Introduction

When it comes to the world of printing, the choice of ink is crucial for achieving high-quality results. Water-based flexographic inks have emerged as a game-changer, offering a sustainable and environmentally friendly alternative to traditional solvent-based inks. These inks have gained immense importance in the printing industry due to their eco-friendly nature and superior print quality.

Importance of Water-Based Flexographic Inks

The printing industry is undergoing a significant shift towards environmentally friendly practices. Water-based flexographic inks are at the forefront of this revolution, offering a sustainable alternative to traditional solvent-based inks. Here's why water-based flexographic inks are gaining importance:

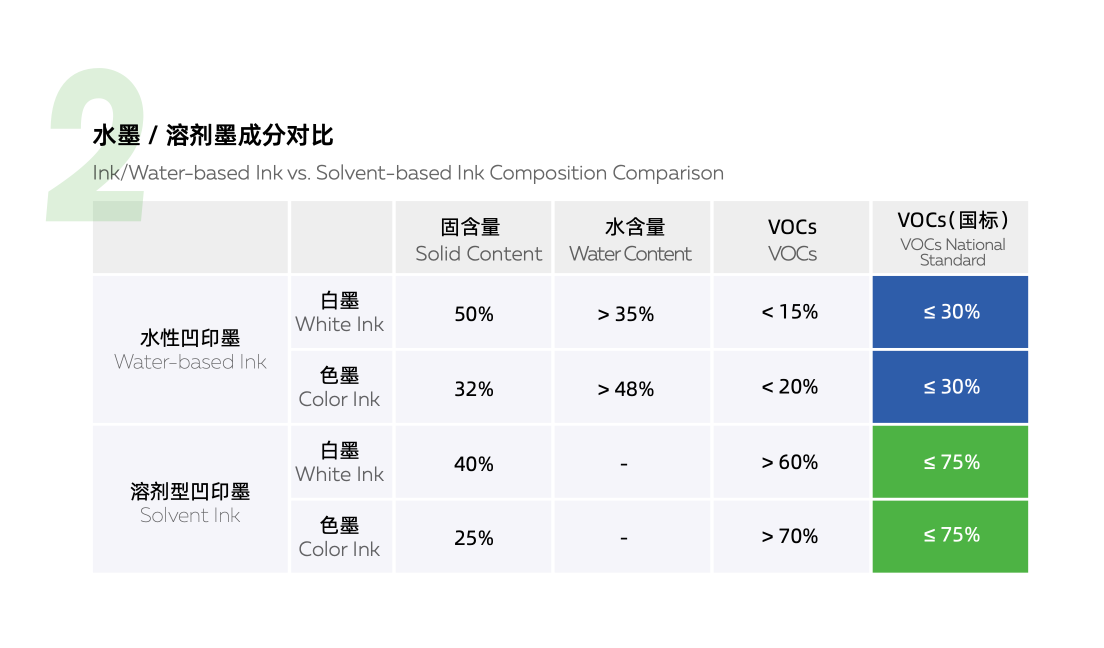

- Reduced Environmental Impact: Water-based inks significantly minimize Volatile Organic Compound (VOC) emissions compared to solvent-based inks. VOCs contribute to smog and air pollution, and reducing them is crucial for protecting air quality and human health.

- Safer Work Environment: Water-based inks pose fewer health risks to printing press operators due to lower levels of harmful chemicals. This creates a safer working environment by minimizing exposure to hazardous substances.

- Sustainable Material Use: Water is a readily available and renewable resource, making water-based inks a more sustainable than inks reliant on petroleum-derived solvents.

- Energy Efficiency: The drying process for water-based inks often requires less energy than solvent-based inks, further reducing the printing process's environmental footprint.

- Excellent Printability: Modern water-based inks offer excellent printability, adhesion, and durability on various substrates, making them a viable choice for various printing applications.

Beyond Environmental Benefits

Water-based flexographic inks offer additional advantages beyond their environmental benefits. They are often non-flammable, reducing fire hazards in printing facilities. Additionally, water-based inks can sometimes improve print quality by delivering sharper details and more vivid colors.

