Introduction

Understanding Cold-Seal Inks

Cold-seal inks are specialized adhesives that bond without the need for heat, making them perfect for various applications in flexible packaging. These inks are particularly popular in shrink wrapping ink processes, where maintaining the integrity of the product while ensuring effective sealing is paramount. By utilizing cold-seal technology, manufacturers can achieve efficient production cycles while reducing energy consumption.

Key Factors in Supplier Selection

Selecting a reliable supplier for your cold-seal inks involves evaluating several key factors that can significantly impact your operations. First and foremost, consider their experience in the industry—how long have they been providing cold seal heat-sensitive packaging solutions? Additionally, assessing their reputation and customer testimonials can provide valuable insights into their reliability and product performance.

The Importance of Quality

Quality should never be compromised when it comes to selecting a cold-seal ink supplier; after all, inferior products can lead to costly mistakes down the line. High-quality inks not only ensure effective adhesion but also contribute to the overall aesthetic appeal of flexible packaging designs. Therefore, understanding what constitutes quality in this context will help you make informed decisions that align with your business goals.

What Are Cold-Seal Inks?

Cold-seal inks are a unique type of adhesive ink that bond materials without the need for heat. They are primarily used in flexible packaging applications, where the ability to seal at lower temperatures is beneficial. This makes them an ideal choice for sensitive products or materials that could be damaged by traditional heat-based sealing methods.

Definition and Uses

Cold-seal inks are specially formulated to adhere substrates upon contact, creating a strong bond without the application of heat. These inks are commonly used in various packaging solutions, including food wrappers, pouches, and labels. Their versatility allows them to be employed in both consumer goods and industrial applications, making them a popular choice for businesses looking to enhance their packaging processes.

Benefits Over Traditional Inks

One of the standout benefits of cold-seal inks over traditional inks is their ability to create secure seals without heating elements. This not only saves energy but also reduces production costs associated with heating equipment and cooling time after sealing. Additionally, cold seal heat-sensitive packaging maintains product integrity better than heated methods, ensuring freshness and quality during storage and transport.

Application in the Packaging Industry

In the realm of flexible packaging, cold-seal inks shine brightly due to their efficiency and effectiveness in various applications. They are particularly useful in shrink wrapping ink processes where maintaining product temperature is crucial—think of those delightful snacks that stay fresh longer! Furthermore, when considering how to choose a cold-seal ink supplier, it’s essential to look at their experience with these specific applications as this can significantly impact your product's success on the shelf.

Evaluating Supplier Experience

Years in Business

A seasoned supplier with many years in the industry is likely to have refined their processes and product offerings over time. This longevity not only speaks to their stability but also suggests that they have weathered market fluctuations and adapted to changing demands, including innovations like flexible packaging solutions. When considering how to choose a cold-seal ink supplier, look for those with at least five years of experience, as this can indicate a solid foundation of knowledge and reliability.

Industry Reputation

The reputation of a cold-seal ink supplier within the industry is critical for making an informed choice. Suppliers known for high-quality products are often recommended by peers or industry associations, making them stand out when you're exploring what is flexible packaging options available today. Additionally, a good reputation means that the supplier has likely built strong relationships with clients through consistent delivery of cold seal heat-sensitive packaging solutions that meet or exceed expectations.

Customer Testimonials

Customer testimonials are invaluable when evaluating potential suppliers for your cold seal inks needs. Positive feedback from previous clients can provide insight into not only product quality but also customer service and support—both essential elements when choosing how to choose a cold-seal ink supplier effectively. Moreover, reviews may highlight specific applications such as shrink wrapping ink performance or other specialized uses, helping you make an informed decision based on real-world experiences.

Assessing Product Quality

Ingredient Sourcing

Ingredient sourcing is the backbone of any high-quality cold seal ink. To choose a reliable cold-seal ink supplier, it's essential to understand where they source their raw materials from. Suppliers that prioritize high-quality ingredients are more likely to produce inks that perform well in flexible packaging applications, ensuring that your shrink wrapping ink adheres properly and provides optimal sealing properties.

Furthermore, transparency in ingredient sourcing reflects a supplier's commitment to quality and sustainability. A reputable supplier will provide detailed information about their ingredients and their origins, giving you peace of mind regarding the safety and efficacy of their products. This diligence not only enhances product performance but also helps in maintaining your brand's reputation for using top-notch materials.

Performance Standards

Performance standards are critical when evaluating potential suppliers for cold seal inks. You’ll want to know how well their products perform under various conditions typical in flexible packaging environments. A good supplier should offer data on adhesion strength, drying times, and compatibility with different substrates commonly used in shrink wrapping ink applications.

In addition to basic performance metrics, consider asking about any certifications or testing procedures the supplier employs to validate their claims. High-performance inks should withstand factors like temperature fluctuations and humidity without compromising integrity or functionality. By focusing on these aspects, you can confidently select a supplier whose inks will meet your operational needs effectively.

