Introduction

In the ever-evolving world of textile printing, water-based inks have emerged as game-changers, and Qinghe Chemical is leading the charge. With their innovative approach to water-based textile inks, they are revolutionizing the industry and setting new standards for eco-friendly printing solutions. As the demand for sustainable options continues to rise, water-based inks are positioning themselves as the future of textile printing.

Qinghe Chemical: Leading the Way in Water-Based Inks

Qinghe Chemical has established itself as a trailblazer in developing and manufacturing water-based textile inks for screen printing. Their commitment to quality and sustainability has made them a top choice for printing ink suppliers worldwide. With a focus on vibrant color reproduction and eco-friendly practices, Qinghe Chemical is at the forefront of driving positive change in the industry.

The Rise of Water-Based Textile Inks

The rise of water-based inks for screen printing can be attributed to their numerous benefits, including enhanced breathability in textiles and their eco-friendly nature. As more consumers gravitate towards sustainable fashion choices, the demand for water-based textile inks continues to grow exponentially. This shift indicates a larger trend towards environmentally conscious practices within the textile industry.

Why Water-Based Inks are the Future

Water-based inks are gaining traction in textile printing for a reason. They offer several advantages over traditional solvent-based inks:

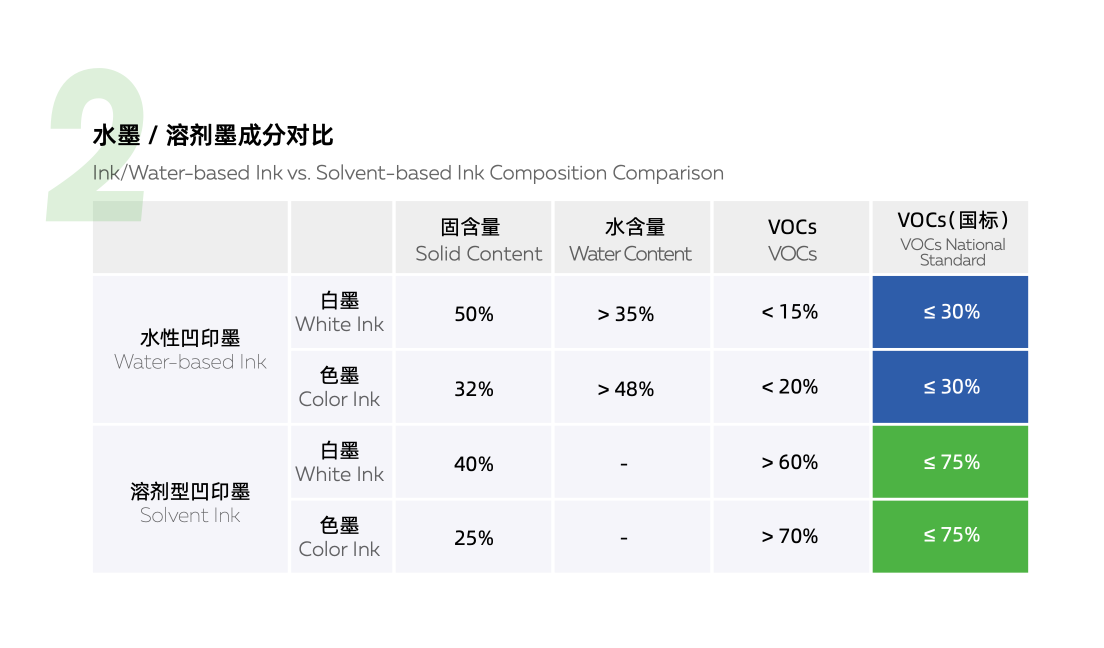

- Environmentally Friendly: Water-based inks are formulated with minimal volatile organic compounds (VOCs), significantly reducing air pollution and creating a safer work environment.

- Vibrant Colors: Despite being eco-friendly, water-based inks can still deliver crisp, vivid colors that rival solvent-based inks.

- Safer for Workers and Consumers: Since they contain fewer harmful chemicals, water-based inks pose less of a health risk to those working with them and those wearing the finished product.

- Softer Hand Feel: Water-based inks dry thin and flexible, resulting in a more comfortable and natural feel on fabrics than the plastic-like residue solvent-based inks can leave.

With their environmental benefits and user-friendly qualities, water-based inks are poised to become the new standard in textile printing.

Benefits of Using Water-Based Textile Inks

Water-based textile inks are revolutionizing the printing industry with their vibrant color reproduction, making designs pop on fabrics like never before. Unlike traditional solvent-based inks, water-based inks penetrate deeply into the fabric fibers, resulting in long-lasting and vivid prints that stand the test of time.

