Introduction

Water-based ink is a versatile and eco-friendly alternative to traditional solvent-based inks. It is gaining popularity in the packaging industry for its sustainable and high-quality printing capabilities. As the demand for environmentally conscious packaging solutions continues to rise, understanding the benefits and applications of water-based ink is crucial for businesses looking to embrace sustainable printing technologies.

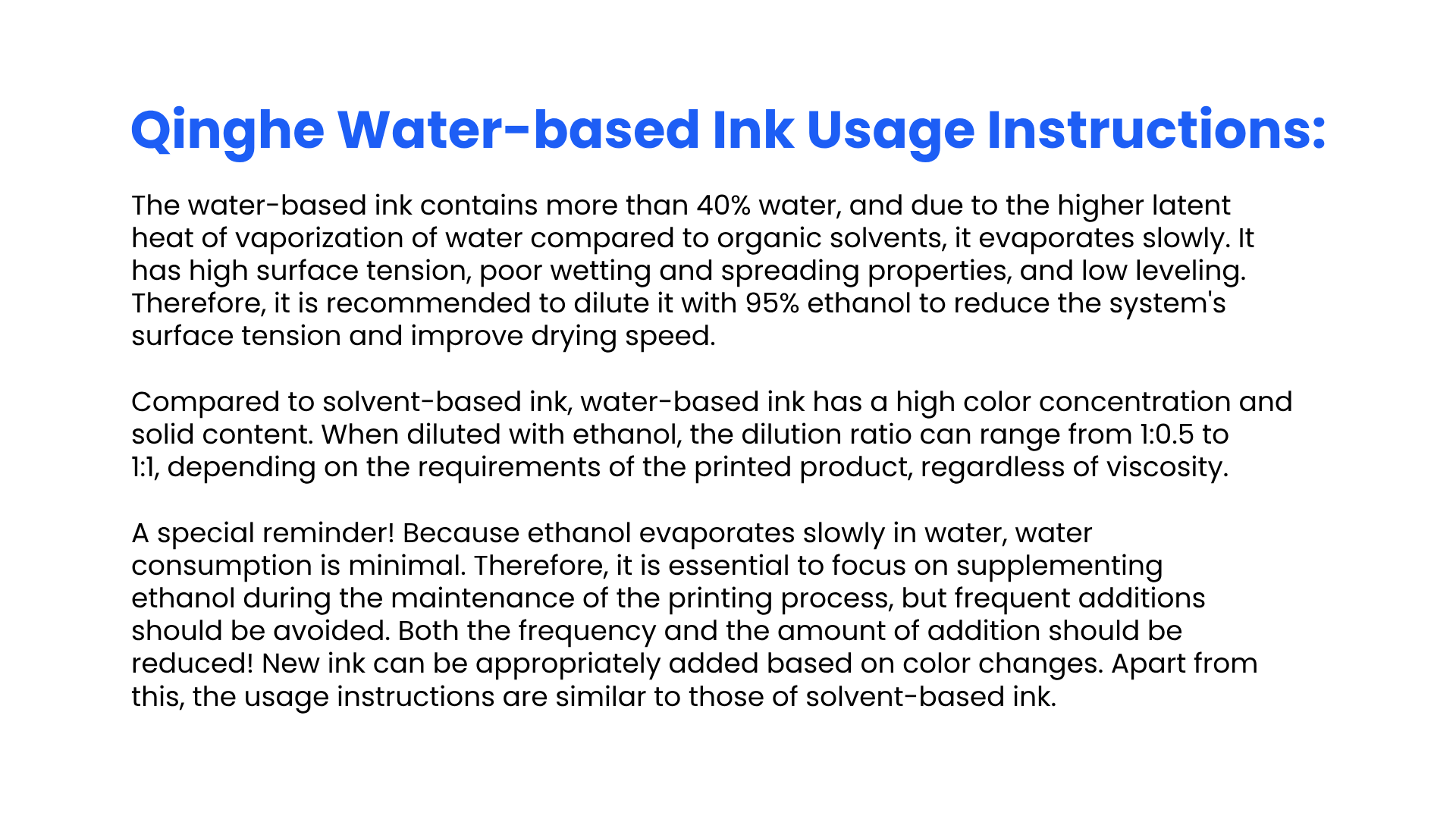

Understanding Water-Based Ink

Water-based ink is a type of ink that uses water as a solvent, making it non-toxic and safe for the environment. It contains pigments, binders, and additives that are finely dispersed in water to create vibrant colors for printing on various substrates.

