Introduction

In today's ever-evolving packaging industry, the rise of water-based inks has revolutionized the way we print on plastic shrink film. As consumer demand for sustainable solutions grows, so does the need for eco-friendly options in plastic packaging. This is where Qinghe Chemical comes into play, offering innovative water-based inks that transform how we approach shrink wrap and heat shrink wrap applications.

The Rise of Water-Based Inks in Packaging

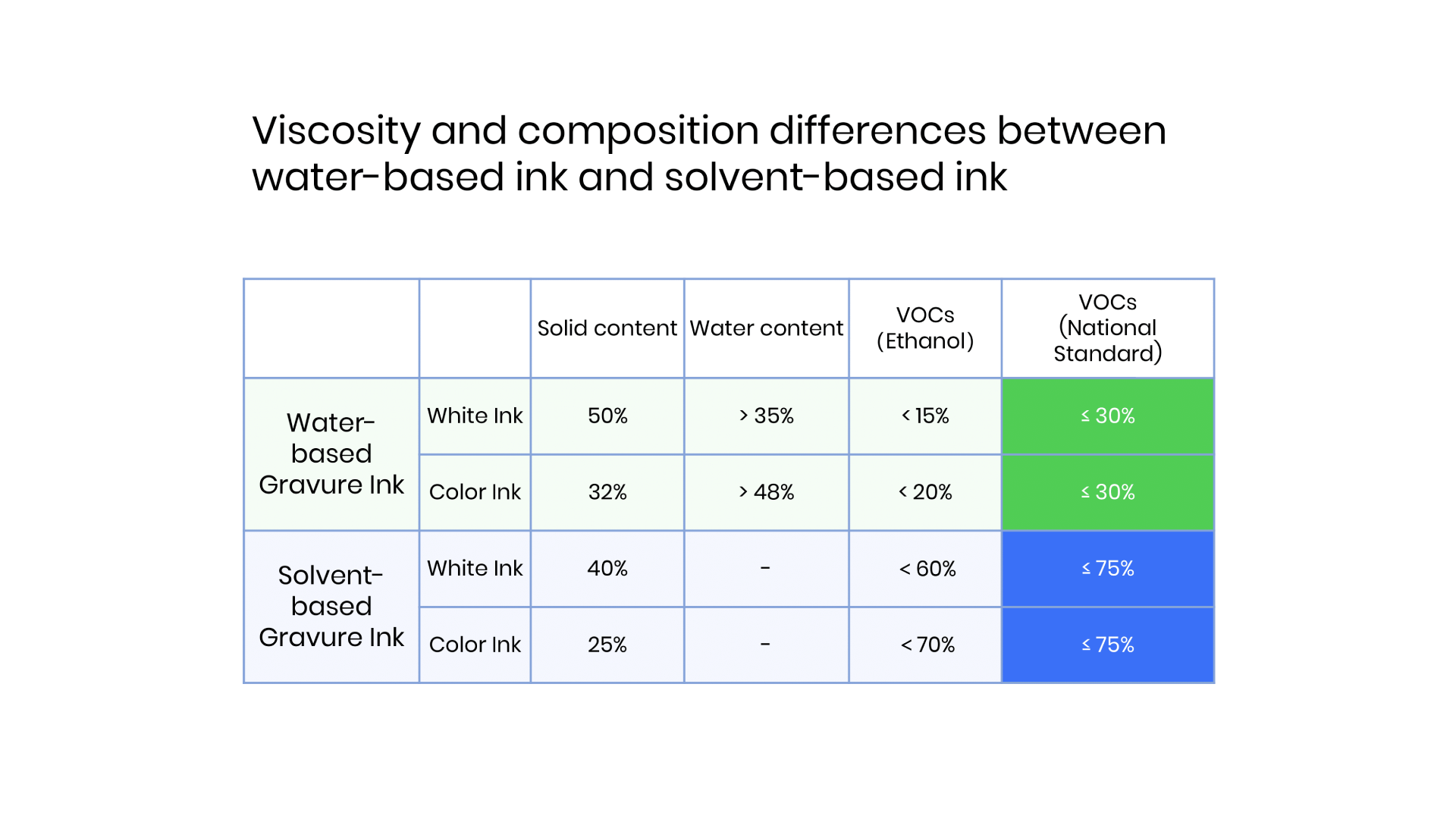

The traditional use of solvent-based inks in plastic packaging has long been a concern due to their environmental impact and potential health hazards for workers. With the shift towards water-based inks, there's been a significant reduction in volatile organic compound (VOC) emissions and overall environmental impact.

The shift towards water-based inks has also improved safety for workers in the packaging industry. Solvent-based inks contain hazardous chemicals that can pose health risks to those who come into contact with them. Using water-based inks exposes workers to fewer harmful substances, creating a healthier work environment overall.

Benefits of Using Water-Based Inks on Plastic Shrink Film

Water-based inks are a superior alternative to traditional solvent-based inks for printing on plastic shrink film. They offer many advantages, making them a win-win for both the environment and your business. Here are some key benefits:

- Improved Worker Safety: Water-based inks eliminate harmful solvents, reducing worker exposure to hazardous chemicals and creating a healthier work environment.