Vibrant Color Reproduction

With water-based inks for screen printing, you can achieve unparalleled color vibrancy and clarity on textiles. The inks seamlessly blend with the fabric, creating a soft hand feel and allowing for intricate designs to be printed with precision. This makes water-based textile inks the go-to choice for designers who demand high-quality results. These eco-friendly inks are also free from harsh chemicals, making them safe for the environment and those who come into contact with the printed textiles. This environmentally conscious approach to printing is a significant selling point for businesses looking to reduce their carbon footprint.

Eco-Friendly Printing Option

Water-based inks are revolutionizing sustainable fashion by offering a safe and comfortable alternative to traditional printing methods. Here's why they're a win-win for the environment and consumers:

- Eco-Friendly: Water-based inks ditch harmful chemicals and VOCs, minimizing pollution and ensuring a safer environment.

- Safer Production & Wear: Free from toxins, water-based inks pose less risk to factory workers and enhance the safety of the clothing for the wearer.

- Enhanced Comfort: Unlike plastisol inks, water-based inks create a softer feel on fabrics, resulting in more breathable and comfortable clothing, perfect for activewear or everyday wear.

As the demand for sustainable fashion rises, water-based inks offer an intelligent solution for brands seeking to align with eco-conscious values while delivering high-quality products. By switching, brands can contribute to a healthier planet and provide consumers with comfortable, eco-friendly clothing choices.

Enhanced Breathability in Textiles

One of the most underrated benefits of using water-based textile inks is their ability to enhance fabric breathability. Unlike plastisol ink, which creates a thick layer on top of the fabric, water-based ink seeps into the fibers, preserving the material's natural texture and breathability. This is particularly important for activewear and sportswear, where comfort is key.

Now that we've explored the benefits of using water-based textile inks let's explore some top picks for screen printing with these innovative, eco-friendly options.

Top Water-Based Inks for Screen Printing

When it comes to top-quality water-based textile inks for screen printing, Qinghe Chemical is leading the way with its innovative and eco-friendly products. Its water-based inks are designed to deliver vibrant and long-lasting color reproduction on textiles, making it a popular choice among printing ink suppliers. With a focus on sustainability and performance, Qinghe's water-based inks are perfect for any textile printing project.

Qinghe's Water-Based Textile Inks

Qinghe's water-based textile inks are formulated to meet the demands of modern textile printing, offering excellent color saturation and durability without compromising on environmental impact. These inks are ideal for screen printing applications, providing exceptional wash fastness and color retention on various fabrics. As a leading manufacturer of water-based inks, Qinghe Chemical continues to innovate and set new standards for sustainable printing solutions.

Water-Based Inks for Sustainable Fashion

In the world of fashion, sustainable practices are becoming increasingly important, and water-based inks are playing a key role in this movement. Many designers and brands are turning to water-based textile inks as a more eco-friendly alternative to traditional solvent-based options. By using these inks, fashion industry professionals can reduce their environmental footprint while achieving high-quality results that meet consumer demand for sustainable products.

Furthermore, water-based inks offer a safer working environment for textile printers, as they do not emit harmful fumes or toxins during printing. This benefits workers' health and contributes to a more sustainable and ethical supply chain within the fashion industry. Water-based inks are known for producing vibrant and long-lasting colors on fabric, ensuring that sustainable fashion pieces maintain their visual appeal over time.

Advantages of Using Water-Based Inks in Textile Printing

Water-based inks are gaining traction in textile printing for several reasons. Here are some key benefits:

- Enhanced printability and comfort: Water-based inks offer vibrant color reproduction and excellent wash fastness. They also provide superior breathability in fabrics, making them ideal for activewear and performance garments.

- Safer for people and the planet: Water-based inks are free from harmful VOCs (volatile organic compounds), reducing health risks for printers and improving indoor air quality. Additionally, they require less energy and water to produce compared to traditional solvent-based inks, minimizing environmental impact.

- Sustainable choice for the future: By choosing water-based inks, textile manufacturers can reduce their carbon footprint and cater to the growing demand for eco-friendly products, appealing to environmentally conscious consumers.

Water-based inks offer a compelling combination of printability, safety, and sustainability, making them a valuable option for the future of textile printing.

Water-Based Inks vs. Traditional Solvent-Based Inks

Eliminating Harmful VOCs

Water-based textile inks are a game-changer in the industry, as they eliminate harmful volatile organic compounds (VOCs) commonly found in traditional solvent-based inks. These VOCs are known to have adverse effects on human health and the environment, making water-based inks a much safer and more sustainable option for textile printing.

Water-based textile inks not only eliminate harmful VOCs but also offer improved air quality in the printing environment. Traditional solvent-based inks release toxic fumes into the air during the printing process, contributing to indoor air pollution. By switching to water-based inks, textile printers can create a healthier work environment for their employees and reduce their carbon footprint at the same time.

