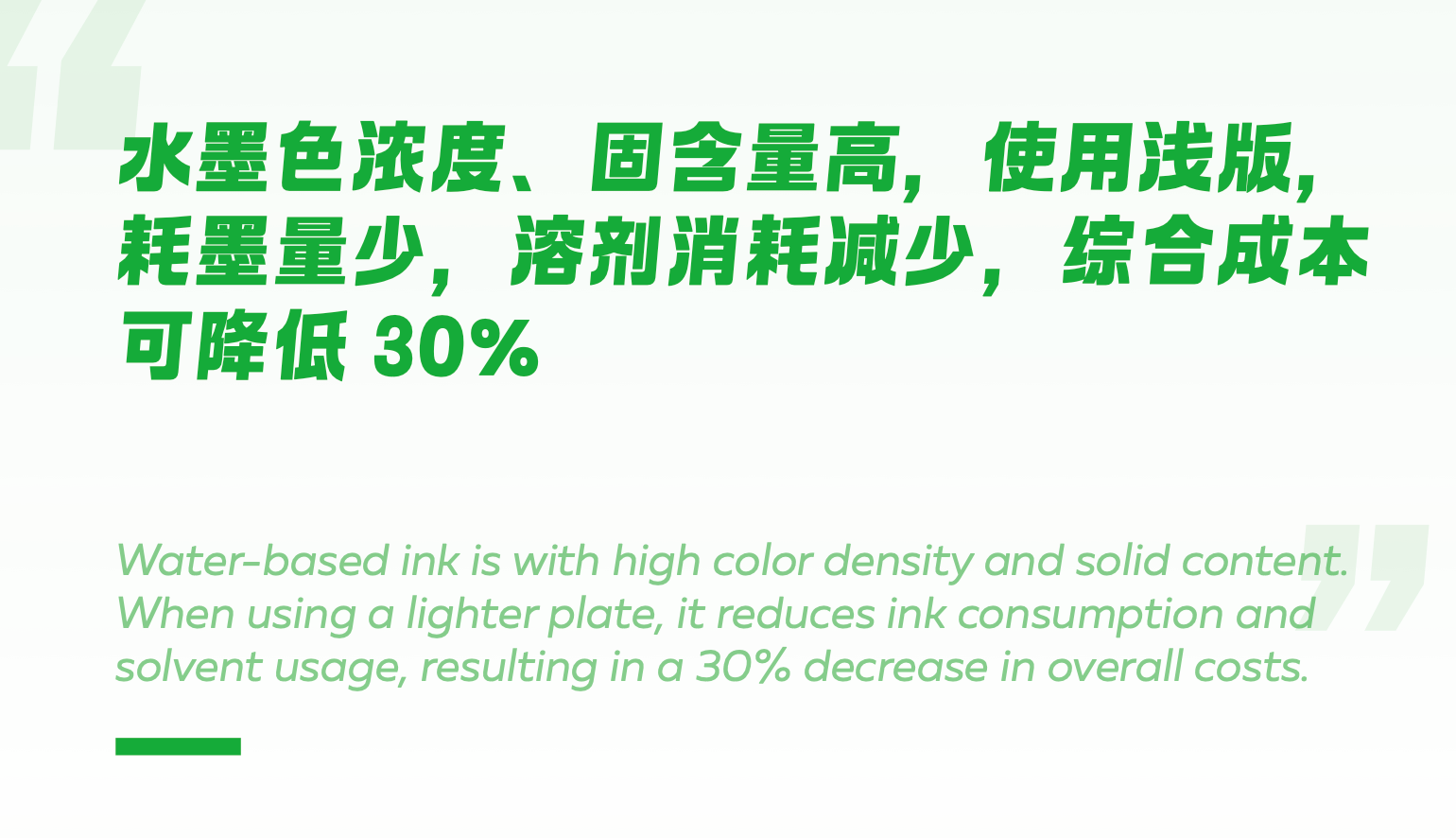

The Role of Qinghe Chemical in Ink Jet Film Development

Qinghe Chemical has been at the forefront of ink jet film development, continuously innovating to improve the quality and versatility of their products. With their commitment to research and development, Qinghe Chemical has played a crucial role in expanding the capabilities of ink jet adhesive film, transparency film, and shrink film to meet the evolving needs of consumers.