The Future of Printing

As environmental concerns continue to rise, water-based flexographic inks are likely to become the dominant choice in the printing industry. Their combination of environmental responsibility, safety advantages, and excellent printing capabilities make them a compelling solution for printers and consumers.

Qinghe Chemical's Leadership in Green Printing Solutions

Qinghe Chemical has established itself as a leader in green printing solutions with innovative water-based flexographic inks. The company's commitment to sustainability and environmental responsibility has set a benchmark for others in the industry. By prioritizing eco-friendly practices, Qinghe Chemical is shaping the future of flexographic printing ink and setting new standards for sustainable production.

Advantages of Water-Based Inks in Printing Industry

Water-based inks are gaining significant traction in the printing industry, not just for their environmental benefits but also for their impressive printing capabilities. Here's how they are revolutionizing the printing game:

- Environmentally Friendly: Water-based inks significantly reduce Volatile Organic Compound (VOC) emissions compared to solvent-based inks. VOCs contribute to smog and air pollution, so minimizing them protects air quality and human health. Additionally, water-based inks often utilize renewable resources and require less energy during drying, making the printing process more sustainable.

- Superior Print Quality: Modern water-based ink formulations rival solvent-based inks in terms of quality. They can deliver crisp details, vibrant colors, and sharp resolutions, ensuring high-quality prints that meet even the most demanding standards.

- Enhanced Versatility: Water-based inks demonstrate excellent adhesion to a wider range of substrates compared to solvent-based inks. This makes them suitable for printing on various materials, including paper, cardboard, plastic films, and even some textiles. This versatility allows printers to cater to diverse printing needs across different industries.

- Safety Advantages: Water-based inks typically contain fewer harmful chemicals compared to solvent-based inks. This translates to a safer working environment for printing press operators by minimizing exposure to hazardous substances. Additionally, water-based inks are often non-flammable, reducing fire risks within printing facilities.

A Sustainable Future for Printing

Water-based inks offer a compelling solution for printers and consumers alike. They combine exceptional printing performance with significant environmental and safety advantages. As environmental consciousness continues to grow, water-based inks are poised to become the dominant choice in the printing industry, paving the way for a more sustainable future.

The Evolution of Flexographic Inks

Flexographic inks have come a long way, and Qinghe Chemical has played a pivotal role in shaping the industry. With their innovative water-based flexo ink solutions, they have revolutionized sustainable printing practices and set new standards for environmental responsibility. As a leading supplier of water-based flexo inks, Qinghe Chemical has been at the forefront of driving the shift towards eco-friendly printing solutions.

Qinghe Chemical's Role in Shaping the Industry

Qinghe Chemical has been a trailblazer in the flexo ink industry, consistently pushing boundaries to develop cutting-edge water-based flexographic inks. Their commitment to research and development has led to significant advancements in sustainable printing, making them a trusted partner for businesses seeking environmentally responsible solutions. By pioneering the use of water-based ink for flexo printing, they have set a new benchmark for quality and sustainability.

Benefits of Water-Based Flexographic Inks for Sustainable Printing

Water-based flexographic inks rapidly transform the printing industry by offering a more sustainable alternative to traditional solvent-based inks. Here's how they contribute to eco-friendly printing practices:

- Reduced Environmental Impact: Water-based inks used in flexo-printing minimize Volatile Organic Compound (VOC) emissions significantly. VOCs contribute to smog and air pollution, harming human health and the environment. By minimizing VOCs, water-based inks promote cleaner air and a healthier planet.

- Improved Worker Safety: Since they contain minimal to no harmful solvents, water-based inks create a safer working environment for printing press operators. This reduces exposure to hazardous chemicals and associated health risks.

- Lower Waste Generation: Water-based inks are often easier to recycle than solvent-based inks. This minimizes waste generation and promotes practices aligned with a circular economy, where materials are reused and circulated for as long as possible.

- Energy Efficiency: The drying process for water-based inks generally requires less energy compared to solvent-based inks. This translates to a lower carbon footprint for the entire printing process.

