Introduction

Are you curious about shrink sleeve ink options and innovative solutions in the printing industry? Do you want to learn more about water-based inks and their benefits? In this article, we will delve into the world of shrink sleeve printing, explore alternative packaging solutions, and discuss the impact of inks and surface treatments on sustainable packaging.

Shrink Sleeve Ink Options

When it comes to shrink sleeve printing, the choice of ink is crucial. Understanding what ink is used for shrink sleeves and how to calculate them is essential for achieving high-quality results. We will also explore inkjet printing on shrink sleeve packaging and its advantages. In addition to traditional flexographic printing, digital inkjet printing offers the advantage of shorter setup times and the ability to produce smaller print runs more cost-effectively. This can be particularly beneficial for brands looking to test new packaging designs or run limited-time promotions without committing to large print quantities.

Qinghe Chemical's Innovative Solutions

Qinghe Chemical is at the forefront of providing innovative solutions for the printing industry. Their water-based gravure inks offer an eco-friendly alternative with low VOC emissions and enhanced work safety. We will delve into their commitment to green solutions and sustainable packaging.

Qinghe Chemical's water-based gravure inks not only provide a more environmentally friendly option, but they also offer superior print quality and color vibrancy. This means that businesses can enjoy the benefits of reduced environmental impact without sacrificing the visual appeal of their printed materials. Additionally, these inks are designed to adhere well to a variety of substrates, offering versatility and reliability for a wide range of printing applications.

Benefits of Water-based Inks

Water-based inks are gaining popularity due to their eco-friendly nature and cost-effective printing options. In addition to being environmentally friendly, water-based inks also offer vibrant and long-lasting colors, making them a popular choice for sustainable packaging solutions. With the increasing demand for eco-friendly packaging, brands are turning to water-based inks to meet consumer preferences while also reducing their environmental impact.

Understanding Shrink Sleeve Printing

Shrink sleeve printing is a popular method for packaging because it allows for 360-degree branding on a product. The ink used for shrink sleeves is crucial to ensure vibrant colors and high-quality graphics that can withstand the shrinking process. Water-based inks are often preferred for their eco-friendly properties, as they emit fewer volatile organic compounds (VOCs) compared to solvent-based inks.

What ink is used for shrink sleeves?

The ink used for shrink sleeves needs to have certain characteristics to ensure the best results. It should be able to adhere well to the plastic substrate, resist abrasion and scratches, and provide excellent color saturation. Water-based inks are an ideal choice as they offer these qualities while also being environmentally friendly.

The ink used for shrink sleeves plays a crucial role in the overall quality and appearance of the final product. In addition to its adhesion and color saturation properties, the ink must also be able to withstand the heat shrinking process without smudging or distorting the design. This requires a careful selection of ink formulations and drying processes to ensure that the printed image remains crisp and vibrant after application.

How do you calculate shrink sleeves?

Calculating the dimensions of a shrink sleeve can be a complex process due to the need to account for the material's shrinkage rate during printing and application. Factors such as container size, label design, and distortion caused by heat must be considered when determining the appropriate dimensions for a shrink sleeve.

Inkjet Printing on Shrink Sleeve Packaging

Inkjet printing has become increasingly popular for shrink sleeve packaging due to its ability to produce high-resolution images with vibrant colors. This method allows for greater flexibility in customization and shorter production runs, making it an attractive option for companies looking to create eye-catching packaging without large print volumes.

In addition to its flexibility and high-resolution capabilities, inkjet printing on shrink sleeve packaging also offers environmental benefits. With the ability to use water-based inks, this method reduces the use of harmful chemicals and solvents, making it a more sustainable option for packaging production. This aligns with the growing consumer demand for eco-friendly products and can enhance a company's brand image as environmentally conscious.

Qinghe's Water-based Gravure Inks

When it comes to shrink sleeve ink, Qinghe Chemical offers a game-changing eco-friendly solution with its water-based gravure inks. These inks are specifically designed to meet the demands of shrink sleeve printing, providing vibrant colors and excellent adhesion to various substrates. What's more, they are formulated with low VOC emissions, making them an environmentally friendly choice for packaging printing.