Compliance with Safety Regulations

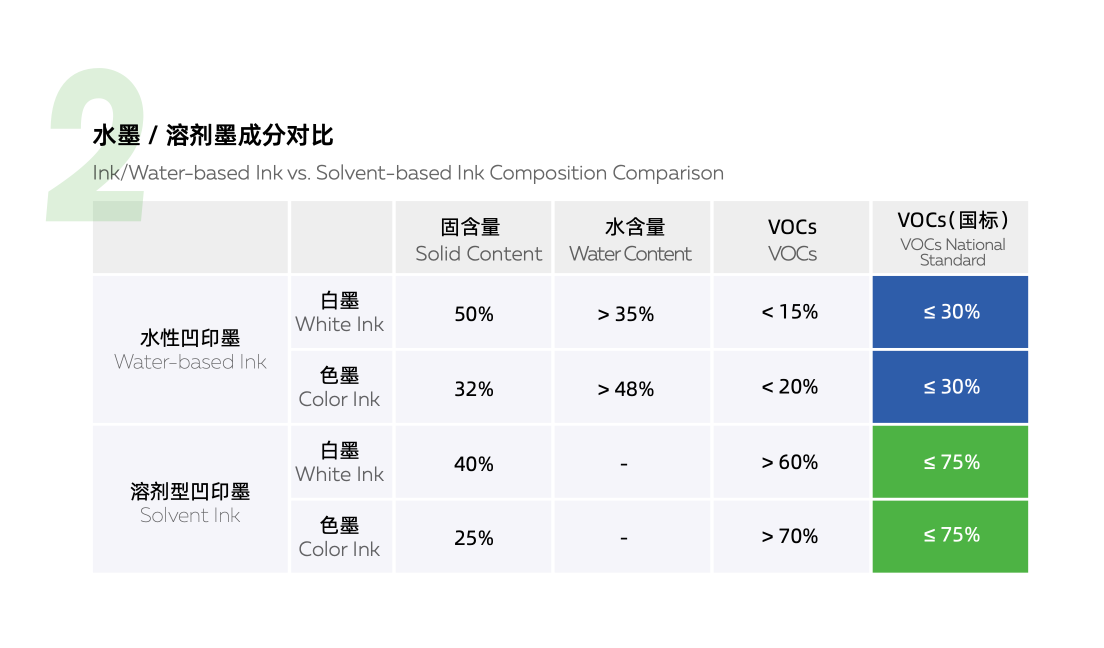

Compliance with safety regulations is non-negotiable when selecting a cold-seal ink supplier; after all, product safety directly impacts consumer health and satisfaction! Suppliers should adhere to local and international safety standards relevant to flexible packaging materials—including those governing VOC emissions—which are particularly important for environmentally conscious businesses.

To ensure compliance, ask potential suppliers for documentation proving that their inks meet industry regulations such as FDA approval or other relevant certifications pertinent to food-safe packaging applications. Being diligent about this aspect not only protects your customers but also safeguards your brand against legal issues down the line—a win-win situation!

By prioritizing ingredient sourcing quality, robust performance standards, and stringent compliance measures while learning how to choose a cold-seal ink supplier wisely, you'll set yourself up for success in the competitive world of flexible packaging.

Sustainability Practices

In today’s eco-conscious world, sustainability has become a crucial factor when considering how to choose a cold-seal ink supplier. Companies are increasingly looking for partners who prioritize environmentally friendly practices and products. By focusing on sustainable options, businesses can not only enhance their brand image but also contribute positively to the environment.

Eco-Friendly Products

When evaluating potential suppliers, it's essential to look for those that offer eco-friendly products. These products often use renewable resources and biodegradable materials, making them ideal for flexible packaging solutions. By incorporating cold seal heat-sensitive packaging made from sustainable materials, companies can reduce their carbon footprint while still meeting performance standards.

Moreover, an emphasis on eco-friendly products reflects a supplier's commitment to innovation and responsibility in the industry. It’s worth noting that many consumers are now more inclined to choose brands that demonstrate environmental consciousness in their product offerings. Therefore, ensuring that your cold seal ink supplier aligns with these values could lead to greater customer loyalty.

Commitment to Low VOCs

Another critical aspect of sustainability is a supplier's commitment to low volatile organic compounds (VOCs). High VOC levels can be detrimental to both the environment and human health, so choosing inks with low or no VOCs is essential for responsible packaging solutions. Cold seal heat-sensitive packaging that minimizes VOC emissions helps create safer working environments while reducing harmful pollutants released into the atmosphere.

Additionally, suppliers who prioritize low VOC formulations typically invest in research and development aimed at improving product safety and efficacy without sacrificing quality. This commitment not only benefits the planet but also enhances your brand’s reputation as an environmentally responsible entity in the marketplace. When asking how to choose a cold-seal ink supplier, consider their stance on VOC emissions as part of your evaluation process.