- Sustainable Material Use: Water is a readily available and renewable resource, unlike petroleum-derived solvents in traditional inks. This makes water-based inks a more sustainable choice over the long term.

Beyond Sustainability

While environmental benefits are a major advantage, water-based flexographic inks offer additional merits:

- Excellent Printability: Modern water-based inks deliver high-quality printing with sharp details, vivid colors, and excellent adhesion on various substrates.

- Cost-Effectiveness: In some cases, water-based inks can offer cost advantages due to the elimination of solvent disposal fees and potentially lower energy consumption during drying.

The Future of Flexographic Printing

The numerous advantages of water-based flexographic inks make them the future of sustainable printing. As environmental concerns continue to rise and printing demands evolve, water-based inks will likely become the dominant choice for printers and consumers seeking a responsible and high-quality printing solution.

Shift Towards Water-Based Flexo Inks for Environmental and Health Reasons

As awareness around environmental and health concerns continues to grow, there is a clear shift towards water-based flexo inks within the printing industry. Businesses recognize the importance of reducing their carbon footprint and minimizing exposure to hazardous chemicals. With water-based inks for flexo printing, companies can achieve vibrant print results while prioritizing sustainability and employee well-being.

Superior Print Quality with Water-Based Flexographic Inks

Achieving Vibrant and Consistent Colors

Water-based flexographic inks produce vibrant and consistent colors, resulting in eye-catching and high-quality prints. With Qinghe Chemical's advanced technology, these inks are formulated to deliver superior color saturation and consistency across various substrates, meeting the demands of the most discerning clients.

Enhanced Print Resolution and Clarity

Water-based flexographic inks ensure enhanced print resolution and clarity, allowing for sharp and detailed images that truly stand out. This is made possible through the fine particle size of pigments in the ink, combined with precise application techniques, resulting in crisp, clear, and visually appealing prints.

Reduced Drying Time and Improved Print Speed

One key benefit of water-based flexo ink for printing is its reduced drying time, which translates to improved print speed without compromising quality. This efficiency increases productivity and allows quicker turnaround times on projects, making it a preferred choice for businesses seeking to optimize their printing processes.

Environmental Impact of Water-Based Flexo Inks

Qinghe Chemical's Commitment to Eco-Friendly Solutions

Qinghe Chemical has pioneered the development of eco-friendly solutions for the printing industry, with a strong focus on water-based flexographic inks. Their commitment to sustainable practices is evident in their extensive research and development efforts to reduce the environmental impact of flexographic printing ink. By prioritizing the use of renewable resources and minimizing waste, Qinghe Chemical continues to promote green printing solutions.

In addition to focusing on water-based flexographic inks, Qinghe Chemical has also made significant strides in reducing its carbon footprint and energy consumption. Through the implementation of energy-efficient manufacturing processes and facilities, the company has been able to minimize its environmental impact while still maintaining high-quality production standards. This dedication to sustainable practices not only benefits the planet but also sets a positive example for other companies in the printing industry.

Reduced Carbon Footprint and Energy Consumption

The adoption of water-based flexo inks has significantly reduced the carbon footprint and energy consumption associated with traditional solvent-based inks. The manufacturing process for water-based inks requires less energy and emits fewer greenhouse gases, making them a more environmentally friendly choice for printers. With Qinghe Chemical's innovative formulations, printers can achieve high-quality results while minimizing their environmental impact.

Additionally, water-based flexo inks offer the advantage of meeting regulatory standards and achieving green certifications. This is crucial for printers looking to comply with environmental regulations and demonstrate their commitment to sustainability. By using Qinghe Chemical's water-based inks, printers can ensure that their products meet the necessary criteria for eco-friendly printing, giving them a competitive edge in the market.

Meeting Regulatory Standards and Green Certifications

In today's increasingly environmentally conscious world, meeting regulatory standards and obtaining green certifications is crucial for businesses. Water-based flexographic inks meet these stringent requirements and exceed them by offering print operators a safer and healthier working environment. By choosing Qinghe Chemical as their flexographic ink supplier, printers can rest assured that they are aligning with the highest environmental standards.

