Introduction

Welcome to the exciting world of water-based coatings! This comprehensive guide will delve into the fascinating realm of water coating technology, explore its advantages over solvent-based coatings, and examine its positive environmental impact.

Understanding Water-Based Coatings

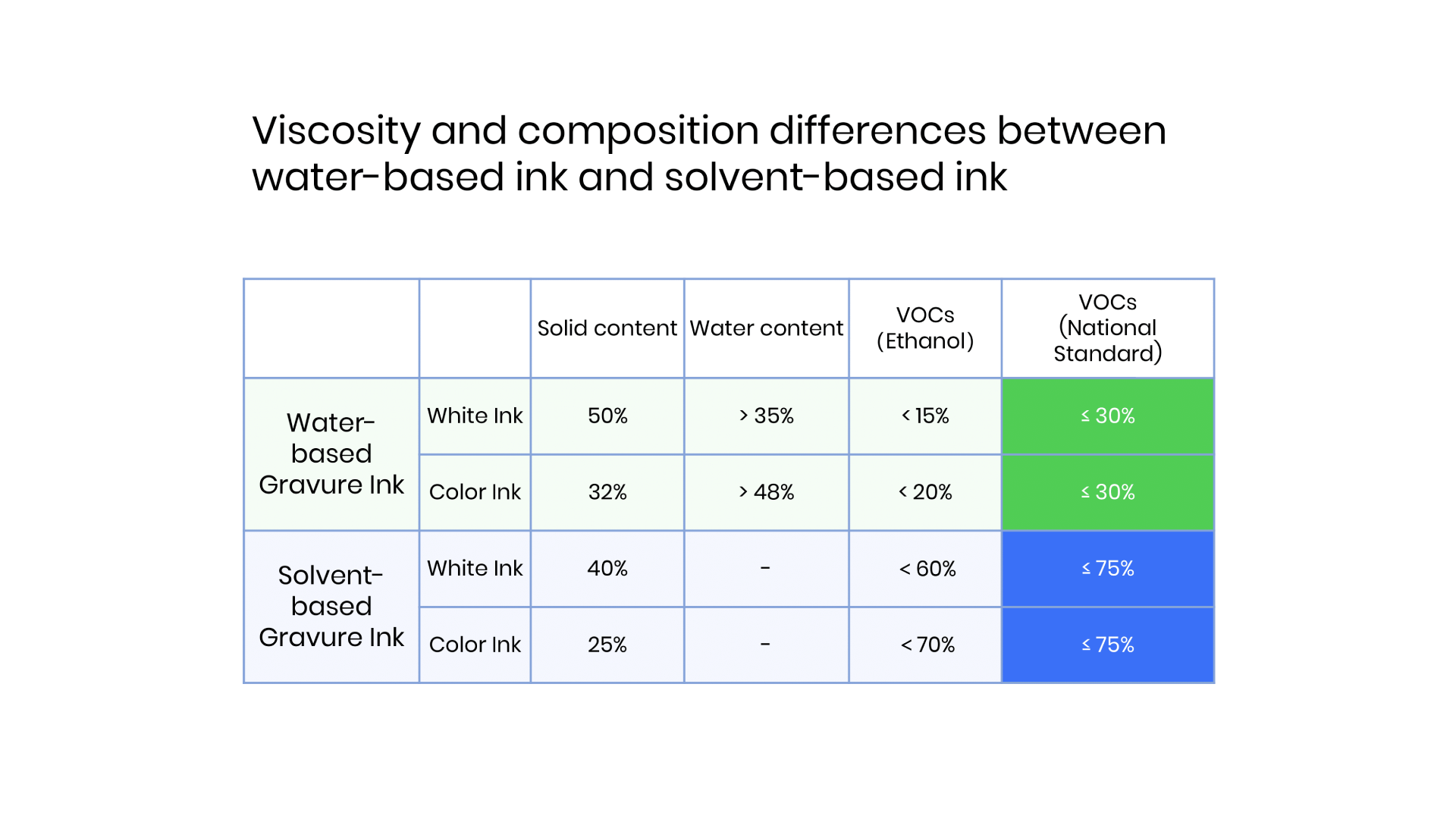

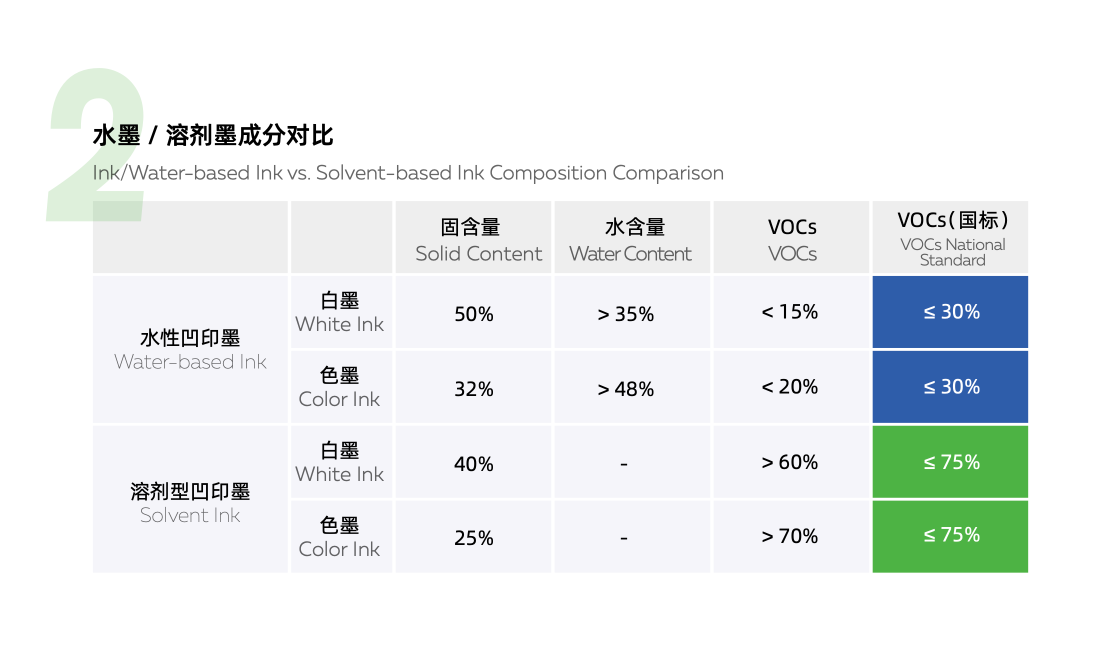

Water-based coatings are innovative solutions that use water as a carrier for the resin and other additives. These coatings offer many benefits, including low VOC emissions, improved health and safety features, and cost efficiency.

Water-based coatings are also known for their fast drying times, which can help increase productivity and reduce project turnaround times. This makes them an ideal choice for industries that require quick and efficient coating applications, such as automotive manufacturing and metal fabrication. Additionally, water-based coatings are easy to clean with just soap and water, eliminating the need for harsh chemical solvents and reducing environmental impact.

Exploring Solvent-Based Coatings

On the other hand, solvent-based coatings have traditionally been popular due to their quick drying time, durability, and application flexibility. However, they come with environmental concerns due to high VOC emissions and potential health hazards.

Solvent-based coatings have long been favored for their quick drying time, durability, and versatility in application. However, these advantages come at a cost to the environment and human health. The high levels of volatile organic compounds (VOCs) released during the application and drying of solvent-based coatings contribute to air pollution and can harm respiratory health. Additionally, the potential for exposure to harmful chemicals in these coatings poses risks to both workers and consumers. As awareness of environmental impact and health concerns continues to grow, there is an increasing demand for alternative coating options that offer similar benefits without the drawbacks of solvent-based formulations.

The Environmental Impact

The environmental impact of coatings cannot be overlooked. Water-based coatings have gained popularity due to their reduced VOC emissions and eco-friendly nature. They are paving the way for a sustainable future in the coating industry.

Now that we've set the stage for our exploration of water-based coatings and their benefits over solvent-based alternatives, let's dive into the specific advantages of water coating technology in various applications, such as paper cups and metal surfaces.

The Advantages of Water-based Coatings

Water-based coatings offer numerous advantages that make them popular in various industries. From reduced VOC emissions to cost efficiency, they provide a sustainable and effective solution for many applications.