Benefits of Water-Based Ink

Water-based inks are gaining popularity due to their several advantages:

- Eco-Friendly: Water-based inks contain minimal to no volatile organic compounds (VOCs) that harm air quality and human health.

- Superior Print Quality: These inks produce sharp, detailed prints with excellent color vibrancy, ideal for high-quality packaging.

- Enhanced Worker Safety: Water-based inks are less hazardous than solvent-based alternatives, reducing workers' exposure to harmful chemicals.

- Material Versatility: They adhere well to various materials, making them suitable for different packaging needs.

With their environmental benefits, improved print quality, worker safety focus, and material versatility, water-based inks offer a compelling solution for sustainable and high-quality packaging.

Applications of Water-Based Ink

Water-based ink is widely used in package printing due to its ability to produce sharp images and vibrant colors on paperboard, corrugated board, flexible packaging materials, and labels. Its versatility makes it ideal for food packaging, beverage cartons, cosmetic boxes, and other consumer goods.

What is Water-Based Ink

Water-based ink is a type of printing ink that uses water as a solvent, making it eco-friendly and safe for use in packaging. Its composition typically includes pigments, binders, and additives that are dispersed in water to create the ink. This makes it a sustainable alternative to traditional solvent-based inks, which contain harmful volatile organic compounds (VOCs) that pose health and environmental risks.

Definition and Composition

Water-based ink is formulated using water as the primary solvent and pigments, binders, and additives. The pigments provide color, while the binders hold the pigment particles together and adhere them to the printing surface. Additives enhance properties such as drying time, viscosity, and adhesion.

Key Characteristics

Water-based ink offers a compelling alternative to traditional inks, boasting several advantages:

- Eco-Friendly: Water-based ink minimizes environmental impact and is made with non-toxic components and minimal VOC emissions.

- Vibrant Prints: Despite its eco-friendly nature, water-based ink delivers excellent print quality with sharp details and rich colors.

- Fast Drying & Easy Cleanup: Water-based ink dries quickly and cleans up easily with water, reducing downtime and simplifying printing.

- Enhanced Safety: Unlike solvent-based inks containing harmful chemicals, water-based ink is non-toxic and safer for workers and consumers, making it a healthier choice.

Water-based ink stands out for its environmental responsibility, high-quality output, user-friendliness, and safety, making it a preferred choice for businesses and consumers.