- Enhanced Print Quality: Water-based inks can achieve excellent color vibrancy and detail, resulting in visually appealing and high-quality packaging.

- Reduced Environmental Impact: Water-based inks significantly minimize volatile organic compound (VOC) emissions, contributing to cleaner air and a smaller environmental footprint.

- Stronger Adhesion: Water-based inks form a durable bond with plastic shrink film, ensuring the printed design remains intact and crisp even after the shrinking process. This translates to long-lasting, professional-looking packaging.

- Preserves Film Integrity: Water-based inks are less likely to cause warping or damage to the plastic film during printing, maintaining a smooth and consistent finish for high-quality packaging.

By switching to water-based inks for your plastic shrink film printing needs, you're not only making a responsible environmental choice but also ensuring the safety of your workers and achieving superior print quality for your brand.

Introduction to Qinghe Chemical

Qinghe Chemical is at the forefront of this transformation, developing innovative water-based inks designed explicitly for shrink wrap bags, wrappers near me, and other plastic shrink film applications. Their commitment to sustainability and product excellence has made them a leading provider in the industry.

Qinghe Chemical's water-based inks offer numerous advantages over traditional solvent-based inks. They are more environmentally friendly and provide superior adhesion to plastic substrates, resulting in vibrant and long-lasting colors. Additionally, these inks are formulated to dry quickly, increasing productivity and reducing downtime for shrink-wrap bags and film manufacturers.

Advantages of Water-Based Inks

Water-based inks offer several key advantages when printing on plastic shrink film. Firstly, they have a significantly reduced environmental impact compared to traditional solvent-based inks, making them a more sustainable choice for packaging. Secondly, these inks are known for improving workers' safety by emitting fewer volatile organic compounds (VOCs) and reducing the risk of hazardous chemical exposure. Lastly, water-based inks enhance print quality, producing vibrant and crisp images on shrink wrap bags and other plastic packaging materials.

1. Reduced Environmental Impact

With the packaging industry's increasing focus on sustainability, the use of water-based inks has gained traction due to their minimal impact on the environment. These eco-friendly inks contain lower levels of harmful chemicals and VOCs, making them a more responsible choice for companies looking to reduce their carbon footprint. Using water-based inks on plastic shrink film allows businesses to align with consumer preferences for environmentally conscious products while maintaining high-quality packaging.

2. Improved Safety for Workers

One significant advantage of water-based inks is their contribution to a safer working environment. Unlike traditional solvent-based inks, which release toxic fumes during printing processes, water-based alternatives emit minimal VOCs and odors, reducing health risks for employees operating shrink wrappers near me or handling shrink film. This improvement in workplace safety protects workers' well-being and enhances overall productivity by minimizing downtime due to health-related issues.

3. Enhanced Print Quality

Water-based inks outshine their solvent-based counterparts when it comes to achieving vibrant and visually appealing prints on plastic shrink film. The advanced formulation of these inks allows for sharper details, brighter colors, and better adhesion to various plastic packaging materials. As a result, businesses can create eye-catching designs on shrink wrap bags and other products while ensuring that the printed images remain durable throughout handling and transportation processes.

Furthermore, water-based inks are also more environmentally friendly than solvent-based ones, as they contain fewer volatile organic compounds (VOCs) and other harmful chemicals. This makes them preferable for businesses looking to reduce their environmental impact and meet sustainability goals. By using water-based inks to print plastic shrink film, companies can demonstrate their commitment to eco-friendly practices while achieving high-quality, vibrant prints that attract consumers.

Challenges of Traditional Inks on Plastic Shrink Film

1. Limited Compatibility with Plastic Surfaces

Traditional inks often struggle to adhere to plastic shrink film due to its smooth and non-porous surface, leading to smudging and poor print quality. This lack of compatibility can result in wasted materials and increased production costs as the need for reprints and rewrapping becomes common. Moreover, using traditional inks on plastic surfaces can also pose environmental concerns, as the chemicals in these inks may not be eco-friendly and could contribute to pollution. Additionally, the inability of traditional inks to bond with plastic surfaces may lead to a higher consumption of ink, further adding to environmental impact through increased waste.

2. Environmental Concerns

The use of traditional inks on plastic shrink film poses environmental concerns and presents occupational health hazards for workers involved in the printing and packaging process. Exposure to VOCs and HAPs during the production and application of these inks can lead to respiratory issues, skin irritation, and other adverse health effects for employees. Additionally, prolonged exposure to these hazardous emissions may increase the risk of long-term health complications, making it imperative that businesses prioritize using safer alternatives to protect their workers' well-being.

3. Occupational Health Hazards

Workers involved in plastic shrink film production and printing processes are also at risk of exposure to harmful chemical fumes emitted during the manufacturing and printing stages. These fumes can lead to headaches, dizziness, and nausea, creating an uncomfortable and potentially hazardous work environment. Additionally, prolonged exposure to these chemical fumes may result in more serious health issues, such as respiratory problems or even neurological disorders.

