Introduction

Are you looking for a sustainable and efficient solution for your printing needs? Look no further than polyurethane water-based ink. This innovative ink offers numerous benefits, including eco-friendliness and cost-effectiveness. Waterborne polyurethane is the key to unlocking these advantages, providing a durable and versatile water-soluble resin for your printing projects. And when it comes to leading the way in water-based gravure inks, Qinghe Chemical is at the forefront of this revolutionary technology.

Benefits of Using Polyurethane Water-Based Ink

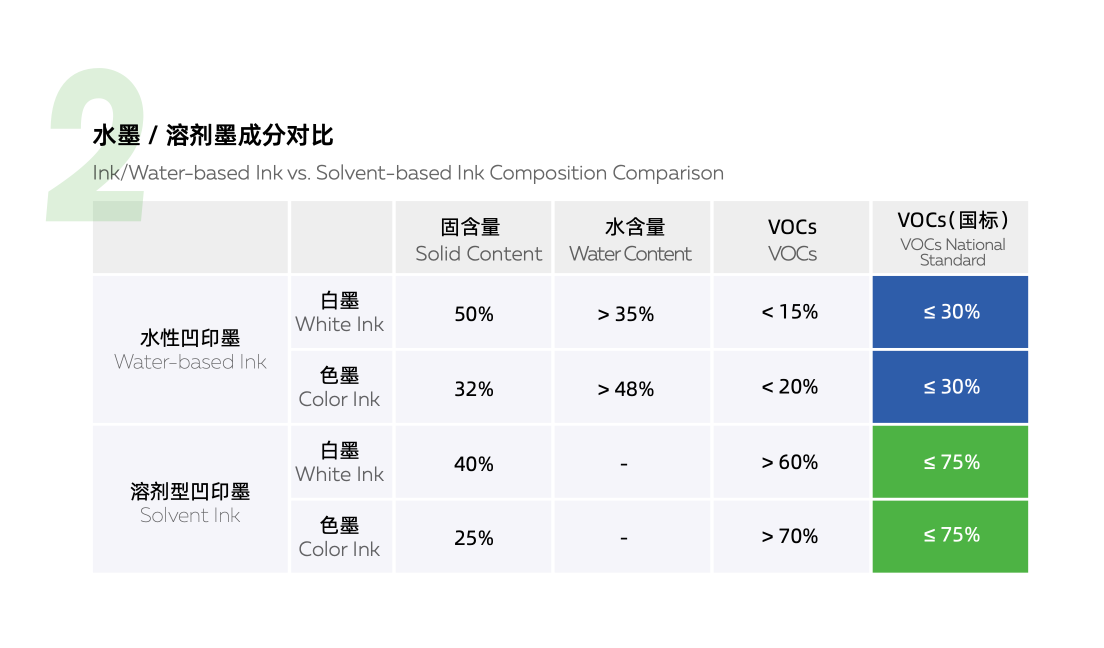

Polyurethane water-based ink offers numerous advantages for printers. It is an environmentally friendly option that delivers exceptional adhesion and flexibility across various substrates. Moreover, its low VOC content ensures a safer working environment.

In addition to its eco-friendliness, this type of ink boasts several practical benefits.

- Rapid drying: Polyurethane water-based ink dries swiftly, enhancing productivity and efficiency.

- Cost savings: Faster drying leads to increased output and lower production costs.

- Superior print quality: Quick drying minimizes smudging and smearing, leading to higher-quality prints.

Printers can contribute to environmental sustainability by choosing polyurethane water-based ink while improving their bottom line and producing exceptional results.

Key Features of Waterborne Polyurethane

Waterborne polyurethane is known for its exceptional durability and versatility. It can be used in various applications, from packaging to textiles, offering excellent resistance to abrasion and chemicals. Its ability to form strong bonds with different surfaces makes it an ideal choice for various printing projects.

Waterborne polyurethane is also valued for its environmentally friendly properties, as it emits low levels of volatile organic compounds (VOCs) during application. This makes it a popular choice for manufacturers looking to reduce their environmental impact without compromising performance. Waterborne polyurethane offers excellent UV resistance, making it suitable for outdoor applications such as automotive coatings and exterior signage. Its fast drying time and easy clean-up further contribute to its appeal in various industries.

Qinghe Chemical: Leading the Way in Water-Based Gravure Inks

Qinghe Chemical has established itself as a leader in developing and producing water-based gravure inks. Focusing on innovation and sustainability, they have pioneered the use of waterborne resins in printing, offering high-quality solutions that meet the demands of modern eco-friendly printing practices.