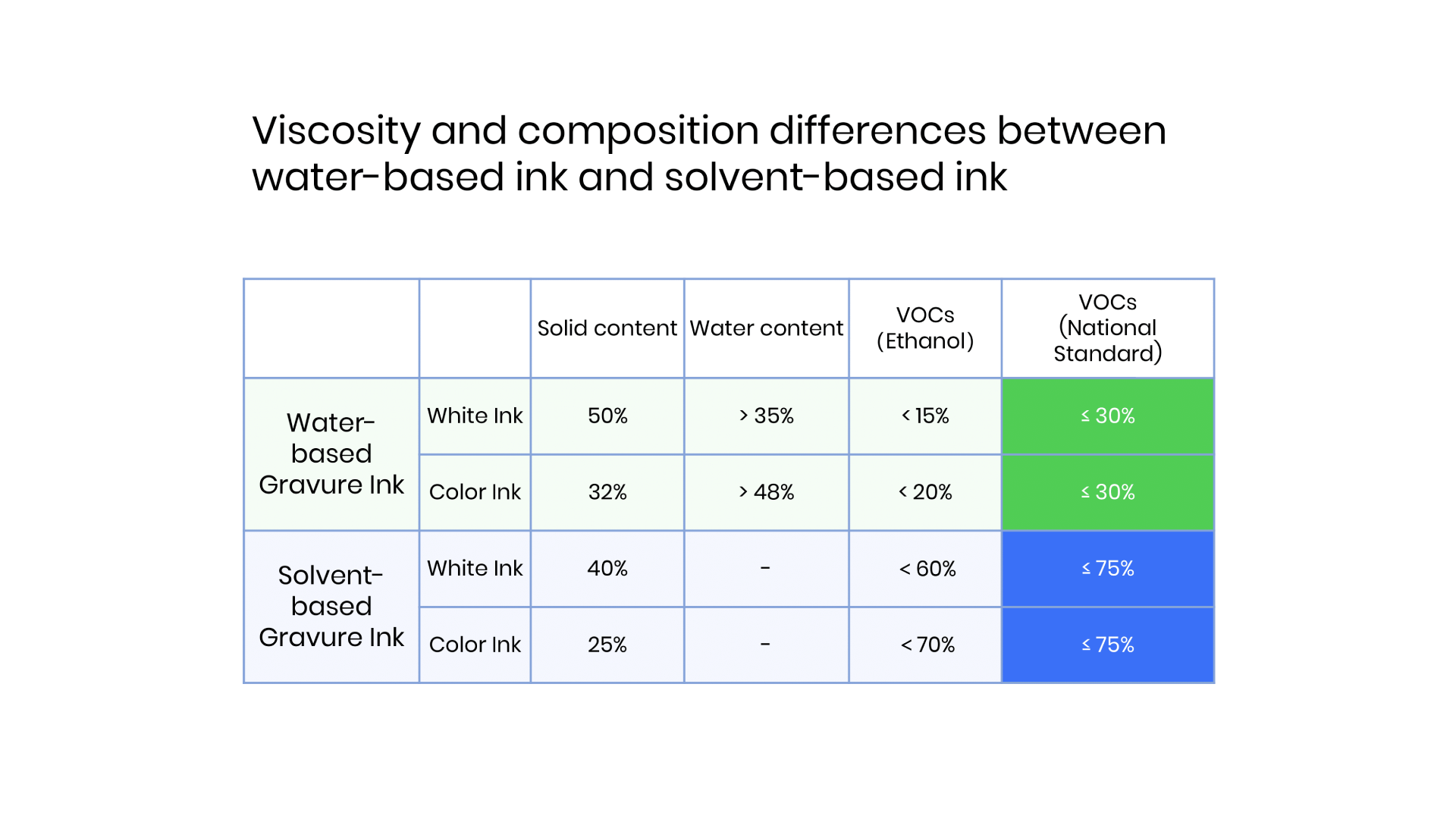

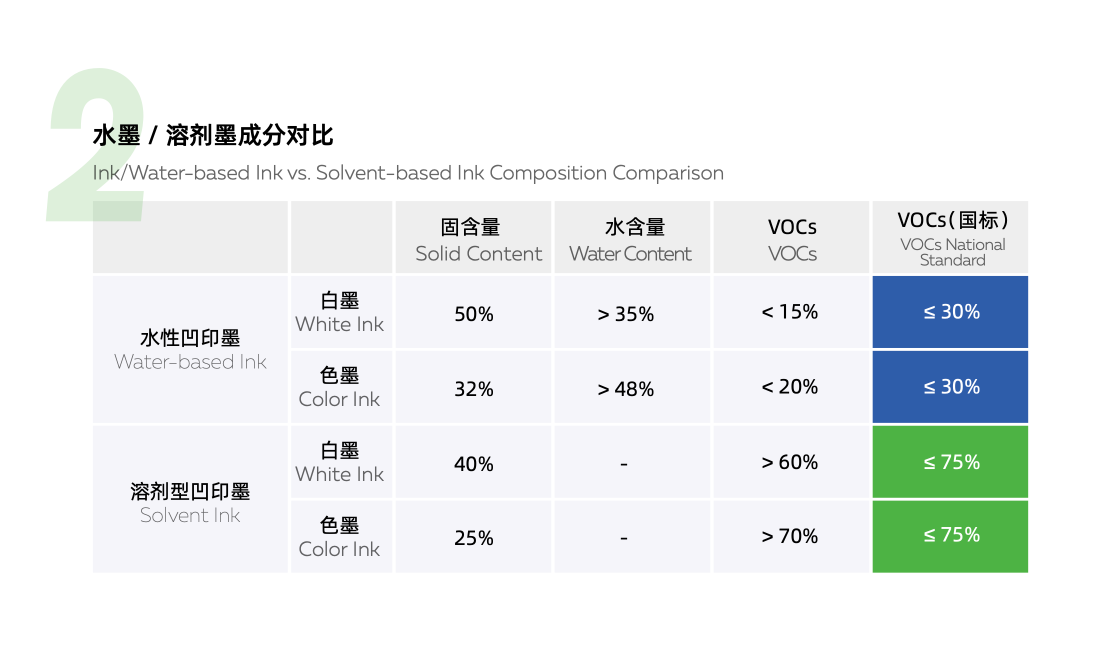

Comparison with Solvent-Based Inks

In contrast to solvent-based inks, which release harmful VOCs into the atmosphere during printing and drying processes, water-based inks have significantly lower VOC emissions. This makes them a safer option for printers and consumers alike, primarily when used in packaging applications where direct contact with food or skin may occur.

