Introduction

In the world of package printing, the choice of ink plays a crucial role in determining the quality and durability of the final product. Water-based flexographic inks have emerged as a game-changer in this industry, offering a range of benefits that reshape the way labels and prints are produced. Understanding the importance, advantages, and impact of water-based flexographic inks makes it clear why they are revolutionizing package printing.

The Importance of Water-Based Flexographic Inks

Due to their environmental benefits, water-based flexographic inks are increasingly popular in the printing industry. They offer a more sustainable alternative to traditional solvent-based inks, making them a valuable choice for eco-conscious businesses.

Here are some key advantages of using water-based flexographic inks:

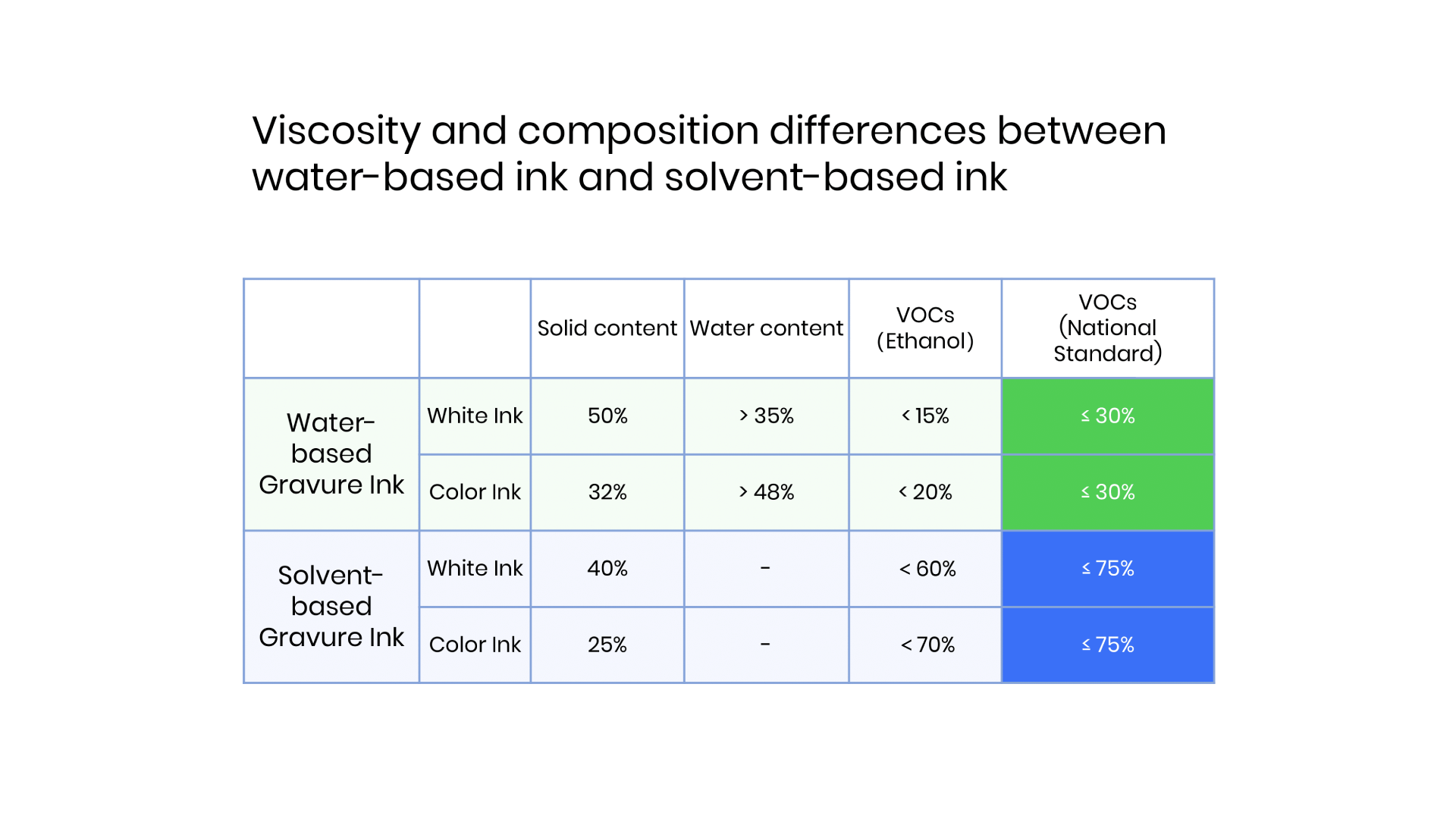

- Environmentally friendly: Water-based inks significantly reduce volatile organic compounds (VOCs) use compared to solvent-based inks. This minimizes air pollution and creates a safer work environment for printing press operators.

