Introduction

When it comes to packaging, plastic shrink wrap has become a popular choice for businesses looking to protect and secure their products. However, the type of ink used for printing on this material is often overlooked. Today, we'll delve into the benefits of using water-based ink for plastic shrink wrap, explore why it's superior for shrink wrap printing, and understand its advantages for plastic packaging.

The Benefits of Water-Based Ink for Plastic Shrink Wrap

Water-based inks offer a compelling alternative to traditional solvent-based inks when printed on plastic shrink wrap. Here are some of the key benefits they provide:

- Reduced Environmental Impact: Water-based inks are formulated with minimal to no harmful solvents, making them much more eco-friendly than solvent-based inks. This reduces air pollution and minimizes the risk of harmful chemicals leaching into the environment.

- Safer for Food Packaging: Since water-based inks are free from harmful chemicals, they are a safer choice for printing on shrink wrap used for food packaging. This ensures that food products are not contaminated by potentially toxic solvents.

- Strong Adhesion and Print Quality: Despite being water-based, these inks offer excellent adhesion to plastic shrink wrap. This ensures the printed design remains clear and sharp even after shrinking.

- Easier Cleanup: Water-based inks are easier to clean than solvent-based inks. This translates to a more efficient printing process and reduces the need for harsh cleaning chemicals.

By choosing water-based inks for your plastic shrink wrap printing needs, you can contribute to a greener environment, ensure the safety of your products, and achieve high-quality printing results.

Why Water-Based Ink is Superior for Shrink Wrap Printing

Water-based inks are becoming increasingly popular for shrink wrap printing due to their environmental and safety advantages. Here's why water-based inks are a superior choice for shrink wrap printing:

- Enhanced Durability and Adhesion: Water-based inks form a strong bond with the plastic surface, ensuring the design remains intact even after the heat shrinking process. This compatibility prevents cracking or peeling, resulting in a professional and long-lasting finish.

- Vibrant and Crisp Printing: Water-based inks are formulated to deliver sharper details and brighter colors compared to traditional solvent-based inks. This translates to eye-catching and high-quality prints for your shrink wrapped products.

- Environmentally Friendly: Water-based inks are more sustainable as they contain minimal to no harmful solvents. This reduces the printing process's environmental impact and contributes to a greener supply chain.

- Safer for Food Packaging: With stricter regulations on food contact materials, water-based inks offer peace of mind. They minimize the risk of harmful chemicals leaching from the packaging into food, protecting consumers from potential health concerns.

Water-based inks offer a compelling combination of superior printing quality, environmental friendliness, and safety for food packaging applications. They are a clear choice for businesses seeking a sustainable and responsible approach to shrink wrap printing.

The Advantages of Water-Based Ink for Plastic Packaging

Water-based ink offers several advantages over traditional solvent-based inks when it comes to plastic packaging. Here's why you should consider switching:

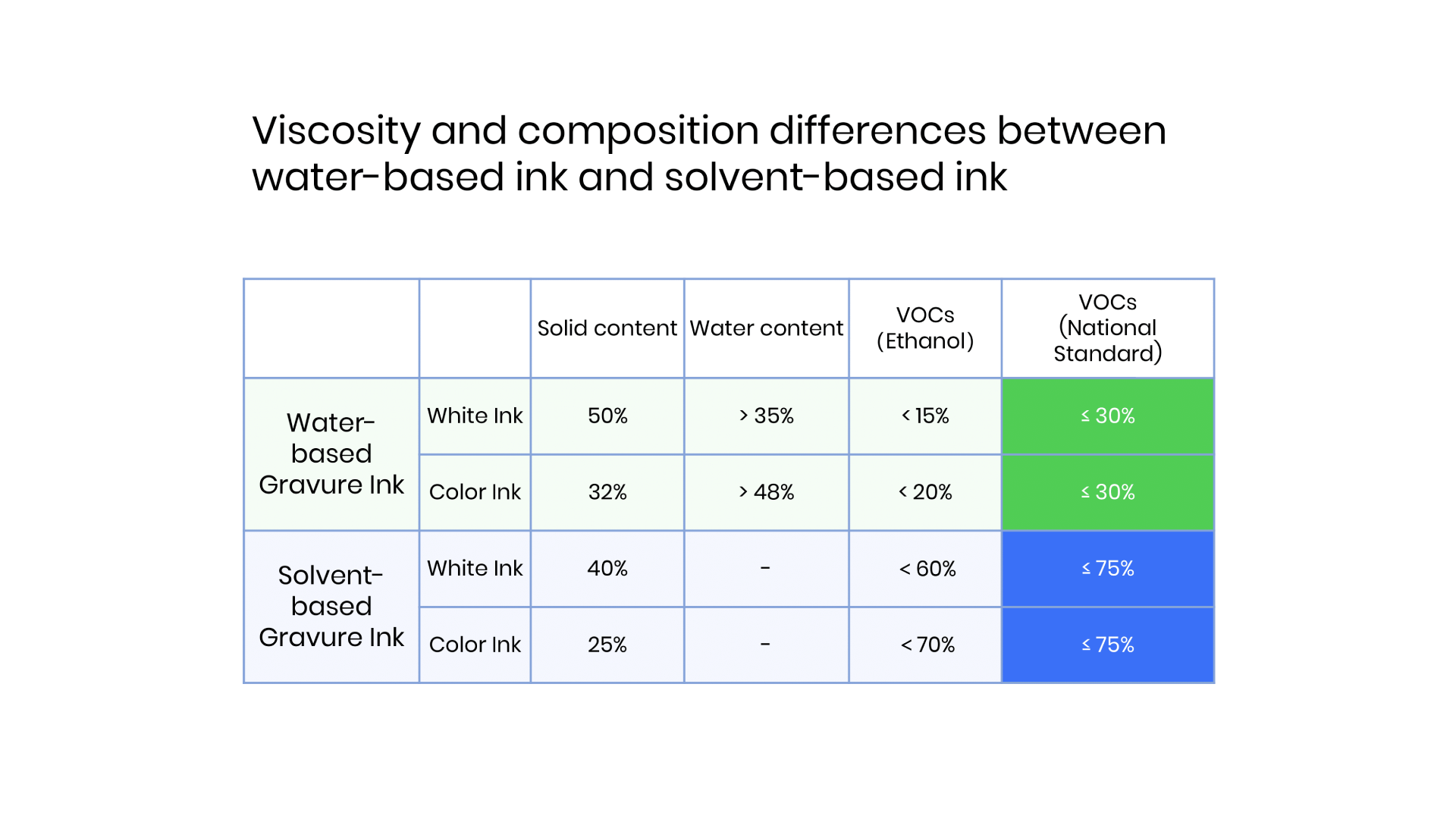

- Eco-Friendly: Water-based inks are free from harmful volatile organic compounds (VOCs) that pollute the air and contribute to health problems. Thus, they are a more sustainable choice for environmentally conscious businesses.

- Vibrant Colors & Durability: Water-based ink delivers superior print quality on plastic shrink wrap. It achieves vivid colors that grab attention on store shelves, and its ability to withstand the material's stretching ensures those colors stay bright throughout the product's lifecycle.

- Safer for Workers and Consumers: Since water-based inks lack harsh chemicals, they create a safer working environment for printing press operators. Additionally, the ink's non-toxic nature makes it ideal for packaging items that come into contact with food or beverages.

By choosing water-based ink for your plastic packaging, you're not only making a positive impact on the environment but also ensuring your products stand out with high-quality, long-lasting visuals.

The Environmental Impact of Water-Based Ink

Qinghe Chemical's Commitment to Eco-Friendly Solutions

At Qinghe Chemical, we provide eco-friendly solutions for the printing industry. Our water-based ink for plastic shrink wrap is formulated with non-toxic, biodegradable materials, ensuring minimal environmental impact.

As a leader in the printing industry, we understand the importance of sustainable printing practices. That's why we have developed a range of eco-friendly solutions that not only meet our customers' high-quality standards but also minimize their environmental impact. Our commitment to using non-toxic, biodegradable materials in our water-based ink for plastic shrink wrap is just one example of how we are dedicated to promoting sustainability in the printing industry.

The Importance of Sustainable Printing Practices

In today's environmentally conscious world, sustainable practices are no longer a nicety but a necessity. The packaging industry, in particular, can significantly reduce its environmental impact by adopting sustainable printing processes. Here's how:

- Water-Based Inks for Reduced Emissions and Waste: Switching from traditional solvent-based inks to water-based alternatives is a significant step towards sustainable printing. Water-based inks produce fewer harmful emissions during printing, resulting in a cleaner environment. Additionally, they contribute less to waste as they are more easily recyclable and biodegradable.

- Eco-Friendly Inks Meet Consumer Demand: The growing demand for eco-friendly products presents a compelling reason to adopt sustainable printing practices. By utilizing water-based inks and minimizing environmental impact, businesses can demonstrate their commitment to sustainability, aligning themselves with consumer preferences and gaining a competitive edge in the market.