Qinghe Chemical's commitment to innovation and sustainability has led to the development of cutting-edge water-based gravure inks that offer superior performance without compromising environmental impact. By pioneering the use of waterborne resins in printing, they have set a new standard for eco-friendly printing practices, providing high-quality solutions that meet the demands of modern businesses and consumers alike.

Key benefits of Qinghe Chemical's water-based gravure inks include:

- Superior print quality: Delivering vibrant colors and sharp images.

- Reduced environmental impact: Lower VOC emissions and water consumption.

- Cost-effective: Often more economical than solvent-based inks.

- Safer workplace: Reduced exposure to harmful chemicals.

This forward-thinking approach has positioned Qinghe Chemical as a trailblazer in the industry, driving positive change and inspiring others to embrace more sustainable alternatives.

Qinghe Chemical's dedication to environmental responsibility and technological advancement makes them a preferred partner for businesses seeking high-quality, eco-friendly printing solutions.

Understanding Polyurethane Water Based Ink

What is Polyurethane Water-Based Ink?

Polyurethane water-based ink is a type of ink that uses water as a solvent, making it eco-friendly and safe for the environment. This type of ink is known for its high performance and durability, making it an ideal choice for various printing applications.

Polyurethane water-based ink offers several advantages over traditional solvent-based inks. Not only is it more environmentally friendly, but it also produces less odor and emits fewer volatile organic compounds (VOCs). This makes it a safer option for workers using the ink and the environment. Additionally, water-based inks are easier to clean up, reducing hazardous waste produced during printing.

Advantages of Using Waterborne Resins

Using waterborne resins in polyurethane water-based ink offers several advantages, including low VOC emissions, reduced environmental impact, and improved worker safety. Additionally, waterborne resins provide excellent adhesion to various substrates, making them suitable for different printing applications.

Furthermore, waterborne resins offer improved color development and stability, producing vibrant and long-lasting prints. This is essential for creating high-quality graphics and images that maintain their integrity over time. The ability of waterborne resins to resist yellowing and fading ensures that the printed materials remain visually appealing, even after prolonged exposure to light and environmental elements.

Key Components of Water-Based Pigment Ink

Water-based pigment ink consists of pigments dispersed in a water-soluble resin, which acts as the binder to hold the pigments together and adhere them to the printing surface. This type of ink also contains additives such as dispersants and defoamers to ensure proper dispersion and application properties.

In addition to the water-soluble resin and pigments, water-based pigment ink may also contain biocides to prevent microbial growth and extend the shelf life of the ink. These biocides help maintain the quality of the ink over time, ensuring that it remains effective and reliable for use in various printing applications. Furthermore, UV stabilizers may be included in the formulation to protect the ink from degradation caused by exposure to ultraviolet light, enhancing its durability and longevity.

Applications of Polyurethane Water Based Ink

Package Printing with Water-Based Inks

Polyurethane water-based inks are ideal for package printing because they are eco-friendly and sustainable. Using waterborne polyurethane, packaging materials can be printed with vibrant colors and excellent adhesion, ensuring high-quality packaging for various products. The water-soluble resin in these inks also allows for easy cleanup and reduces the environmental impact of package printing.

Furthermore, waterborne polyurethane inks offer excellent flexibility, making them perfect for printing on various packaging materials such as paper, cardboard, and plastic. This versatility allows for greater creativity in design and branding, ensuring that the packaging stands out on the shelves. Additionally, using water-based inks eliminates the need for harsh chemicals and solvents, creating a safer working environment for printing facilities.

Flexible Food Packaging with Waterborne Polyurethane

Waterborne polyurethane is a game-changer in the world of flexible food packaging. Using water-based resins ensures that the ink is safe for direct contact with food, making it an ideal choice for printing on materials used for food packaging. Additionally, these inks provide excellent flexibility and durability, ensuring the packaging maintains its integrity throughout the supply chain.

Waterborne polyurethane also offers environmental benefits, free from volatile organic compounds (VOCs) and hazardous air pollutants. This makes it a more sustainable option for food packaging, aligning with the increasing consumer demand for eco-friendly products. By choosing waterborne polyurethane for flexible food packaging, manufacturers can demonstrate their commitment to reducing their environmental impact while still delivering high-quality, safe products to consumers.

In-Printing and Compounding Benefits

Water-based pigment ink offers several benefits in in-printing and compounding processes. These inks provide excellent adhesion to various substrates, making them suitable for various applications, including labels, laminates, and more. Furthermore, their fast-drying properties contribute to increased efficiency in printing processes, resulting in reduced production time and costs.

In addition to their excellent adhesion and fast-drying properties, water-based pigment inks also offer environmental benefits. These inks are more eco-friendly than solvent-based inks, as they contain lower levels of volatile organic compounds (VOCs). This makes them a more sustainable option for printing and compounding processes, aligning with the industry's growing demand for environmentally friendly products and practices.