In addition to their lower VOC emissions, water-based inks also offer improved safety and sustainability benefits for packaging applications. Unlike solvent-based inks, water-based inks do not contain hazardous air pollutants, making them a more environmentally friendly choice. This aligns with the growing consumer demand for eco-friendly and non-toxic packaging solutions, providing a competitive advantage for brands that prioritize sustainability.

Advantages of Water-Based Ink for Package Printing

Improved Print Quality

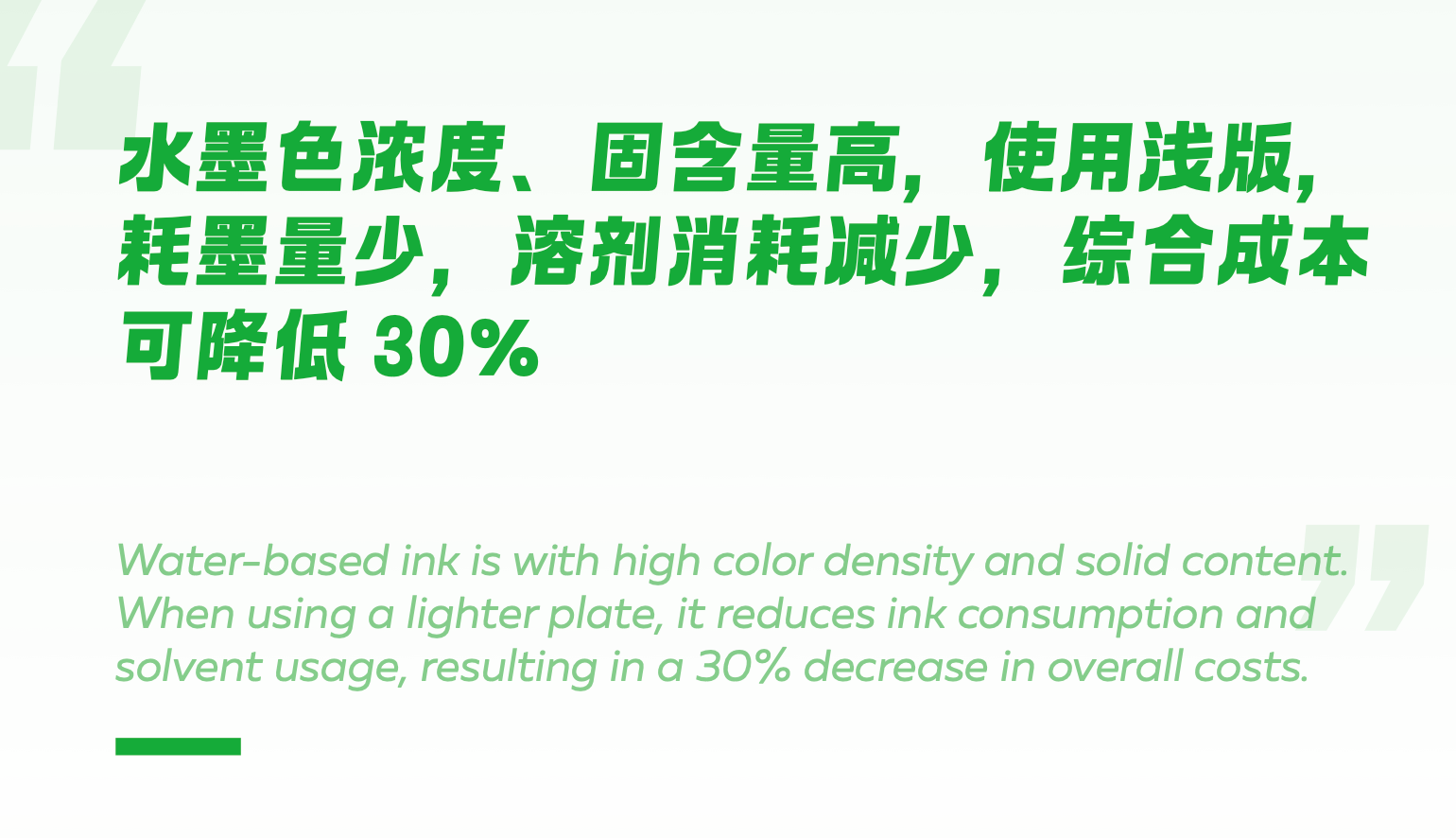

Water-based inks offer superior print quality, producing vibrant and crisp images on packaging materials. The inks penetrate the substrate, resulting in excellent adhesion and color retention, ensuring that the packaging design remains visually appealing throughout its shelf life.

Furthermore, water-based inks are formulated without harsh chemicals, making them a more environmentally friendly option for packaging. This aligns with the growing consumer demand for sustainable and eco-friendly products, allowing brands to appeal to a broader audience. By choosing water-based inks for packaging materials, companies can demonstrate their commitment to reducing their environmental impact and contribute to a more sustainable future.

Eco-Friendly Packaging

Utilizing water-based ink for package printing promotes eco-friendly packaging solutions. These inks are non-toxic, emit minimal volatile organic compounds (VOCs), and are biodegradable, aligning with sustainable packaging initiatives and reducing environmental impact.

Regulatory Compliance for Food Packaging

Water-based inks are also environmentally friendly, as they do not contain volatile organic compounds (VOCs) that can harm the environment and contribute to air pollution. This makes them a sustainable choice for food packaging printing, aligning with the growing consumer demand for eco-friendly products. By using water-based inks, food packaging manufacturers can demonstrate their commitment to environmental responsibility while ensuring compliance with regulatory standards.

Water-Based Printing Technology

Water-based ink has revolutionized the printing industry with its eco-friendly and high-quality results. It is widely used in various printing methods, including flexographic printing, screen printing, and textile printing.

Flexographic Printing

Flexographic printing is a popular choice for package printing due to its ability to print on a variety of substrates. Water-based inks for flexographic printing offer vibrant colors and excellent adhesion, making them ideal for producing high-quality packaging materials.