Sustainable printing practices using water-based inks offer a win-win situation. They benefit the environment by reducing emissions and waste while creating a competitive advantage for businesses catering to the growing demand for eco-friendly products.

Reducing Environmental Footprint with Water-Based Ink

Water-based ink offers a sustainable alternative to traditional solvent-based inks, which release volatile organic compounds (VOCs) into the atmosphere. Businesses can play a vital role in minimizing air pollution and environmental degradation by choosing water-based ink for plastic wrap packaging.

Water-based ink also offers improved safety for workers in the packaging industry. Unlike solvent-based inks, water-based inks do not pose a risk of flammability or explosion, creating a safer working environment. This can lead to reduced insurance costs and fewer workplace accidents, ultimately benefiting employees and businesses.

Enhanced Safety for Food Packaging

Water-based ink is an ideal choice for food packaging as it ensures the safety of consumers. Unlike solvent-based inks, water-based inks do not contain harmful chemicals that can leach into food products, providing both manufacturers and consumers peace of mind. This makes water-based ink a superior choice for companies prioritizing food safety in their packaging materials.

Ensuring Food Safety with Water-Based Ink

Water-based ink offers a non-toxic and non-hazardous solution for printing on plastic shrink wrap. It ensures that the ink does not contaminate the food products it comes into contact with. This is especially crucial for companies in the food industry that must comply with strict regulations and standards to guarantee the safety of their products.

How Water-Based Ink Protects Consumers

By using water-based ink for plastic wrap packaging, manufacturers can protect consumers from potential health risks associated with toxic chemicals in traditional solvent-based inks. This commitment to consumer safety can also enhance brand reputation and build trust among customers who prioritize safe and sustainable packaging options.

Meeting Regulatory Standards for Food Contact Materials

Water-based ink has become increasingly popular due to its ability to meet stringent regulatory standards for food contact materials. Manufacturers no longer have to worry about compliance issues or recall related to unsafe packaging materials when using water-based ink, making it a reliable choice for companies seeking to uphold high-quality and safe packaging standards.

Water-based ink not only meets regulatory standards for food-contact materials but also offers superior print quality compared to other types of ink. The vibrant colors and crisp lines achieved with water-based ink make packaging designs stand out on the shelf, attracting consumers and boosting brand recognition. This combination of safety and visual appeal makes water-based ink a top choice for companies looking to make a lasting impression with their product packaging.

Superior Print Quality with Water-Based Ink

Water-based ink offers exceptional print quality for plastic shrink wrap, ensuring vibrant and eye-catching colors that grab attention on the shelf. The ink's ability to adhere to the plastic wrap's surface results in sharp and crisp images, making your packaging stand out from the competition.

Achieving Vibrant Colors on Plastic Shrink Wrap

With water-based ink technology, you can achieve a wide range of vibrant colors on plastic shrink wrap, enhancing the visual appeal of your packaging. Whether you need bold and bright hues or more subtle tones, water-based ink delivers consistent and stunning color reproduction that catches consumers' eyes.

Water-Based Ink's Ability to withstand the Stretching of Plastic Wrap

Unlike traditional solvent-based inks, water-based ink maintains its integrity even when subjected to plastic shrink wrap's stretching and wrapping process. This ensures that your branding and messaging remain intact without any distortion or loss of clarity, providing a professional and polished appearance for your products.

The Durability and Longevity of Water-Based Ink Prints

Water-based ink creates durable prints on plastic wrap packaging that can withstand handling, transportation, and various environmental conditions without fading or smudging. This longevity ensures that your branding remains vibrant and impactful throughout the product lifecycle, maintaining a strong visual presence in the market.

Water-based ink prints on plastic wrap packaging also offer an eco-friendly advantage, as they are free from harmful solvents and chemicals commonly found in other types of ink. This makes them a sustainable choice for brands looking to reduce their environmental impact and appeal to eco-conscious consumers. Using water-based ink prints, you can align your brand with sustainability efforts and attract a growing market segment that prioritizes environmentally friendly products.

Cost-Effectiveness and Efficiency

In today's competitive market, businesses must find ways to save money and improve efficiency. When it comes to packaging, using water-based ink technology for plastic shrink wrap can result in significant cost savings. Water-based ink requires less maintenance and cleanup than solvent-based inks and has a longer shelf life, reducing the frequency of ink replacement and saving on material costs.