Case Study: Qinghe Chemical

Qinghe Chemical serves as an excellent case study in sustainable practices within the cold-seal ink industry. The company has developed a range of eco-friendly products specifically designed for flexible packaging applications while maintaining high performance standards—perfectly aligning with modern consumer expectations. Their dedication goes beyond just offering shrink wrapping ink; it includes rigorous ingredient sourcing practices that ensure all components meet strict environmental regulations.

Furthermore, Qinghe Chemical has implemented various initiatives aimed at reducing waste and energy consumption throughout its production processes. By showcasing their commitment through measurable sustainability practices, they have positioned themselves as leaders among cold-seal ink suppliers focused on innovation and environmental stewardship. This makes them an exemplary model for anyone wondering how to choose a cold-seal ink supplier who values sustainability alongside quality.

Pricing and Cost-Benefit Analysis

When it comes to selecting a cold-seal ink supplier, understanding pricing structures is essential for making an informed decision. Cold seal heat-sensitive packaging requires specific formulations that can vary significantly in price based on the quality of ingredients and the complexity of production processes. Therefore, it's crucial to dissect not just the upfront costs but also what those costs include—such as customization options or additional services like technical support.

Understanding Pricing Structures

Pricing structures for cold-seal inks can be complex and may differ from one supplier to another. Some suppliers might offer tiered pricing based on order volume, while others could have flat rates that encompass various product lines, including shrink wrapping ink. Additionally, be aware of any hidden fees associated with shipping or special handling that could inflate your overall cost.

In flexible packaging, where cold seal inks are commonly used, factors such as formulation complexity and performance characteristics can heavily influence pricing. For instance, a high-performance cold seal ink designed for demanding applications may cost more initially but could provide better adhesion and durability in the long run. Thus, understanding these nuances is key when evaluating how to choose a cold-seal ink supplier.

Long-Term Savings Considerations

While the initial investment in cold seal heat-sensitive packaging might appear steep, long-term savings should always be factored into your decision-making process. Quality inks can lead to fewer production disruptions due to failures or rework needed for subpar products—saving you time and money down the line. Moreover, investing in superior ingredients often results in enhanced performance characteristics that reduce waste during manufacturing.

For example, using premium shrink wrapping ink might mean higher upfront costs but will likely yield better sealing properties and lower failure rates during transit or storage. This translates into fewer product returns and complaints from customers—a win-win scenario! When assessing suppliers for flexible packaging solutions, remember that a higher initial cost can sometimes lead to greater financial efficiency over time.

Comparing Suppliers: Value vs. Cost

When comparing suppliers for cold-seal inks, it’s essential to look beyond just price; value plays a critical role as well. While one supplier may offer lower prices on their products like shrink wrapping ink, they may not match the performance or reliability of higher-priced alternatives from other manufacturers specializing in flexible packaging solutions. Always weigh factors such as customer service support and product consistency against their quoted prices.

To effectively evaluate how to choose a cold-seal ink supplier based on value versus cost, consider creating a matrix that includes all relevant criteria—quality of materials used in their formulations being paramount among them! By doing so, you'll gain clarity on which suppliers provide not only competitive pricing but also exceptional product offerings tailored to your specific needs in flexible packaging applications.

Conclusion

In the world of flexible packaging, selecting the right cold-seal ink supplier is crucial for ensuring product integrity and quality. Understanding how to choose a cold-seal ink supplier involves evaluating their experience, product quality, sustainability practices, and pricing structures. With the right supplier, businesses can leverage cold seal heat-sensitive packaging effectively while maximizing value.

Recap of Cold-Seal Ink Selection

Choosing the appropriate cold-seal ink supplier is not just about finding a good price; it’s about understanding what makes a supplier reliable and effective in delivering high-quality products. Key aspects such as industry reputation, customer testimonials, and compliance with safety regulations play pivotal roles in this decision-making process. Furthermore, considering benefits like eco-friendly options and low VOCs can enhance your packaging strategy while aligning with sustainability goals.

Final Thoughts on Supplier Relationships

Building a solid relationship with your cold-seal ink supplier can yield long-term benefits beyond just transactional exchanges. A reliable partner will not only provide consistent product quality but also offer insights into innovations in flexible packaging that can elevate your offerings. Remember that communication is key; regularly discussing needs and expectations fosters trust and ensures that both parties are aligned on goals.

Tips for Long-Term Satisfaction

To ensure long-term satisfaction when working with a cold-seal ink supplier, start by establishing clear expectations regarding performance standards and delivery timelines. Regularly assess their product offerings to stay updated on advancements in shrink wrapping ink technology that could benefit your operations. Finally, don’t hesitate to provide feedback; this collaborative approach will enhance both your relationship with the supplier and the overall quality of your flexible packaging solutions.