In addition to meeting regulatory standards and obtaining green certifications, water-based flexographic inks also offer a wide range of applications and versatility. These inks can be used on various substrates, including paper, cardboard, and plastic, making them suitable for diverse printing needs. Whether for packaging, labels, or other printed materials, water-based flexo inks provide the flexibility and performance printers require to meet their clients' demands.

Versatility and Applications of Water-Based Flexo Inks

Water-based flexographic inks have revolutionized the printing industry, offering unparalleled versatility and applications across various substrates and packaging materials. Whether paper, cardboard, or plastic, these inks provide exceptional adhesion and vibrant color reproduction, making them a top choice for flexographic printing ink.

Suitable for Various Substrates and Packaging Materials

Water-based flexo inks are designed to adhere to a wide range of substrates, including non-porous materials like plastic films and foils, as well as absorbent surfaces such as paper and cardboard. This versatility makes them ideal for packaging applications across industries, from food and beverage to pharmaceuticals and personal care products. Their ability to maintain print quality on diverse materials makes them an invaluable asset for the packaging industry.

Water-based flexo inks are versatile in terms of substrate compatibility and offer an added advantage when it comes to food packaging and safety regulations. These inks are formulated to meet strict industry standards for food contact materials, ensuring they are safe for use with consumable products. This makes them ideal for brands seeking to comply with regulatory requirements while achieving high-quality printing results on their packaging materials.

Compatibility with Food Packaging and Safety Regulations

Water-based flexographic inks are revolutionizing the printing industry, particularly for food packaging applications. They offer a compelling combination of sustainability and safety, making them the preferred choice for eco-conscious brands:

- Compliance with Food Safety Regulations: Water-based inks are formulated without harmful solvents or chemicals that could migrate into food. This strict adherence to food safety regulations ensures the printed packaging remains safe for direct contact with food items. This eliminates concerns about potential contamination and prioritizes consumer health.

- Versatility for Diverse Packaging Needs: Water-based inks offer exceptional versatility beyond safety. They adhere well to various substrates commonly used in food packaging, including flexible packaging films, corrugated cardboard boxes, and labels. This allows printers to use water-based inks for a wide range of packaging applications without compromising quality or safety standards. Brands can maintain consistent, high-quality printing across their entire product line, from cereal boxes to candy bar wrappers, all while utilizing a sustainable printing solution.

The Advantages Go Beyond Sustainability

In addition to their environmental benefits, water-based inks can sometimes offer advantages in terms of cost-effectiveness due to reduced solvent disposal fees and potentially lower energy consumption during drying. Additionally, modern water-based inks deliver high-quality printing with sharp details and vivid colors, making them a compelling choice for brands seeking sustainability and visual appeal.

Meeting the Diverse Needs of the Printing Industry

In an ever-evolving printing industry, water-based flexographic inks are a versatile solution that meets the diverse needs of printers and converters alike. Whether it's high-speed label printing or intricate package designs, these inks offer consistent performance across a wide range of applications. Their adaptability to different printing processes makes them a go-to option for flexographic ink suppliers catering to various client requirements.

With their ability to adhere to diverse substrates while meeting stringent safety regulations, water-based flexographic inks have become a game-changer for the printing industry's sustainability efforts. As demand for eco-friendly printing solutions grows, these inks demonstrate adaptability and reliability across different applications.

The Future of Flexographic Printing with Water-Based Inks

Market Trends and Growth in Water-Based Flexo Ink Industry

The market for water-based flexographic inks is experiencing significant growth, driven by the increasing demand for sustainable printing solutions. As more companies prioritize eco-friendly practices, the flexo ink industry is witnessing a shift towards water-based inks for packaging and label printing. This trend is expected to continue as environmental consciousness becomes a priority for businesses and consumers alike.

As the demand for water-based flexographic inks continues to rise, there is a growing need for collaboration between ink suppliers and manufacturers to drive innovation and development in this sector. This partnership can lead to new formulations and technologies that further enhance the performance and sustainability of water-based inks, meeting the evolving needs of the packaging and label printing industry. By working closely with suppliers, companies can stay ahead of market trends and ensure that they are offering cutting-edge solutions to their customers.