Health and Safety Benefits

The shift towards water-based inks for screen printing also brings significant health and safety benefits to printing industry workers. With reduced VOCs, workers are no longer exposed to hazardous fumes during printing, leading to improved indoor air quality and overall well-being.

Environmental Impact of Water-Based Inks

Another key factor driving their increasing popularity is the environmental impact of water-based inks. Unlike solvent-based inks, which release harmful chemicals into the atmosphere, water-based inks offer a much greener alternative with minimal impact on air and water quality, ultimately contributing to a healthier planet for future generations.

Remember that switching to water-based inks is not just about embracing a trend; it's about making a responsible choice for the future of textile printing and our planet.

Innovations in Water-Based Ink Technology

When it comes to sustainable practices, Qinghe Chemical leads the way in water-based textile inks. Their commitment to eco-friendly printing options and vibrant color reproduction has set a new standard in the industry. By using water-based inks for screen printing, they have shown that it's possible to achieve high-quality results while minimizing environmental impact.

Qinghe Chemical's Sustainable Practices

Qinghe Chemical has revolutionized the future of water-based inks with its innovative approach to sustainable practices. Its water-based inks for screen printing are not only vibrant and long-lasting but also eco-friendly and safe for use on textiles. By prioritizing sustainability, it has become one of the top printing ink suppliers for those looking to make a positive impact on the environment.

The Future of Water-Based Inks

As the demand for eco-friendly solutions continues to grow, the future of water-based inks looks bright. With advancements in technology and a shift towards sustainable fashion, more and more companies are embracing water-based textile inks as the go-to option for their printing needs. This shift is not just a trend; it's a necessary step towards reducing our environmental footprint.

The demand for water-based inks is driven by increasing consumer awareness and demand for sustainable products. As more people become conscious of the environmental impact of their purchasing decisions, companies are under pressure to adopt eco-friendly practices. Water-based inks offer a solution that meets this demand, as they are non-toxic, produce minimal waste, and have a lower environmental impact than traditional solvent-based inks.

Advancements in Water Based Ink Manufacture

Advances in water-based ink manufacture have paved the way for more environmentally friendly options that don't compromise on quality. Printing ink suppliers are now focusing on developing innovative formulations that offer vibrant color reproduction without harmful VOCs or chemicals. These advancements are reshaping the industry and proving that water-based inks are here to stay.

The shift towards water-based inks is also driven by consumer demand for more sustainable products. As people become more aware of the environmental impact of traditional printing inks, they seek safer alternatives for both the planet and the people who use them. This increased awareness pressures printing ink suppliers to continue innovating and improving their water-based ink formulations to meet these changing consumer preferences.

The Future of Textile Printing

Water-based textile inks are revolutionizing the printing industry, offering vibrant color reproduction, eco-friendly options, and enhanced breathability in textiles. Making the switch to water-based inks is not just a trend; it's the future of textile printing. By embracing sustainable solutions and innovative technology from top printing ink suppliers like Qinghe Chemical, we can ensure a brighter, cleaner future for the industry.

Making the Switch to Water-Based Inks

The benefits of water-based inks for screen printing are undeniable. With vibrant color reproduction and eco-friendly options, it's time for businesses to switch to water-based inks for a more sustainable and efficient printing process. Printing ink manufacturing has evolved to meet the demand for water-based ink, making it easier to transition away from traditional solvent-based inks.

As more businesses and consumers become environmentally conscious, the demand for sustainable printing continues to grow. Water-based inks offer a solution that meets this demand, providing vibrant colors and eco-friendly options without compromising on quality. With advancements in printing ink manufacture, businesses can now easily make the switch to water-based inks, reducing their environmental impact and meeting the needs of a more eco-conscious market.

As technology advances and consumer demand for sustainable fashion grows, the future of textile printing lies in water-based textile inks. With their ability to produce high-quality prints while reducing environmental impact, water-based inks are paving the way for a new textile design and production era. In addition to being eco-friendly, water-based inks offer excellent color vibrancy and durability, ensuring that printed textiles maintain their quality over time. This makes them a perfect choice for designers looking to create long-lasting, visually stunning garments.

Embracing Sustainable Solutions

In an industry historically associated with harmful VOCs and environmental damage, embracing sustainable solutions like water-based inks is crucial. Businesses can reduce their carbon footprint and contribute to a cleaner planet by choosing eco-friendly options from top printing ink suppliers.

By switching to water-based inks, businesses can also improve the safety and health of their employees. Traditional solvent-based inks release harmful VOCs into the air, leading to respiratory issues and other health problems for workers. By using water-based inks, companies can create a healthier and safer work environment for their employees, reducing absenteeism and increasing productivity.