Flexographic printing is also known for its cost-effectiveness and efficiency in producing large volumes of packaging materials. The fast-drying nature of water-based inks used in flexographic printing allows for high-speed production, making it a time-saving option for businesses with tight deadlines. Additionally, the ability to print on various substrates such as plastic, paper, and metallic films makes flexographic printing a versatile choice for packaging needs.

Screen Printing

Water-based screen printing ink is known for its versatility and ability to create intricate designs on packaging materials. It provides exceptional color vibrancy and durability, making it a preferred choice for brands looking to enhance their product packaging.

Water-based screen printing ink is not only versatile and durable but also environmentally friendly, making it an attractive option for eco-conscious brands. With its water-based formulation, this type of ink reduces the use of harmful chemicals and solvents, contributing to a more sustainable packaging production process. In addition to creating stunning designs, brands can also promote their commitment to sustainability by using water-based screen printing ink on their packaging materials.

Textile Printing

In the realm of package printing, water-based textile ink plays a crucial role in creating eye-catching designs on fabric packaging materials. Its eco-friendly composition and vibrant color options make it an attractive choice for sustainable packaging solutions.

By embracing water-based ink technology in flexographic, screen, and textile printing methods, brands can elevate their packaging designs while reducing their environmental impact. This innovative approach to package printing not only enhances the visual appeal of products but also contributes to sustainable practices within the industry.

Best Water-Based Screen Printing Ink

Water-based screen printing ink is a versatile and sustainable choice for package printing. Its key features include low VOC content, fast drying time, and excellent adhesion to various substrates. These inks are perfect for applications such as food packaging, corrugated boxes, and retail displays.

Features and Benefits

When it comes to eco-friendly and high-quality package printing, water-based screen printing inks offer several advantages:

- Superior Color and Opacity: Water-based inks deliver vibrant colors and exceptional opacity, creating eye-catching and professional packaging designs.

- Environmentally Friendly: Made with a focus on sustainability, these inks reduce environmental impact compared to traditional options.