- Vibrant and consistent colors: Water-based inks deliver high-quality printing with excellent color reproduction, ensuring visually appealing packaging and labels.

- Sustainable choice: Water-based inks are a responsible alternative to traditional inks, promoting a more eco-friendly printing process and contributing to a circular economy.

Water-based flexographic inks offer a compelling combination of environmental responsibility and superior print quality, making them a valuable asset for sustainable packaging production.

Advantages of Using Water-Based Flexographic Inks

Water-based flexographic inks provide a compelling alternative to traditional solvent-based inks, offering numerous advantages beyond just environmental considerations.

Here are some key benefits of using water-based flexographic inks:

- Enhanced Print Quality: Water-based inks deliver exceptional clarity and sharpness, producing high-quality prints with vivid details.

- Superior Color Reproduction: These inks produce a wider color gamut, enabling accurate and vibrant representation of the intended colors.

- Improved Adhesion Properties: Water-based inks demonstrate superior adhesion to various substrates, ensuring the longevity and durability of the printed image.

In conclusion, water-based flexographic inks combine environmental responsibility with superior print quality and performance, making them a valuable choice for various printing applications.

Enhancing Package Printing Quality with Water-Based Flexographic Inks

Water-based flexographic inks have raised the bar for package printing quality by providing better color vibrancy, sharper details, and increased resistance to fading or smudging. With these inks, package printers can elevate their standards and meet the growing demands for superior print results.

Understanding Water-Based Flexographic Inks

Water-based flexographic inks are used for printing labels and packaging materials. Unlike traditional solvent-based inks, they use water as the primary solvent, making them more environmentally friendly and safer to use. These inks are commonly used in flexographic printing, a popular method for producing high-quality prints on various substrates.

What are Water-Based Flexographic Inks?

Water-based flexographic inks are specifically formulated for flexographic printing, which involves transferring ink onto a substrate using flexible plates. These inks contain pigments or dyes dispersed in water and other additives to improve print quality and adhesion. They are designed to dry quickly and produce vibrant, color-accurate prints on different packaging materials.

Comparing Water-Based Flexographic Inks with Other Types

Compared to other types of printing ink, such as UV printing or screen press ink, water-based flexographic inks offer distinct advantages. They are known for their ability to produce sharp, high-resolution images with excellent color reproduction on various substrates. Additionally, these inks do not emit harmful volatile organic compounds (VOCs) like solvent-based ones, making them a safer and more sustainable choice.

Key Features of Water-Based Flexographic Inks

Water-based flexographic inks are gaining popularity in the printing industry due to their environmental benefits and improved performance. These inks offer several key advantages over traditional solvent-based inks:

- Superior Adhesion: They adhere well to various packaging materials, including paper, cardboard, and flexible films, ensuring vibrant and long-lasting prints on a wider range of surfaces.

- Excellent Lightfastness: Water-based inks exhibit superior resistance to fading caused by sunlight exposure. This ensures that the printed labels and packaging maintain their visual appeal throughout their shelf life.

- Enhanced Customizability: These inks can be easily customized to meet specific color requirements without compromising print quality. This allows for greater flexibility in creating unique and eye-catching designs.

Water-based flexographic inks offer a sustainable and versatile solution for various printing applications, making them a preferred choice for eco-conscious businesses and industries.

Benefits of Using Water-Based Flexographic Inks

1. Environmental Advantages

Water-based flexographic inks offer significant environmental benefits, free from volatile organic compounds (VOCs) and hazardous air pollutants (HAPs). This makes them a safer and more sustainable option for package printing, reducing the carbon footprint and promoting eco-friendly practices within the industry.

In addition to being environmentally friendly, water-based flexographic inks also offer improved print quality. These inks provide vibrant and consistent colors, resulting in sharp and high-resolution images on packaging materials. The superior adhesion and fast drying time of water-based inks contribute to a flawless finish, enhancing the overall visual appeal of the printed products. This meets the demand for high-quality packaging and reflects positively on the brand's image.