Qinghe Chemical has also been instrumental in addressing environmental concerns related to ink jet film production. Investing in eco-friendly manufacturing processes and materials, the company has demonstrated a commitment to sustainability and reducing its carbon footprint. This proactive approach benefits the environment and positions Qinghe Chemical as a leader in responsible business practices within the industry.

Preparing for Printing

When preparing to print on ink jet film, it's crucial to properly load the film into your printer to avoid jams and smudges. Handle the film carefully to prevent any creases or tears that could affect print quality. Additionally, ensure that the printer's paper tray is adjusted to accommodate the thickness of the ink jet film.

Properly Loading Ink Jet Film

To load ink jet film, gently fan the sheets to separate them and then place them into the printer's paper tray with the printable side facing down. Adjust the paper guide so that it lightly touches the edge of the film stack, preventing it from shifting during printing. It's important not to overload the tray with too many sheets, which can cause feeding issues.

Adjusting Printer Settings for Ink Jet Film

Adjust your printer settings before printing on ink jet film to ensure optimal results. Select transparency or film as your paper type and set your print quality high for vibrant colors and sharp details. You may also need to adjust your printer's speed and temperature settings depending on the type of ink jet film you're using.

Ensuring Compatibility with Grafix Ink Jet Film

When using Grafix ink jet film, it's essential to check for compatibility with your specific printer model. Some printers may require special settings or adjustments when using third-party ink jet films like those from Grafix. Always refer to the manufacturer's instructions or website for guidance on achieving optimal results with their products.

Remember that proper preparation is key when working with ink jet films to achieve professional-quality prints without wasting materials or time. By following these steps and ensuring compatibility with trusted brands like Grafix, you can confidently bring your creative visions to life on ink jet adhesive films, transparency films for ink jet printers, and shrink films!

Printing Techniques

When achieving high-quality prints on transparency film for ink jet printers, it's essential to ensure that the film is loaded properly and that the printer settings are adjusted accordingly. Transparency film for ink jet printers is designed to produce clear, vibrant images, so select the appropriate print quality and paper type settings on your printer. Additionally, consider using a higher-resolution image file for best results.

Achieving High-Quality Prints on Transparency Film

To achieve high-quality prints on transparency film, clean the printer heads and ensure the ink cartridges are in good condition. It's also important to carefully handle the transparency film to avoid smudges or fingerprints affecting print quality. When printing on transparency film for ink jet printers, ensure the room is well-lit to assess print quality as it comes out accurately.

Tips for Printing on Ink Jet Shrink Film

Printing on ink jet shrink film requires precision to achieve the best results. Follow these essential tips to ensure a seamless printing experience.

- Adjust printer settings: Ensure the printer accommodates the film thickness.

- Lower heat setting: If possible, manually adjust the printer to a lower heat setting.

- Test print on paper: Conduct a test print on regular paper for alignment and image clarity.

- Handle with care: During the shrinking process, handle the printed shrink film carefully for optimal results.

By incorporating these tips into your printing process, you'll enhance the quality and clarity of your images on ink jet shrink film. Print with confidence and achieve professional results every time.

Troubleshooting Common Printing Issues

Common issues when printing on ink jet films include streaks or lines in prints, poor color saturation, and difficulty feeding through printers due to static cling. To troubleshoot these issues, try cleaning your printer's rollers and ensuring you use compatible ink jet adhesive film or transparency film for your specific printer model. If problems persist, contact Grafix Ink Jet Film customer support for personalized assistance.

After addressing the common issues with printing on ink jet films, it's important to focus on proper handling and drying techniques to ensure high-quality prints. When handling ink jet films, avoiding touching the printable surface is essential to prevent smudges or fingerprints affecting print quality. Additionally, sufficient drying time after printing is crucial to prevent smearing or smudging the ink. By carefully handling and allowing proper drying time, you can maximize the quality of your prints on ink jet films.