Eco-friendly Solution

Qinghe's water-based gravure inks are the perfect alternative for those seeking sustainable options for shrink sleeve printing. These inks are made from renewable resources and do not contain harmful chemicals, making them an eco-friendly choice for packaging applications. With their superior print quality and minimal impact on the environment, they are the go-to solution for conscious brands looking to reduce their carbon footprint.

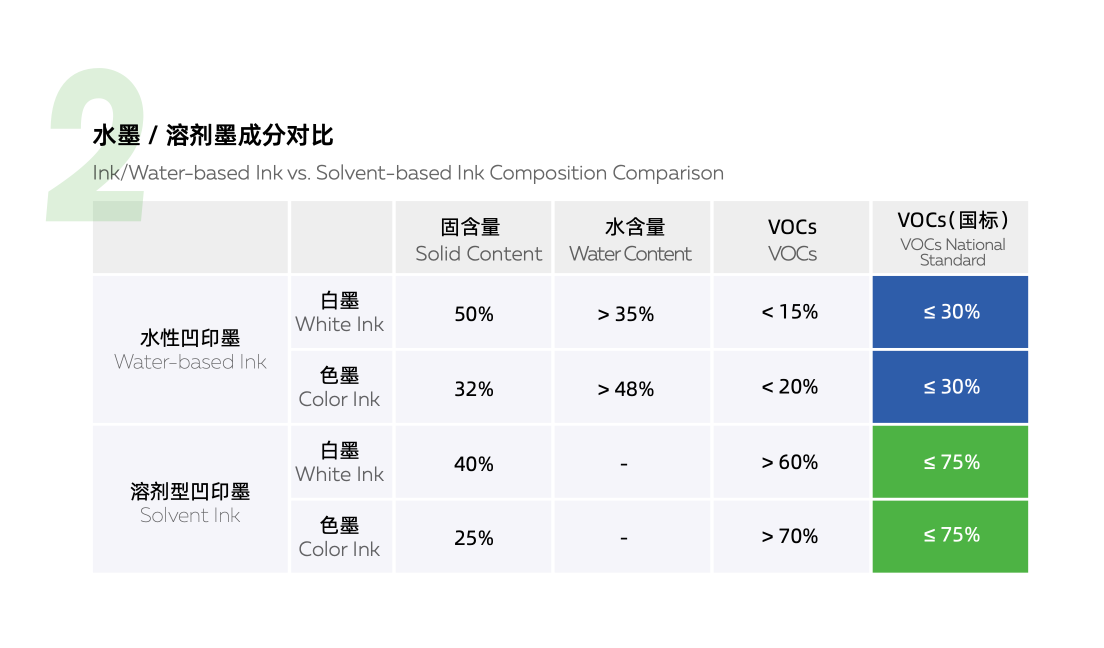

Low VOC Emissions

One of the key advantages of Qinghe's water-based gravure inks is their low VOC emissions. This means that during the printing process, these inks release significantly fewer volatile organic compounds into the atmosphere compared to traditional solvent-based inks. By choosing these low VOC emission inks, companies can contribute to a healthier and cleaner environment while still achieving high-quality shrink sleeve prints.

Enhanced Work Safety

In addition to being environmentally friendly, Qinghe's water-based gravure inks also prioritize work safety for printers and packaging manufacturers. These inks eliminate exposure to harmful chemicals commonly found in traditional solvent-based options, creating a safer working environment for employees. By choosing these innovative water-based gravure inks, companies can ensure the well-being of their workers while delivering top-notch shrink sleeve packaging.

The Impact of Inks and Surface Treatments

Inks and surface treatments play a crucial role in the sustainability of packaging solutions. Shrink sleeve ink options, such as water-based inks, offer eco-friendly alternatives to traditional solvent-based inks. These sustainable inks contribute to reducing the environmental impact of packaging production.

Sustainable Packaging Solutions

Shrink sleeve printing with water-based inks provides sustainable packaging solutions that are both visually appealing and environmentally friendly. By using eco-friendly inks, companies can reduce their carbon footprint and meet the increasing consumer demand for sustainable products. This shift towards sustainable packaging is essential for the future of the industry.

Cost-effective Printing Options

In addition to being environmentally friendly, water-based shrink sleeve inks also offer cost-effective printing options. These inks provide excellent adhesion properties, resulting in high-quality print finishes while reducing overall production costs. The cost-effectiveness of these inks makes them a practical choice for businesses looking to minimize expenses without compromising on quality.