Qinghe Chemical's Innovative Approach

Development of Water-Based Inks for Shrink Wrap Applications

Qinghe Chemical has been developing water-based inks specifically designed for plastic shrink film and shrink wrap applications. Our team of experts has conducted extensive research to create inks that adhere perfectly to plastic surfaces, ensuring vibrant and long-lasting prints on shrink wrap bags and heat shrink wrap products.

Collaboration with Leading Packaging Manufacturers

We have established successful partnerships with top packaging manufacturers to tailor our water-based inks to their specific needs. By working closely with industry leaders, we have fine-tuned our formulations for optimal performance on various types of plastic packaging, including shrink film and shrink wrappers near me.

Success Stories in the Plastic Packaging Industry

Our innovative approach has led to numerous success stories in plastic packaging. From improved printing efficiency to cost savings and enhanced product quality, Qinghe Chemical's water-based inks have revolutionized the use of plastic shrink wrap in packaging solutions.

Our water-based inks have improved the efficiency of printing on plastic shrink wrap and significantly reduced the environmental impact of packaging production. By eliminating the need for solvent-based inks, we have helped our clients reduce their carbon footprint and contribute to a more sustainable packaging industry. This has been a success not only for our clients' bottom line but also for the planet.

Case Studies: Water-Based Inks vs Traditional Inks

Performance Comparison on Different Types of Shrink Film

The results of comparing the performance of water-based inks and traditional inks on various types of plastic shrink film are clear. Water-based inks demonstrate superior adhesion and color vibrancy across different substrates, including PVC, PET, and polyolefin films. Their flexibility and heat resistance also outperform traditional inks in shrink wrap bags and other packaging applications.

Customer Testimonials on Cost Savings and Productivity Gains

Customers who have switched to water-based inks for their plastic shrink film printing have reported significant cost savings and productivity gains. The faster drying time of water-based inks has increased throughput on their shrink wrappers, resulting in higher production volumes without compromising quality. These testimonials highlight the tangible benefits of using water-based inks for plastic packaging applications.

Impact on Final Product Quality

The impact of using water-based inks on final product quality cannot be overstated. The vibrant colors, sharp details, and consistent coverage achieved with water-based inks elevate the visual appeal of shrink film packaging. Additionally, the absence of volatile organic compounds (VOCs) ensures that the printed plastic shrink film maintains its integrity without any undesirable odors or environmental harm associated with traditional solvent-based inks.

The Future of Inks for Plastic Shrink Film

Market Trends and Consumer Preferences

As the demand for sustainable packaging solutions grows, market trends significantly shift towards eco-friendly options like plastic shrink film. Consumers are increasingly seeking products that are not only visually appealing but also environmentally responsible, driving the need for water-based inks in plastic packaging.

Technological Innovations in Shrink Wrappers and Heat Shrink Wrap

With technological advancements, shrink wrappers and heat shrink wrap machines are becoming more efficient and versatile. Manufacturers are developing equipment that can handle various types of plastic shrink film, offering customization options to meet the specific needs of different industries and products.

Expansion of Qinghe Chemical's Product Line

Qinghe Chemical is at the forefront of this evolution, expanding its product line to include a wider range of water-based inks specifically designed for plastic shrink film applications. Their commitment to innovation and sustainability positions them as a leader in providing high-quality, environmentally friendly solutions for the packaging industry.

Make the Switch: Benefits of Water-Based Inks for Plastic Shrink Film

When it comes to plastic shrink film, the benefits of switching to water-based inks are undeniable. Not only does it offer improved print quality and reduced environmental impact, but it also ensures worker safety and meets consumer demand for sustainable packaging solutions. Embracing sustainable solutions in packaging is no longer just a trend—it's a necessity for businesses looking to stay competitive in today's market.

Using water-based inks on plastic shrink film allows businesses to enjoy cost savings, enhanced productivity, and improved final product quality. The switch to water-based inks demonstrates a commitment to environmental responsibility and sets a positive example for others in the industry.

Embracing Sustainable Solutions in Packaging

As consumer awareness of environmental issues continues to grow, embracing sustainable solutions in packaging is crucial for businesses looking to maintain their market share and reputation. By using water-based inks on plastic shrink film, companies can demonstrate their commitment to sustainability while meeting consumer demand for eco-friendly products.

Qinghe Chemical: Pioneering the Future of Shrink Film Inks

Qinghe Chemical's innovative approach to developing water-based inks for shrink wrap applications has positioned them as industry pioneers. Their collaboration with leading packaging manufacturers and success stories in the plastic packaging industry demonstrate their dedication to driving positive change and shaping the future of shrink film inks.

Switching to water-based inks for plastic shrink film is clear. It benefits individual businesses and contributes to a larger movement towards sustainability within the packaging industry. Qinghe Chemical continues to lead the way with its innovative products and partnerships. It is setting a new standard for eco-friendly solutions that will shape the future of packaging materials and practices.