Handling and Drying

When handling wet ink jet film, it's important to do so carefully to avoid smudging the print. Gently hold the edges of the film to prevent any contact with the ink. Place the film on a flat surface to air dry, ensuring it is not exposed to direct sunlight or high temperatures.

Handling Wet Ink Jet Film

After printing, handle wet ink jet film with care to avoid smudging or damaging the print. Hold the edges of the film lightly and avoid touching the printed surface directly. Lay the film flat on a clean, dry surface and allow it to air dry completely before handling further.

Drying Time for Different Types of Ink Jet Film

The drying time for different types of ink jet film can vary based on factors such as humidity and temperature. Transparency film for ink jet printers typically dries within 5-10 minutes, while ink jet shrink film may take longer due to its thicker material. It's important to allow adequate drying time before handling the prints.

Qinghe's Contributions to Fast-Drying Ink Jet Film

Qinghe Chemical has significantly contributed to fast-drying ink jet films through innovative chemical formulations that promote rapid drying without compromising print quality. Their commitment to enhancing user experience sets them apart in the industry, providing customers with efficient and reliable products that deliver professional results in record time.

Post-Printing Care

Now that you've successfully printed on your ink jet film, it's important to take care of it to ensure longevity and quality. Protecting the printed ink jet film from scratches and smudges is crucial for preserving the image. Storing the film in a cool, dry place away from direct sunlight and extreme temperatures will help maintain its integrity over time.

Protecting Printed Ink Jet Film

Consider using a clear plastic sleeve or a protective folder to protect your printed ink jet film to prevent any damage during handling and storage. Avoid touching the printed side directly to minimize fingerprints or smudges. If you need to handle the film directly, ensure your hands are clean and dry to avoid unwanted marks.

Storing Ink Jet Film for Longevity

Storing your ink jet film properly is key to ensuring its longevity. Keep it flat to prevent warping or bending, and avoid stacking heavy objects on top of it. Consider using archival-quality storage materials for long-term preservation, such as acid-free sleeves or boxes for storing ink jet film.

Qinghe's Sustainable Initiatives in Ink Jet Film Production

Qinghe Chemical is committed to sustainable initiatives in ink jet film production, focusing on reducing environmental impact through eco-friendly manufacturing processes and materials. Qinghe sets an industry standard for responsible production practices that benefit consumers and the environment by incorporating recyclable components and minimizing waste generation.

Achieve Professional Results with Ink Jet Film

When achieving professional results with ink jet film, choosing the right type for your specific printing needs is essential. Whether you're using ink jet adhesive film, transparency film for ink jet printer, or ink jet shrink film, understanding the differences and proper printing techniques is key to success.

To achieve professional results with ink jet film, following the manufacturer's guidelines for loading, adjusting printer settings, and handling the printed film is crucial. Whether you're using grafix ink jet film or another brand, preparing and printing properly will ensure high-quality results that meet your expectations.

Sustainable Practices in Ink Jet Film Production

Ink jet film production can have a significant environmental impact if not handled responsibly. Look for companies like Qinghe Chemical that prioritize sustainable practices in their production processes. By choosing eco-friendly options and supporting companies with green initiatives, you can contribute to a more sustainable future.

Qinghe's Ongoing Innovation in Eco-Friendly Ink Jet Film

Qinghe Chemical has been at the forefront of innovation in eco-friendly ink jet film production. Their commitment to developing fast-drying ink jet film and exploring new materials for sustainability sets them apart as an industry leader. By supporting their ongoing efforts, you're getting top-quality products and contributing to a greener planet.

Remember, achieving professional results with ink jet film requires attention to detail and understanding the specific type of film you're working with. By following best practices and supporting sustainable initiatives in production, you can enjoy high-quality prints while minimizing your environmental impact. Choose wisely and print responsibly!