Benefits of Qinghe Chemical's Polyurethane Water-Based Inks

Qinghe Chemical is committed to sustainable printing practices with our polyurethane water-based inks. Our waterborne polyurethane formulations are designed to minimize environmental impact while delivering high-quality results. Using our water-soluble resins, you can reduce your carbon footprint without compromising performance.

Sustainable Printing with Qinghe Chemical

Our polyurethane water-based inks are formulated with waterborne resins that drastically reduce VOC emissions, making them eco-friendly for package printing and flexible food packaging. Our innovative technology allows you to achieve vibrant colors and sharp details while minimizing environmental harm.

Our water-based inks offer environmental benefits, cost, and safety advantages for your printing operations. By reducing the need for expensive ventilation systems and hazardous waste disposal, you can lower your production costs while ensuring a safer working environment for your employees. Additionally, our inks are easy to clean with water, eliminating the need for harsh solvents and reducing the risk of fire hazards in your facility.

Cost and Safety Advantages of Using Water-Based Inks

In addition to their environmental benefits, our water-based pigment inks offer cost and safety advantages. By eliminating the need for harsh solvents, you can create a safer work environment for your employees while reducing the risk of fire hazards. Furthermore, using water-based inks can save costs by streamlining production processes. Additionally, these inks have a faster drying time compared to solvent-based inks, allowing for increased productivity and efficiency in your printing operations. This means you can meet tight deadlines and fulfill customer orders more quickly, giving you a competitive edge in the market.

Environmental and Health Benefits

Choosing Qinghe Chemical's polyurethane water-based inks offers many benefits. Not only does it protect the environment, but it also prioritizes the health of workers and consumers.

By switching to our water-based inks, you can:

- Improve air quality and reduce health risks for your workers.

- Create safer packaging materials that protect consumers.

- Enhance your brand's reputation as environmentally and socially responsible.

With growing consumer awareness of the impact of packaging on the planet and human health, making eco-conscious choices can give your business a significant advantage.

Choose Qinghe Chemical and contribute to a healthier planet while boosting your brand image.

Qinghe Chemical: A Leader in Eco-Friendly Printing Solutions

In conclusion, Qinghe Chemical is a leader in eco-friendly printing solutions, offering a wide range of polyurethane water-based inks that provide exceptional quality and sustainability. Their innovative waterborne polyurethane technology revolutionizes the industry by offering cost-effective and environmentally friendly printing solutions.

Qinghe Chemical has established itself as a pioneer in developing waterborne resins and water-soluble resin technology, providing sustainable and high-performance options for package printing. Their commitment to eco-friendly practices and cutting-edge research makes them a top choice for businesses looking to reduce their environmental impact while maintaining superior print quality.

Qinghe Chemical's polyurethane water-based inks offer a range of advantages for package printing. These inks provide excellent adhesion to various substrates, including paper, cardboard, and plastic, ensuring durability and longevity for printed materials. Furthermore, the fast drying time of these inks increases production efficiency and reduces energy consumption, contributing to overall cost savings for businesses.

Advantages of Using Polyurethane Water-Based Inks

Polyurethane water-based inks offer a compelling combination of performance and sustainability benefits. These inks excel in adhesion, flexibility, and durability while maintaining an environmentally friendly profile.

Key advantages of polyurethane water-based inks include:

- Enhanced safety: Waterborne resins create a healthier working environment for printers by eliminating harmful solvents and VOCs.

- Vibrant colors: These inks produce vivid, eye-catching colors without compromising print quality.

- Customization: Polyurethane water-based inks offer unparalleled flexibility, enabling the creation of unique and distinctive packaging designs.

By harnessing the potential of waterborne resins, printers can deliver exceptional packaging solutions that captivate consumers and align with growing sustainability concerns.

Polyurethane water-based inks significantly advance packaging printing, providing a winning performance, safety, and aesthetic appeal formula.

The Future of Package Printing with Waterborne Resins

As the demand for sustainable packaging solutions continues to grow, the future of package printing lies with waterborne resins. With their ability to meet strict environmental regulations and deliver exceptional print quality, polyurethane water-based inks are poised to become the standard for eco-conscious packaging production.

With the increasing focus on reducing carbon footprint and minimizing environmental impact, waterborne resins offer a sustainable alternative to traditional solvent-based inks. By utilizing water as a carrier for the resin, these inks significantly reduce volatile organic compound (VOC) emissions during the printing process, contributing to cleaner air and a healthier work environment. This shift towards waterborne resins aligns with eco-conscious consumer preferences and helps packaging manufacturers meet stringent sustainability goals.