- Easy Cleanup and Maintenance: Water-based inks simplify cleaning, minimizing downtime and ensuring efficient production workflows.

- Excellent Adhesion: They adhere well to various substrates, such as paper, cardboard, and plastic, guaranteeing durable and long-lasting printed packaging.

- Versatility Across Industries: Water-based inks are perfect for a wide range of packaging needs, from food and beverage to cosmetics and pharmaceuticals.

Water-based screen printing inks combine eco-friendliness with superior print quality and versatility, making them a perfect choice for businesses seeking high-impact and sustainable packaging solutions.

Applications and End-User Experience

From vibrant product labels to eye-catching promotional materials, water-based screen printing inks deliver outstanding results across a wide range of package printing applications. End-users appreciate the eco-friendly nature of these inks and the vibrant, long-lasting prints they produce on packaging materials.

Comparison with Other Printing Inks

Compared to solvent-based inks, water-based screen printing inks offer a safer and more sustainable option for package printing. They provide excellent adhesion to substrates without compromising on print quality or durability. This makes them an ideal choice for brands looking to enhance their packaging while minimizing their environmental footprint.

In addition to being safer and more sustainable, water-based screen printing inks offer a wider range of color options, allowing brands to create eye-catching and vibrant packaging designs. This versatility allows brands to stand out on the shelf and attract consumers' attention, ultimately leading to increased sales and brand recognition. With water-based inks, brands can achieve both their environmental and marketing goals simultaneously.

Qinghe Chemical's Role in Water-Based Ink Innovation

Qinghe Chemical has a rich history and extensive expertise in developing high-quality water-based inks for various printing applications. With years of experience, the company has become a leading innovator in the field of sustainable printing solutions, particularly in the development of water-based ink for flexo printing and water-based textile ink.

History and Expertise

Qinghe Chemical has been at the forefront of water-based ink innovation for decades, constantly pushing the boundaries of what is possible with eco-friendly printing solutions. Their team of experts has a deep understanding of the intricacies of water-based inks, allowing them to create products that meet the highest industry standards while minimizing environmental impact.

Contribution to Sustainable Printing

The company's commitment to sustainable printing is evident in its extensive portfolio of water-based inks for flexographic and textile printing. These products not only deliver exceptional print quality but also significantly reduce VOC emissions and overall environmental footprint, making them ideal choices for eco-conscious packaging manufacturers.

Partnerships and Collaborations

Qinghe Chemical actively collaborates with industry leaders to further advance the adoption of water-based printing technology. By partnering with packaging companies and print shops, they can tailor their products to specific needs and ensure seamless integration into existing production processes, driving widespread adoption of water-based ink for sustainable packaging.

By leveraging its expertise, commitment to sustainability, and collaborative approach, Qinghe Chemical continues to play a pivotal role in advancing water-based ink innovation for package printing applications. As consumer demand for eco-friendly packaging grows, their contributions are poised to shape the future of green printing solutions.

The Future of Water-Based Printing Technology

Water-based ink is the future of sustainable packaging, offering eco-friendly solutions for the printing industry. With advancements in water-based printing technology, the potential for innovation and growth is endless. Qinghe Chemical is at the forefront of this revolution, leading the way in green printing solutions.

Embracing Water-Based Ink for Sustainable Packaging

As more businesses prioritize sustainability, water-based ink has become a crucial component in creating eco-friendly packaging solutions. Its low environmental impact and compliance with regulatory standards make it an ideal choice for brands looking to reduce their carbon footprint while maintaining high-quality packaging.

The future of water-based printing technology is bright, with continuous advancements in formulation and application methods. As consumer demand for sustainable products grows, so does the need for innovative printing solutions that prioritize environmental responsibility without compromising on quality.

Qinghe Chemical: Leading the Way in Green Printing Solutions

Qinghe Chemical's commitment to sustainable printing practices has established them as leaders in providing high-quality water-based inks for flexographic and textile printing applications. Their expertise and dedication to innovation make them a valuable partner for businesses seeking to embrace eco-friendly packaging solutions.

By embracing water-based ink for sustainable packaging, businesses can contribute to a greener future while meeting consumer demands for eco-friendly products. The future of water-based printing technology holds great promise, and Qinghe Chemical continues to lead the way in providing green printing solutions that prioritize sustainability without sacrificing quality or performance.