2. Improved Print Quality

When it comes to label and print quality, water-based flexographic inks excel in delivering vibrant and consistent colors. Their ability to produce fine details and smooth gradients enhances the overall visual appeal of packaging, making them a preferred choice for brands looking to make a lasting impression on consumers.

Water-based flexographic inks also offer improved adhesion to various substrates, ensuring that labels and packaging maintain their vibrant colors and crisp details throughout the product's lifespan. This durability is especially important for products exposed to moisture or other environmental factors, providing brands with the assurance that their packaging will continue to make a strong visual impact on consumers. Additionally, the fast-drying nature of water-based inks contributes to increased efficiency in the printing process, allowing for quicker turnaround times without compromising print quality.

3. Cost-Effectiveness and Efficiency

In addition to their environmental advantages and superior print quality, water-based flexographic inks offer cost-efficiency and production-efficiency benefits. With faster drying times, reduced waste, and minimal maintenance requirements, these inks contribute to streamlined printing processes, ultimately resulting in cost savings for manufacturers.

Furthermore, water-based flexographic inks require less energy to dry than solvent-based inks, reducing production costs and lowering carbon emissions. This makes them a more sustainable and cost-effective option for manufacturers looking to minimize their environmental impact while maximizing their bottom line. Additionally, the minimal maintenance requirements of water-based inks mean less downtime for equipment servicing, allowing for continuous and efficient production runs.

Application of Water-Based Flexographic Inks in Package Printing

Water-based flexographic inks have revolutionized the package printing industry, especially in terms of color reproduction. These inks offer vibrant print colors, allowing for stunning label and print designs that captivate consumers. Water-based flexographic inks ensure that every print color pops with exceptional clarity and precision, whether for food packaging or product labels.

Enhanced Color Reproduction

With water-based flexographic inks, package printing reaches new heights of visual appeal. The ink's ability to accurately reproduce colors results in eye-catching packaging that stands out on the shelves. Whether it's a bold logo or intricate design elements, these inks bring out the true essence of every print color, elevating the overall aesthetic of the packaging. Furthermore, the adhesion properties of these inks ensure that the colors stay vibrant and true to form, even after prolonged exposure to various environmental factors. This durability is essential for maintaining the integrity of the packaging and preserving its visual impact.

Adhesion and Durability

In addition to stunning print color, water-based flexographic inks offer exceptional adhesion and durability. This means that labels and prints retain their vividness and integrity even after prolonged use or exposure to various environmental factors. The ink's ability to maintain its quality ensures that package printing remains visually striking throughout its lifecycle. Furthermore, the superior adhesion of these inks reduces the risk of peeling or fading, providing a reliable solution for brands looking to maintain a consistent and professional image on their packaging. This level of durability also contributes to cost savings as it minimizes the need for frequent reprints or replacements due to wear and tear.

Meeting Regulatory Requirements

Water-based flexographic inks are designed to meet stringent regulatory requirements for packaging materials. Focusing on safety and compliance, these inks provide assurance that package printing adheres to industry standards and regulations. This makes them an ideal choice for brands looking to ensure their packaging meets all necessary guidelines.

Water-based flexographic inks also benefit from being environmentally friendly, as they contain lower levels of volatile organic compounds (VOCs) than traditional solvent-based inks. This aligns with the growing consumer demand for sustainable packaging and helps brands reduce their environmental impact. By choosing water-based flexographic inks, companies can demonstrate their commitment to eco-friendly practices and appeal to environmentally conscious consumers.

Addressing Common Concerns about Water-Based Flexographic Inks

Overcoming Challenges in Transitioning

Transitioning to water-based flexographic inks may seem daunting, but printers can effectively navigate the shift with the right guidance and support. Training programs and resources are available to help operators understand the nuances of water-based inks and optimize their printing processes. By embracing this change, printers can unlock sustainable benefits while maintaining exceptional print quality.

Addressing Misconceptions

One common misconception about water-based flexographic inks is that they lack vibrancy and color intensity compared to other ink types. However, advancements in formulation have enabled these inks to deliver rich, vibrant colors that meet or exceed industry standards. Additionally, innovations in ink chemistry have addressed concerns about adhesion and durability, ensuring that water-based flexographic inks are a reliable choice for package printing.