Furthermore, water-based shrink sleeve inks are easy to work with, reducing the need for complex and expensive equipment. Their fast drying time also means quicker production turnaround, saving businesses time and money. This makes them a practical choice for companies looking to streamline their printing processes and meet tight deadlines without sacrificing quality.

Hazard-free Processing

Water-based shrink sleeve ink options contribute to hazard-free processing within manufacturing facilities. With low VOC emissions, these inks promote a safer working environment for employees while complying with strict health and safety regulations. This ensures that the entire production process is conducted responsibly and without harmful effects on workers or the environment.

By adopting water-based shrink sleeve ink options, businesses can achieve sustainable packaging solutions while benefiting from cost-effective printing and hazard-free processing practices.

Exploring Alternatives to Shrink Sleeves

As the demand for sustainable packaging solutions continues to grow, many companies are looking for alternatives to traditional shrink sleeves. One popular option is flexible packaging, which offers a more eco-friendly and cost-effective solution. By using inks and surface treatments that are compatible with flexible materials, companies can achieve vibrant and durable packaging without the need for shrink sleeves.

Sustainable Packaging Innovations

Sustainable packaging innovations are revolutionizing the industry by offering greener alternatives to traditional materials. By utilizing eco-friendly inks and surface treatments, companies can reduce their environmental impact while still achieving high-quality printing results. These innovations not only benefit the environment but also provide cost savings for businesses looking to adopt more sustainable practices.

Furthermore, sustainable packaging innovations are also contributing to reducing the carbon footprint of the industry. By using materials that are easily recyclable or biodegradable, companies can minimize waste and lessen their impact on landfills. This not only benefits the environment but also aligns with consumer demand for more eco-conscious products, giving businesses a competitive edge in the market.

Qinghe's Greener Printing Options

Qinghe Chemical is at the forefront of providing greener printing options for sustainable packaging solutions. Their water-based gravure inks offer a more environmentally friendly alternative to traditional solvent-based inks, reducing VOC emissions and enhancing work safety. By partnering with Qinghe, businesses can take advantage of these greener printing options to align with their sustainability goals.

In addition to being more environmentally friendly, Qinghe's water-based gravure inks also offer superior print quality, ensuring that businesses can maintain high standards for their packaging designs. The vibrant colors and sharp details achieved with these inks can help products stand out on the shelf, ultimately boosting sales and brand recognition. By choosing Qinghe's greener printing options, businesses can not only reduce their environmental impact but also enhance the visual appeal of their packaging.

Advantages of Flexible Packaging

Flexible packaging offers numerous advantages over traditional shrink sleeves, including reduced material usage, lower shipping costs, and improved product protection. By utilizing inks and surface treatments specifically designed for flexible materials, companies can achieve eye-catching designs while minimizing their environmental footprint. This shift towards flexible packaging not only benefits the planet but also provides a competitive edge in today's market.

By exploring alternatives to shrink sleeves and embracing sustainable packaging innovations like flexible materials and eco-friendly inks from Qinghe Chemical, businesses can make significant strides towards reducing their environmental impact while maintaining high-quality printing standards.

Conclusion

Sustainable Packaging Solutions with Qinghe Chemical

In conclusion, Qinghe Chemical offers a wide range of eco-friendly shrink sleeve ink options that are not only cost-effective but also sustainable. Their water-based gravure inks provide low VOC emissions and enhanced work safety, making them the perfect choice for environmentally conscious businesses looking for shrink sleeve printing solutions.

Eco-friendly Printing for the Future

As the demand for sustainable packaging solutions continues to grow, Qinghe's commitment to green solutions sets them apart as a leader in the industry. Their innovative water-based inks and surface treatments offer a greener alternative to traditional shrink sleeves, ensuring a brighter future for eco-friendly printing practices.

Qinghe's Commitment to Green Solutions

With a focus on reducing environmental impact and promoting sustainability, Qinghe Chemical is dedicated to providing high-quality shrink sleeve ink options that meet the growing demand for eco-friendly packaging solutions. Their dedication to innovation and green printing practices makes them a trusted partner for businesses seeking sustainable alternatives.