1. Reduced VOC Emissions

One key advantage of water-based coatings is their significantly lower levels of volatile organic compounds (VOCs). This reduction in harmful emissions makes them an environmentally friendly option, contributing to better air quality and overall health.

Water-based coatings also offer health and safety benefits to those who work with them. Unlike solvent-based coatings, water-based options do not release harmful fumes or toxins into the air during application. This means painters and other professionals can work in a safer environment, reducing their risk of exposure to potentially hazardous chemicals. Additionally, water-based coatings are easier to clean up, minimizing the potential for accidents or injuries in the workplace.

2. Health and Safety Benefits

In addition to being eco-friendly, water-based coatings also offer health and safety benefits for workers and end-users. With minimal exposure to toxic chemicals, these coatings provide a safer working environment and reduce potential health risks associated with solvent-based alternatives.

3. Cost Efficiency

Water-based coatings are known for their cost efficiency, offering a lower overall cost than solvent-based options. With reduced waste, faster drying times, and less need for specialized equipment, these coatings provide a budget-friendly solution without compromising quality or performance.

Now that we've explored the advantages of water-based coatings, let's delve into the benefits of using water-based coatings for paper cups.

The Benefits of Solvent-based Coatings

Solvent-based coatings offer several advantages, making them a popular choice in various industries. One of the key benefits is their quick drying time, which allows for faster production and turnaround times. This is particularly advantageous in high-volume manufacturing settings where efficiency is paramount. Additionally, solvent-based coatings are known for their durability, providing long-lasting protection against wear and tear. This makes them an ideal option for applications that require a tough, resilient finish. Furthermore, these coatings offer excellent application flexibility, allowing them to be used on various surfaces and substrates.

1. Quick Drying Time

Solvent-based coatings are prized for their rapid drying properties, enabling manufacturers to streamline production processes and meet tight deadlines without compromising quality. Achieving a fast turnaround time is crucial in industries such as automotive and industrial manufacturing, where efficiency is essential for meeting consumer demand.

2. Durability

Solvent-based coatings' durability makes them an attractive choice for applications that require long-term protection against environmental factors such as moisture, heat, and abrasion. Whether used on metal surfaces or plastic components, these coatings provide a robust barrier that extends the lifespan of the coated materials.

3. Application Flexibility

Another notable advantage of solvent-based coatings is their versatility in terms of application. From spray coating to dip coating methods, these coatings can be applied using various techniques to suit the specific requirements of different industries and products.

Moreover, solvent-based coatings offer the advantage of being easily customizable to meet specific industry needs. Whether it's the automotive, aerospace, or furniture industry, these coatings can be tailored to provide the desired level of protection and aesthetic appeal. This flexibility allows for greater innovation and creativity in product design and development, making solvent-based coatings a preferred choice for manufacturers looking to differentiate their offerings in the market.

Understanding the benefits of solvent-based coatings, such as quick drying time, durability, and application flexibility, it's clear why they remain a popular choice across many industries despite growing interest in water-based alternatives.

Water-based Coating for Paper Cup

As the demand for eco-friendly packaging grows, water-based coatings for paper cups have become increasingly popular. Qinghe Chemical has pioneered in this field, developing innovative solutions that provide excellent water resistance without compromising environmental sustainability.

Qinghe Chemical’s Impact

Qinghe Chemical has revolutionized the paper cup industry with its water-based coating technology. Replacing traditional solvent-based coatings with eco-friendly alternatives has significantly reduced VOC emissions and minimized the environmental impact of paper cup production.

Environmental Benefits

Water-based coatings offer a more sustainable solution for paper cups, benefiting the environment in several ways:

- Reduced Pollution: Water-based coatings are nontoxic and biodegradable, minimizing environmental impact compared to solvent-based alternatives, which can release harmful chemicals during production and disposal.

- Lower Energy Consumption: Water-based coatings require less energy and resources than solvent-based ones, leading to a smaller carbon footprint for paper cup manufacturing.

- Enhanced Recyclability: Water-based coatings make paper cup recycling easier, diverting waste from landfills and promoting a circular economy.

By choosing water-based coated paper cups, companies can demonstrate their commitment to sustainability and cater to environmentally conscious consumers. This shift towards eco-friendly packaging is a win for businesses and the planet.