Saving Money with Water-Based Ink Technology

Companies can reduce their production costs by switching to water-based ink for shrink wrap printing. Water-based inks are more affordable than solvent-based inks and require fewer resources for cleanup and disposal. Additionally, the improved print quality and durability of water-based ink means fewer reprints and less waste, further contributing to cost savings.

The Economic Benefits of Water-Based Ink for Packaging

Water-based ink offers a compelling alternative to traditional packaging inks, bringing economic and environmental advantages. Here are several ways water-based ink can benefit your business:

- Cost-Competitive Materials and Production: Water-based inks are often less expensive than solvent-based inks. Additionally, their water content reduces the need for volatile organic compounds (VOCs) during production, potentially lowering regulatory compliance costs.

- Enhanced Brand Image and Market Differentiation: Consumers are increasingly environmentally conscious and value brands that prioritize sustainability. Using water-based inks, your company can project a more eco-friendly image, giving you a competitive edge in the marketplace.

- Improved Worker Safety and Reduced Environmental Impact: Water-based inks contain fewer harmful chemicals than solvent-based ones. This translates to a safer working environment for employees and minimizes the release of harmful VOCs into the atmosphere.

Water-based inks offer businesses a win-win situation. They can reduce costs and help establish a reputation for environmental responsibility, attracting today's sustainability-focused consumers.

Streamlining Production Processes with Water-Based Ink

Another advantage of water-based ink technology is its ability to streamline plastic shrink wrap printing production processes. Unlike solvent-based inks that require lengthy drying times and specialized equipment, water-based inks dry quickly at room temperature, allowing for faster turnaround times and increased productivity. This efficiency saves time and reduces energy consumption, contributing to overall cost-effectiveness.

The Future of Shrink Wrap Printing

With the continuous advancements in water-based ink technology, the future of shrink wrap printing is looking brighter than ever. These innovations have improved adhesion, faster drying times, and enhanced color vibrancy on plastic shrink wrap. As more companies prioritize sustainable practices, the potential for water-based ink in shrink wrap printing is becoming increasingly evident.

Innovations in Water-Based Ink Technology

In recent years, there have been significant breakthroughs in water-based ink technology specifically tailored for plastic shrink wrap. These innovations have improved print quality and durability, making water-based ink a viable option for high-quality packaging needs. With these advancements, businesses can expect to achieve vibrant and long-lasting prints on their plastic shrink packaging.

Embracing the Potential of Water-Based Ink for Shrink Wrap

As more businesses recognize the environmental and safety benefits of water-based ink, there has been a growing shift toward embracing this technology for shrink wrap printing. Water-based ink's potential to meet regulatory standards while providing superior print quality makes it an attractive choice for companies looking to elevate their packaging solutions.

Qinghe Chemical's Vision for the Future of Plastic Packaging

At Qinghe Chemical, our vision for the future of plastic packaging revolves around sustainability and innovation. We are committed to pushing the boundaries of water-based ink technology to ensure that it continues to meet and exceed industry standards for plastic shrink wrap printing. By investing in research and development, we aim to lead the way in eco-friendly and high-quality plastic packaging solutions.

Furthermore, we are dedicated to exploring alternative materials and processes that reduce plastic packaging's environmental impact. Our goal is to develop new, sustainable options for our customers that minimize waste and energy consumption while maintaining the high level of performance they expect. By staying at the forefront of emerging technologies and materials, we can continue to offer innovative solutions that align with our commitment to sustainability.

Embrac Sustainable Printing Practices with Water-Based Ink

Water-based ink for plastic shrink wrap is the way of the future. Its print quality, environmental impact, safety, and cost-effectiveness benefits make it a superior choice for packaging. By embracing sustainable printing practices with water-based ink, we can ensure vibrant, durable prints on plastic wrap while reducing our environmental footprint.

Making the Switch: Advantages of Water-Based Ink for Shrink Wrap

Making the switch to water-based ink for plastic shrink wrap is a no-brainer. Not only does it offer superior print quality and durability, but it also ensures food safety and meets regulatory standards for food-contact materials. With water-based ink technology constantly evolving, it is undoubtedly the future of shrink wrap printing.

Embracing sustainable printing practices with water-based ink is not just a responsible choice; it's also a smart one. Reducing our environmental footprint and saving money through cost-effective production processes can streamline our operations while contributing to a healthier planet.

The Case for Water-Based Ink in Plastic Packaging

The case for water-based ink in plastic packaging is clear: it offers unparalleled print quality, safety, and sustainability benefits. As more companies recognize the advantages of water-based ink technology, we can expect to see a widespread shift towards eco-friendly solutions in the packaging industry.