Collaboration with Flexo Ink Suppliers for Innovation and Development

Flexographic ink suppliers are crucial in driving innovation and development within the industry. Collaborating with these suppliers allows for the creation of advanced formulations that meet the evolving needs of the market. By working closely with suppliers, printers can access cutting-edge water-based flexo inks that deliver superior print quality while adhering to sustainability standards.

In addition to developing high-quality inks, suppliers are also instrumental in providing technical support and expertise to printers. By collaborating closely with ink suppliers, printers can benefit from their knowledge of the latest industry trends and technologies. This partnership allows for co-creating innovative solutions that address specific printing challenges and enhance overall efficiency.

Embracing Sustainable Practices for a Brighter Future

The future of flexographic printing is undeniably sustainable, and water-based flexo inks are paving the way. This shift is driven by a powerful collaboration between environmentally conscious printers and consumers seeking eco-friendly choices.

Printers Leading the Charge

- Embracing Sustainability: Forward-thinking printers recognize the environmental impact of traditional inks and are adopting water-based inks as a responsible solution. This reduces VOC emissions, promotes safer working environments, and minimizes waste generation – all contributing to a healthier planet.

- Meeting Consumer Demand: As sustainability becomes a top priority for consumers, printers are aligning their practices with these values. Water-based inks allow them to offer packaging solutions that meet the growing demand for eco-friendly products.

Consumers Driving the Change

- Eco-Conscious Choices: Consumers are increasingly making purchasing decisions based on environmental impact. By seeking products with sustainable packaging (often indicated by water-based inks), they actively influence the printing industry.

- Future-Proofing Businesses: Printers who embrace water-based inks demonstrate environmental responsibility and future-proof their businesses. They position themselves to meet the evolving needs and expectations of a sustainability-focused customer base.

A Shared Future

This collaborative effort between environmentally responsible printers and eco-conscious consumers is shaping a sustainable future for the printing industry. Water-based flexo inks are at the forefront of this movement, offering a win-win solution for a healthier planet and a thriving printing industry.

Conclusion

Qinghe Chemical's Ongoing Contribution to Sustainable Printing

As a leader in the flexographic ink industry, Qinghe Chemical continues to pave the way for sustainable printing solutions. Their commitment to eco-friendly practices and innovative water-based flexo inks has set a new standard for the industry.

Advantages of Choosing Water-Based Flexographic Inks for Print Quality

Water-based flexographic inks are gaining traction in the printing industry, offering a compelling alternative to traditional solvent-based inks. While environmental benefits are a major draw, print quality remains crucial for printers. Here's how water-based inks stack up:

- Sustainability Champion: Water-based inks significantly reduce VOC emissions and promote safer work environments. Additionally, they often require less energy during drying and are easier to recycle, making them a sustainable choice.

- Capable Contender in Print Quality: Modern water-based ink formulations can deliver excellent printability with sharp details and vibrant colors, rivaling solvent-based inks in many aspects. They also demonstrate good adhesion to various substrates, making them suitable for different printing applications.

- Drying Efficiency: Water-based inks often boast faster drying times than solvent-based inks, which can improve printer efficiency and throughput.

However, it's important to note that:

- Solvent-based inks may still have an edge in certain applications: For specific high-performance or specialty printing needs, solvent-based inks might offer some advantages in terms of durability or resistance to certain chemicals.

- Matching the right ink to the job is key. Printers should carefully consider each printing project's specific requirements and choose the ink that best suits the desired outcome, whether it prioritizes environmental factors, exceptional color vibrancy, or maximum chemical resistance.

Overall, water-based flexographic inks offer environmentally solid benefits and excellent printing capabilities. As technology advances, water-based inks are likely to become an even more compelling choice for high-quality, sustainable printing.

The Future of Flexographic Printing with Environmentally Friendly Solutions

The future of flexographic printing lies in environmentally friendly solutions such as water-based inks. As the industry continues to shift towards sustainability, collaboration with flexo ink suppliers will drive innovation and development, creating a brighter and greener future for printing.