Cost and Performance Comparison

In addition to their environmental advantages, water-based coatings offer cost efficiency and comparable performance to solvent-based options. The initial investment in transitioning to these coatings is offset by long-term savings due to reduced waste disposal costs and improved overall product quality.

Water Coating Film vs. Solvent Coating Film

Performance Evaluation

When comparing water coating film to solvent coating film, it's clear that water-based coatings offer excellent performance in adhesion, flexibility, and resistance to abrasion. Water coating films have been proven to provide superior protection and durability, making them an ideal choice for various applications.

Environmental Impact

The environmental impact of water coating film is significantly lower than that of solvent coating film. With reduced VOC emissions and minimal hazardous air pollutants, water-based coatings contribute to a healthier and more sustainable environment. This makes them the preferred choice for eco-conscious consumers and businesses alike.

Furthermore, water-based coatings are also known for their durability and resistance to yellowing, making them a practical and long-lasting option for various applications. This reduces the need for frequent reapplications and minimizes waste and resource consumption in the long run. Additionally, the versatility of water-based coatings allows for a wide range of finishes and effects, providing ample choices for consumers without compromising on environmental responsibility.

Market Demand

As the demand for eco-friendly solutions continues to rise, the market for water coating film is experiencing significant growth. Consumers increasingly seek products that align with their environmental values, driving the demand for sustainable coatings across various industries. This trend positions water-based coatings as a key player in the market's future.

The demand for water-based coatings is also driven by the increasing emphasis on workplace health and safety. With stricter regulations on volatile organic compounds (VOCs) and other harmful chemicals, industries are turning to water-based coatings as a safer alternative. This shift benefits the environment and improves employees' working conditions, making it a win-win situation for all stakeholders involved.

Water Resistant Coating for Metal

Product Applications

Water resistant coatings for metal have a wide range of applications, from outdoor furniture and automotive parts to industrial machinery and marine equipment. These coatings provide long-lasting protection against corrosion, rust, and environmental damage, making them essential for various industries.

Durability Comparison

Compared to solvent-based coatings, water resistant coatings for metal offer superior durability and long-term performance. These coatings form a strong barrier against moisture and harsh weather conditions, ensuring that the metal surfaces remain intact and protected for an extended period.

Additionally, water resistant coatings are environmentally friendly, as they do not contain harmful solvents or volatile organic compounds (VOCs) that can contribute to air pollution. This makes them a more sustainable choice for metal protection, aligning with the growing trend of eco-conscious manufacturing and construction practices. By choosing water resistant coatings, businesses can demonstrate their commitment to reducing their environmental impact while achieving superior durability for their metal surfaces.

Environmental Considerations

In addition to their exceptional durability, water resistant coatings for metal are also environmentally friendly. With reduced VOC emissions and minimal impact on air quality, these coatings contribute to sustainable manufacturing practices while providing top-notch protection for metal surfaces.

Furthermore, using water resistant coatings for metal can also contribute to energy savings in the long run. By protecting metal surfaces from corrosion and degradation, these coatings help extend the lifespan of metal components, reducing the need for frequent replacements and the associated energy consumption. This benefits manufacturers by lowering maintenance costs and contributes to overall energy efficiency and resource conservation.

Make the Switch: Benefits of Water-based Coatings

Water-based coatings offer many benefits, from reduced VOC emissions to cost efficiency and health and safety advantages. Switching to water-based coatings is beneficial not only for the environment but also for businesses looking to improve their bottom line. With Qinghe Chemical leading the way in eco-friendly coatings, the future looks bright for sustainable and high-performance coating solutions.

Switching to water-based coatings is smart for businesses looking to reduce their environmental impact and improve workplace safety. With reduced VOC emissions, lower health risks, and cost efficiency, water-based coatings present a compelling case for transitioning away from solvent-based alternatives.

Qinghe Chemical: Leading the Way

Qinghe Chemical has been developing innovative water-based coating solutions, particularly in the paper cup industry. Their impact on reducing environmental footprint while maintaining high performance is commendable, setting a standard for other companies to follow in embracing eco-friendly practices.

The Future of Eco-Friendly Coatings

The future of coatings lies in eco-friendly solutions like water-based coatings that offer exceptional performance without compromising sustainability. As consumer demand for environmentally conscious products continues to rise, companies like Qinghe Chemical are paving the way for a greener future in the coating industry.