Testimonials from Industry Professionals

Industry professionals who have switched to water-based flexographic inks have reported significant improvements in print quality and environmental impact. Their testimonials highlight the ease of transitioning to these inks and the positive outcomes they have experienced, dispelling any doubts about their effectiveness. These firsthand accounts serve as compelling evidence of the value of water-based flexographic inks in package printing.

Industry professionals who have switched to water-based flexographic inks have also noted their cost-effectiveness compared to traditional solvent-based options. Not only do water-based inks produce higher-quality prints, but they also require less maintenance and cleaning, resulting in reduced operational costs for packaging companies. This financial benefit adds another layer of appeal to the already impressive list of advantages water-based flexographic inks offer.

Future Trends and Innovations in Water-Based Flexographic Inks

As the demand for sustainable and eco-friendly packaging solutions continues to rise, the formulation of water-based flexographic inks is undergoing significant advancements. Manufacturers are investing in research and development to create inks that offer improved color vibrancy, faster drying times, and enhanced adhesion properties, catering to the evolving needs of the packaging industry.

Advancements in Formulation

With a focus on reducing environmental impact and improving print quality, advancements in water-based flexographic ink formulation are driving innovation in the industry. New additives and resins are being introduced to enhance ink performance, resulting in sharper print colors, better ink transfer, and increased flexibility for label and package printing applications.

The advancements in water-based flexographic ink formulation also contribute to the development of sustainable packaging solutions. By reducing harmful chemicals and volatile organic compounds (VOCs), these new formulations align with the growing demand for eco-friendly packaging options. This shift towards more sustainable inks is beneficial for the environment and presents an opportunity for brands to enhance their corporate social responsibility efforts and appeal to environmentally conscious consumers.

Impact on Sustainable Packaging

The shift towards water-based flexographic inks is pivotal in promoting sustainable packaging practices. These eco-friendly inks reduce volatile organic compound (VOC) emissions, minimize waste generation, and support efforts to create recyclable packaging materials. As brands prioritize sustainability, using water-based flexographic inks is a key differentiator for environmentally conscious packaging solutions.

Role in Digital Printing Technologies

Water-based flexographic inks also influence digital printing technologies by enabling high-quality print outputs with reduced environmental impact. Their compatibility with digital presses allows for seamless integration into modern printing processes, offering enhanced color accuracy and improved efficiency for on-demand label and package printing.

Water-based flexographic inks also drive innovation in digital printing technologies by offering the ability to print on a wider range of substrates, including non-absorbent materials such as plastics and metallic foils. This versatility opens up new packaging and label design possibilities, allowing for more creative and eye-catching product presentations. With the ability to produce vibrant, high-resolution prints on these diverse surfaces, digital presses equipped with water-based flexographic inks are poised to revolutionize the packaging industry.

Remember to stay ahead of industry trends when using keywords like flexographic ink, printing with ink, UV printing, label, print, etc., so keep an eye on emerging developments as you continue your content creation journey!

Elevate Package Printing Standards with Water-Based Flexographic Inks

Water-based flexographic inks are revolutionizing the package printing industry by elevating printing standards and embracing sustainable practices. With their vibrant colors and enhanced print quality, water-based flexographic inks set a new label and package printing benchmark. As more companies recognize the environmental and cost-effective benefits of using water-based flexographic inks, the industry is poised for a significant shift toward sustainable packaging solutions.

Water-based flexographic inks have raised the bar for package printing standards, offering unparalleled color reproduction and print clarity. By utilizing these innovative inks, companies can ensure their packaging stands out on the shelves, effectively capturing consumers' attention with vibrant and eye-catching designs. The superior adhesion and durability of water-based flexographic inks also contribute to printed labels and packaging quality.

Embracing Sustainable Practices in Package Printing

Water-based flexographic inks offer a greener alternative to traditional solvent-based inks in an era where sustainability is paramount. Companies can reduce their environmental footprint by switching to these eco-friendly inks, aligning with consumer demands for environmentally conscious products. Embracing sustainable practices benefits the environment and enhances brand reputation, demonstrating a commitment to responsible packaging solutions.

The Future of Water-Based Flexographic Inks in Package Printing Industry

As advancements in ink formulation and digital printing technologies continue, the future looks promising for water-based flexographic inks. These innovations will further enhance color accuracy, print speed, and overall efficiency, solidifying their role as a leading choice for package printing. With an increasing emphasis on sustainable packaging solutions, water-based flexographic inks are poised to play a pivotal role in shaping the future of the package printing industry.